INSTRUCTIONS FOR:

LAMBDA TESTER &

SIMULATOR

Thank you for purchasing a Sealey Product.

Manufactured to a high standard this product will, if used

according to these instructions and properly maintained,

give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE

THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLYAND WITH CARE FOR THE PURPOSE

FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAYCAUSE DAMAGE

OR PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY.

PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

01284 757500

E-mail:

sales@sealey.co.uk

01284 703534

For Jack Sealey Ltd. Sole importer into the UK of Sealey Professional Tools.

Lambda Tester & Simulator

Model VS925

73/23/EEC Low Voltage Directive.

89/336/EEC EMC Directive.

93/68/EEC Marketing Directive.

14th September 2005

Declaration of Conformity

Signed by Mark Sweetman

Model: VS925

We, the sole importer into the UK, declare that the product listed here is in

conformity with the following standards and directives. The construction file

for this product is held by the Manufacturer and may be inspected, by a

national authority, upon request to Jack Sealey Ltd.

VS925 - 1 - 200905

General Maintenance: The Lambda tester is a sensitive electronic

instrument and should be treated as such. Avoid high temperatures,

mechanical shock and damp environments. Occasional inspection of

cables for damage and/or loose connections together with battery

replacement is the only required maintenance.

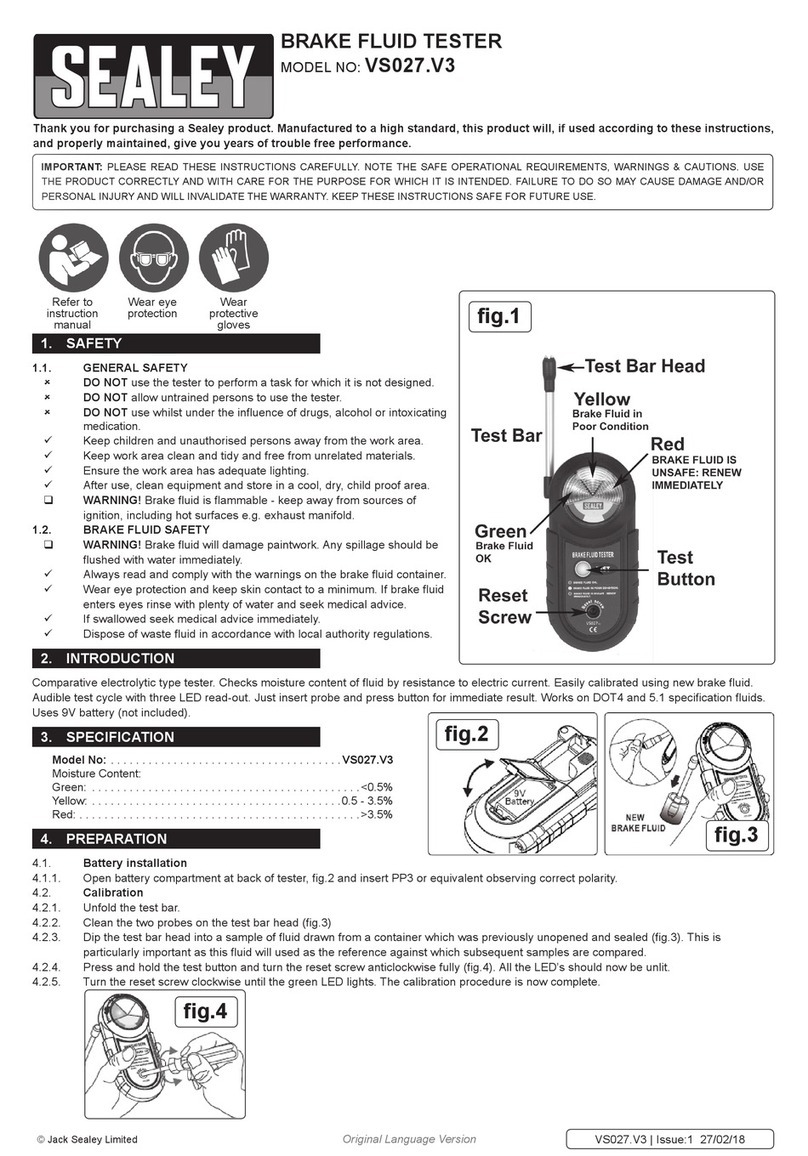

Battery Replacement: When the battery voltage is low the single

red LED in the ident panel will illuminate.

(1) Remove the battery lid on the rear of the instrument by sliding in

the direction of the arrow.

(2) Unplug the wire connector and install a new, good quality, alkaline

type PP3 9V battery. Replace the battery lid.

Specifications:

Power Supply: One 9V alkaline type PP3 battery.

Connectors: One wire-piercing clip and one black ground

clip.

Display: Output crossover of signal displayed

as a light path in the LED array.

Ident Panel: Indicators to identify heater supply, ECU

supply, open circuit LED, ground supply

and low battery indication.

Test Leads: Quality silicone leads able to withstand

high temperatures.

Enclosure: ABS.

Dimensions: 145mm x 80mm x 34mm.

Warranty 1 year. The warranty is invalid if the instrument

has been subject to misuse or abuse. The

warranty does not cover batteries or any other

materials that wear out during normal operation of

the instrument.

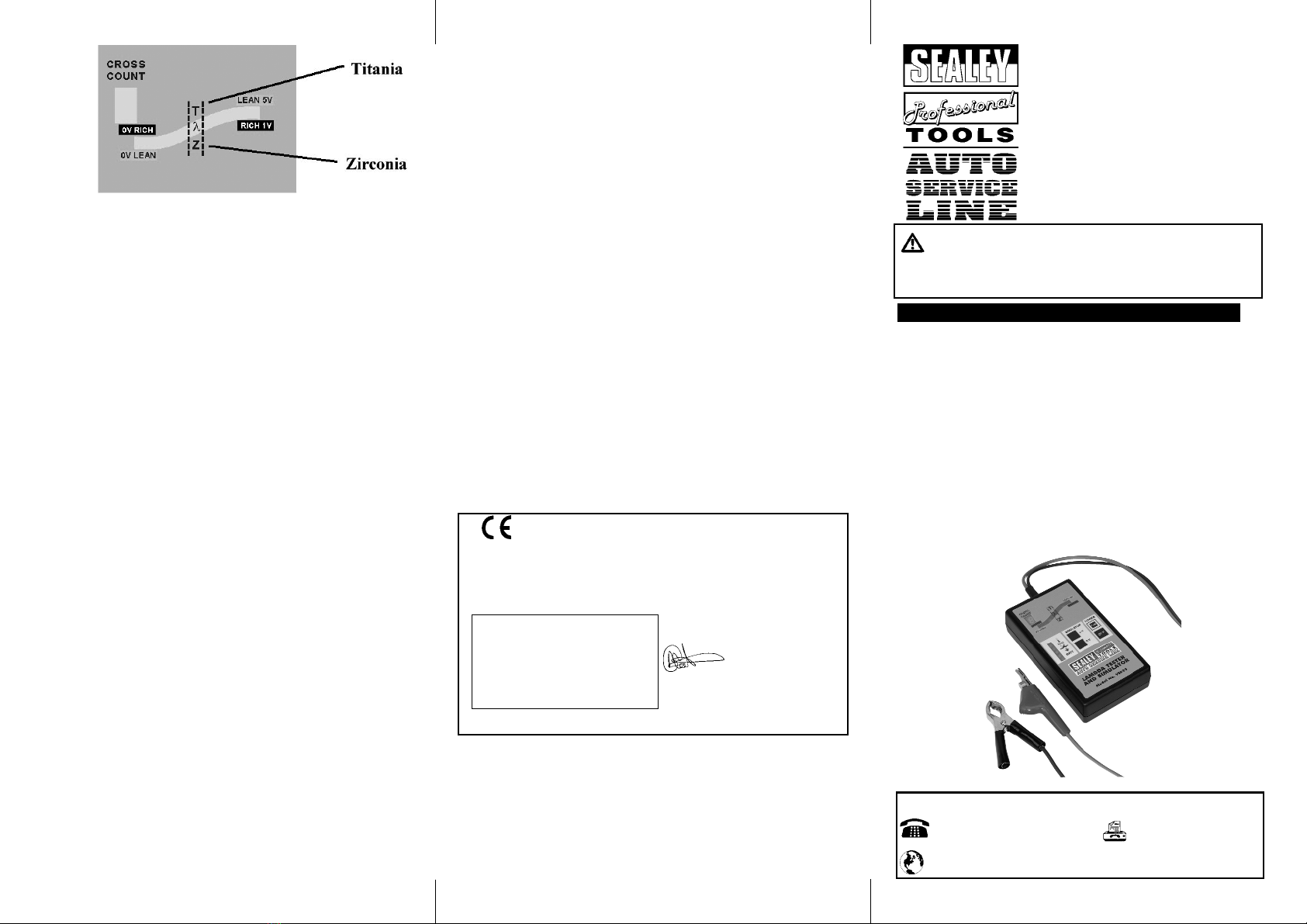

LAMBDA WINDOW:TITANIA SENSOR: RICH & LEAN

SIGNALS ARE REVERSED.

Normally a Lambda/O2sensor operating under acceptable

conditions will result in the display LED array illuminating

continuously from lean to rich then back again as shown in FIG 3.

This pattern is repeated constantly. If there is a fault with the

Lambda/O2sensor or ECU the normal pattern described above

will not occur and the activity in the LED array will be limited to

either the rich or lean sector of the display window, dependant on

the type of fault.

As a basic test to begin to identify the source of the fault, use the

simulation feature of the tester to introduce a RICH or LEAN

SIGNAL and observe whether this produces a change in the LED

activity present. By pressing +V (Titania, press 0V) the tester

will transmit a RICH signal to the ECU.

If the circuit is functioning correctly the mixture will be weakened

and the result should be apparent by a decrease in the engine

speed occurring. Ideally, a four-gas analyser should be used to

verify that the mixture strength varies in response to the false

signals introduced. No reaction would suggest a wiring/connection

problem or faulty ECU. Faulty fuelling, faulty ignition or faulty

management sensors (located on the engine) could also produce

the same effect. If the response to the simulated signals IS

detected, then the Lambda/O2sensor should be inspected,

cleaned and tested and substitution or replacement undertaken as

necessary.

In some management systems a simulated signal may flag into

the systems memory and be shown as a fault code when

checked with a code reader. Some management systems also

contain a "limp home device" which activates when the Lambda

sensor fails. The ECU will input a firm value signal of approx.

500mV to the sensor to allow the vehicle to be driven at low

speeds. This condition will show on the display area of the tester

when either the first or the second LED is lit constantly in the

Lambda window.

1. SAFETY INSTRUCTIONS

pWARNING! Ensure Health and Safety, local authority and

general workshop practice regulations are adhered to when

using tools.

7DO NOT use tester if damaged.

3Maintain tester in good and clean condition for best and

safest performance.

3Ensure that a vehicle which has been jacked up is

adequately supported with axle stands.

3Wear approved eye protection. Afull range of personal safety

equipment is available from your Sealey dealer.

3Wear suitable clothing to avoid snagging. Do not wear

jewellery and tie back long hair.

3Account for all tools and parts being used and do not leave

any on or near the engine.

NOTE: It is our policy to continually improve products and as such we reserve

the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this equipment.

WARRANTY: Guarantee is 12 months from purchase date, proof of which

will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us

on 01284 757525 and leave your full name and address, including

Fig 3

www.sealey.co.uk