© 2010 Utilicor Technologies Inc.

4

Introduction

Utilicor Technologies Inc. (Utilicor)

Utilicor is the exclusive manufacturer and distributor of a field-proven,

keyhole coring and pavement reinstatement system. Our mission is to

develop new, innovative and cost effective technologies for the utility

industry.

Utilicor Process

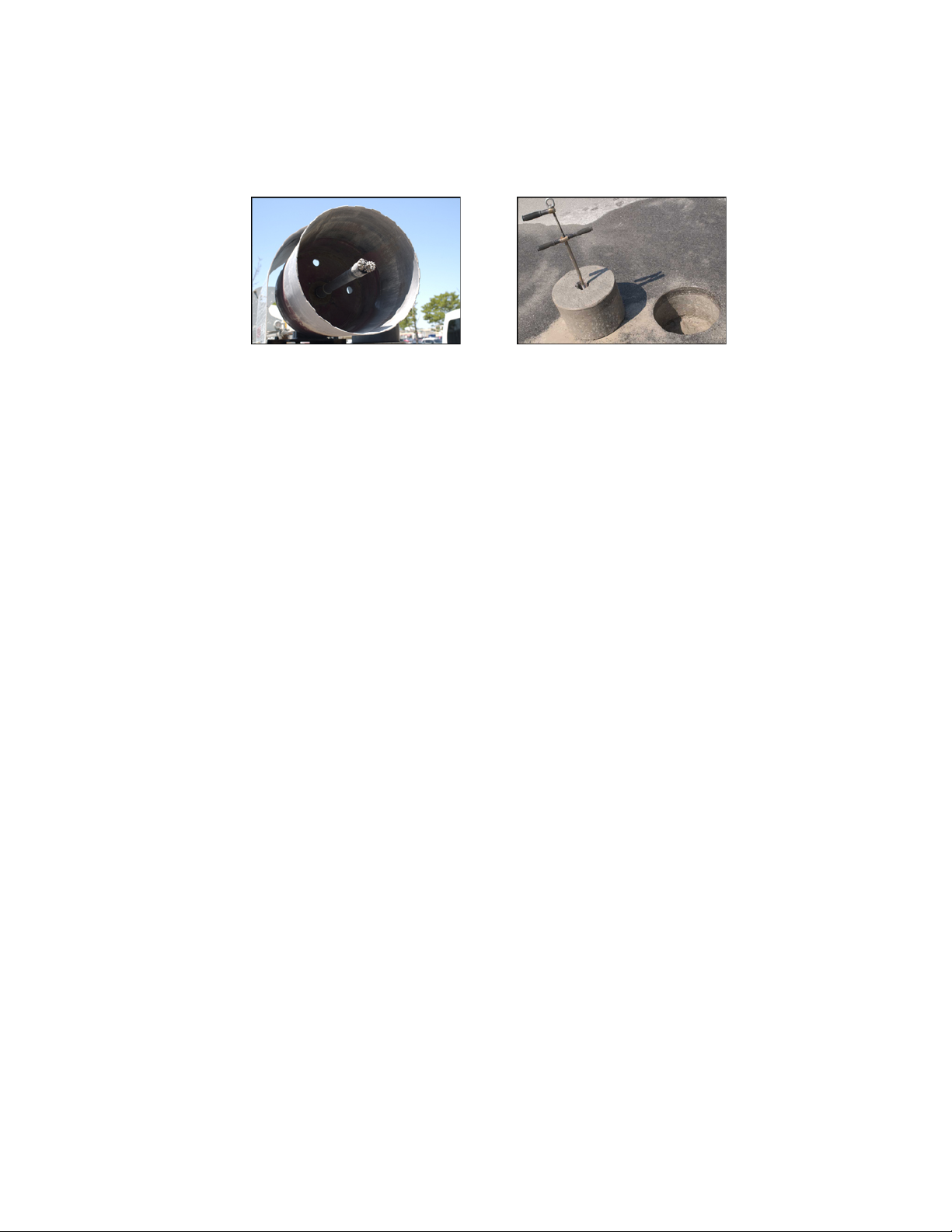

The Utilicor process, referred to as "Utilicoring", combines the purpose-built,

field proven, truck or minicor-2™ skid-steer mounted, Utilicor Rotary Coring

Unit with Utilibond™, a proprietary bonding compound, that have been

specially engineered for coring and the permanent reinstatement of the

cored coupon in asphalt, asphalt-concrete, concrete and reinforced concrete

road surfaces, and concrete sidewalks. The process has been approved as a

permanent pavement repair by a number of transportation authorities in

both Canada and the USA since 1992, on thousands of keyhole excavations,

with ZERO failures.

Utilibond™, our proprietary core bonding compound is an integral part of the

reinstatement process and has been independently tested and shown to

create a bond (in less than 30 minutes at 70ºF) that is stronger than the

original pavement and is capable of supporting the combined weight of five

transit buses in under half an hour.

The Purpose of The Operations Manual

This manual is intended as a reference guide for operating and maintaining

the Utilicor coring equipment and performing core reinstatements using

Utilibond™. It is designed to familiarize the operator with the main elements

of the process, and to answer common questions, but does not replace

comprehensive, on-the-job training performed by a competent trainer.

Neither should it be considered as a replacement for common sense or a

substitute for the maintenance requirements of the vehicle or equipment on

which your Utilicor unit has been installed or mounted. Most importantly, this

operations manual is intended to be used in conjunction with the internal