4 of 11

03103436-A10015 Rev. C July 16, 2021

Maintenance

The following maintenance guidelines detail how to inspect seat belts. If any of these problem

conditions are found, the entire seat belt system must be replaced.

Seat Belt Webbing

Examine seat belt webbing in the seat system for cuts, fraying, extreme or unusual wear, signicant dirt,

or extreme faded color due to exposure to ultraviolet rays.

D‑Loop Web Guide

The D‑Loop Web Guide is an area where there is a signicant amount of webbing movement during the

use of the seat belt system. If the web is cut or frayed at the D‑Loop Web Guide, the entire belt system

must be replaced.

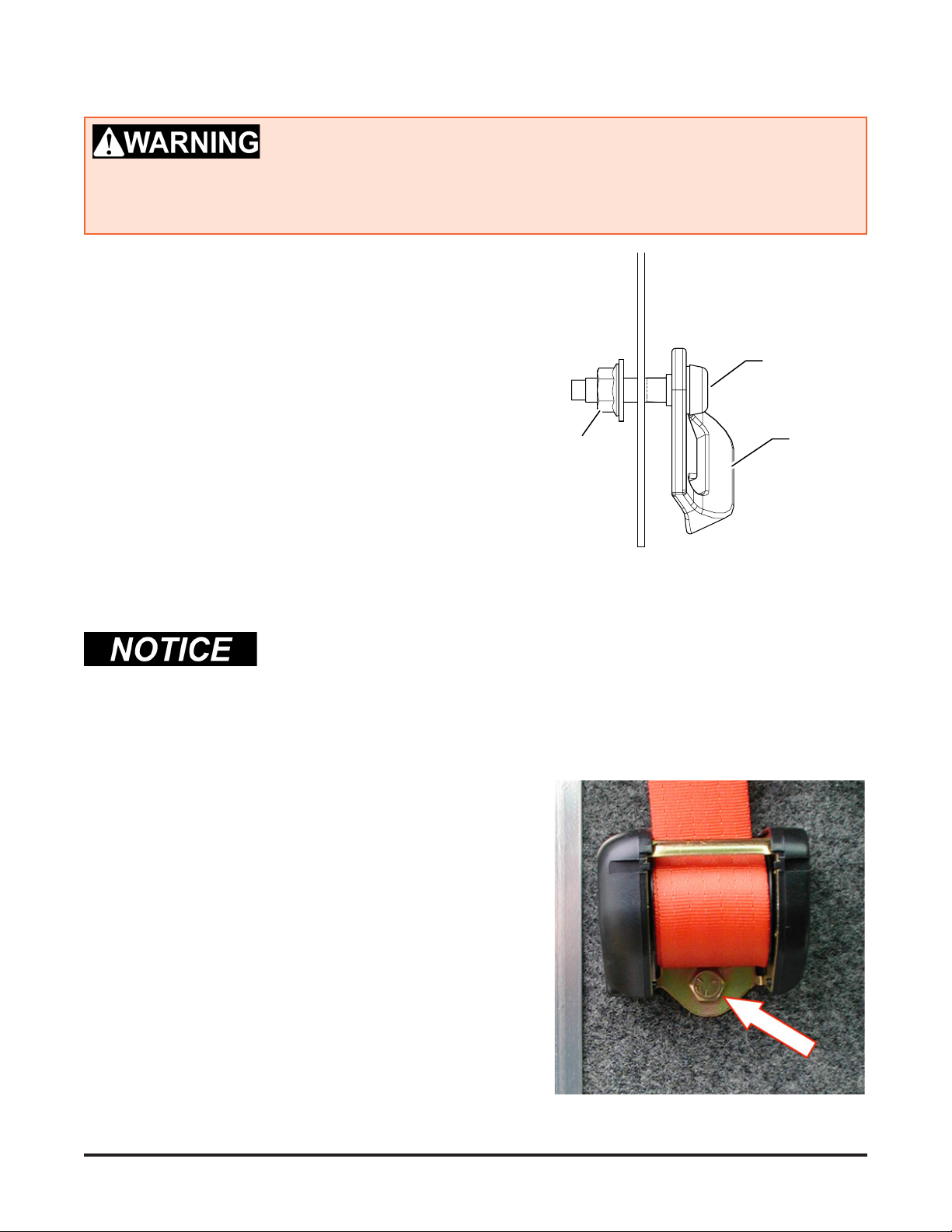

Retractor System

The retractor, the heart of the occupant restraint system, contains a locking mechanism and serves as a

storage device for the webbing when not in use. Check the retractor web storage device operation to

ensure that it is not locked up. The seat belt webbing

must spool out freely and retract properly.

An ELR (Emergency Locking Retractor) belt system

is sensitive to sudden decelerations of the vehicle.

An ALR (Automatic Locking Retractor) system

is sensitive to sudden pulls on the belt. If it locks,

release the belt, let it retract, and slowly pull it out

again.

Seat Belt Buckle

Check the buckle for proper operation by inserting the

latch and listening for an audible click. Verify that the

buckle is not damaged and that the plastic casing is not

broken or cracked. Examine the seat belt buckle cable

strap to determine if there is unusual wear, if the cable

is damaged, or if the cable is cut or frayed.

Buckle Latch Plate

Check the buckle latch plate for excessive wear. Make

sure the buckle latch is neither bent nor deformed. It

must latch properly into the buckle. Webbing or Latch Plate Wear

WEBBING (CUT, FRAYED,

OR WORN AT LATCH AREA)

BUCKLE LATCH

PLATE

Belts must be inspected during every routine maintenance. Failure to

properly inspect and maintain the seat belts can cause serious injury or

loss of life. The seat belt in a delivery vehicle application has a nite life

and must be replaced as needed throughout the life of the vehicle.

Whenever a vehicle is involved in an accident, the entire seat belt system

must be evaluated for replacement, even if there is no visible wear or

damage to the seat belt system.