Replace fuse/lamp only with the same type.

In the event of serious operating problem, stop using the unit immediately.

Never turn on and off the unit time after time.

The housing, the lenses, or the ultraviolet filter must be replaced if they are

visibly damaged.

DO NOT attempt to operate this unit if it becomes damaged. DO NOT attempt

any repairs

yourself. Repairs carried out by unskilled people can lead to damage or

malfunction. Please contact the nearest authorized technical assistance center

if needed.

Disconnect this product from its power source before servicing.

DO use the original packaging if the device is to be transported.

Avoid direct eye exposure to the light source while the product is on.

Never touch bulb with bare fingers, as it is very hot after using.

DO NOT operate this product if you see damage on the housing, shields, or

cables. Have the damaged parts replaced by an authorized technician at once

Installation:

The fixture should be fixed on the clamp. Always ensure that the unit is firmly

fixed to avoid vibration and slipping off during operation. Ensure that the

trussing or area of installation must be able to hold 10 times the weight without

any deformation. Always install a safety cable that can hold at least 12 times

the weight of the fixture when installing.DO install and operate by qualified

operator. It must be installed in a place where there is out of the reach of

people.

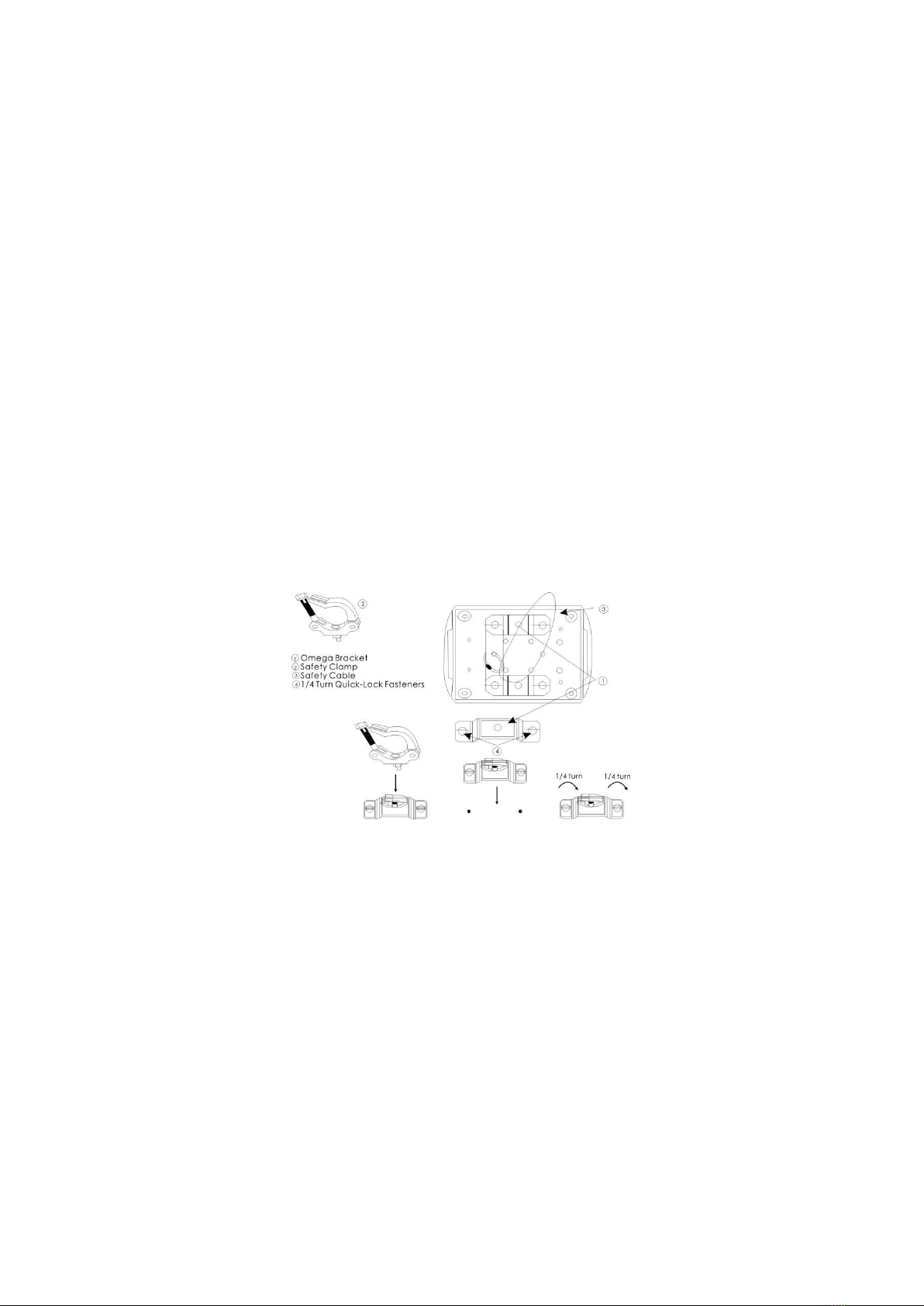

2.INSTALLATIONS

installations Note: In order to increase protection, please install the lamp on

the sidewalk, outside the seating area, or an area where unauthorized persons

may touch the lamp

Before installing the fixture on any surface, make sure that the installation area

can bear the minimum point load above 10 points of the weight of the

equipment. The installation of the fixing device must always be fixed with

auxiliary safety accessories (such as a suitable safety rope)

Do not stand directly under the equipment when installing, removing, or

servicing fixtures

From the ceiling or set on a flat surface (see the picture below). Ensure that

this fixture is kept at least 0.5m (1.5 feet) away from any flammable materials

(decorations, etc.)

Be sure to use and install the supplied safety rope to ensure safety and