8.Product parameter introduction

Input voltage: AC100-240V 50-60HZ

Output Voltage: V1:36V(Master board+LED driver), V2:12V(cooling fan+Display)

Power supply: 250W

Light source: 198W module high output white light LED

Light strip: 30pcs 0.5W RGB5050LED

Service life: 50,000 hours service life, low power consumption

Color temperature: 7500K

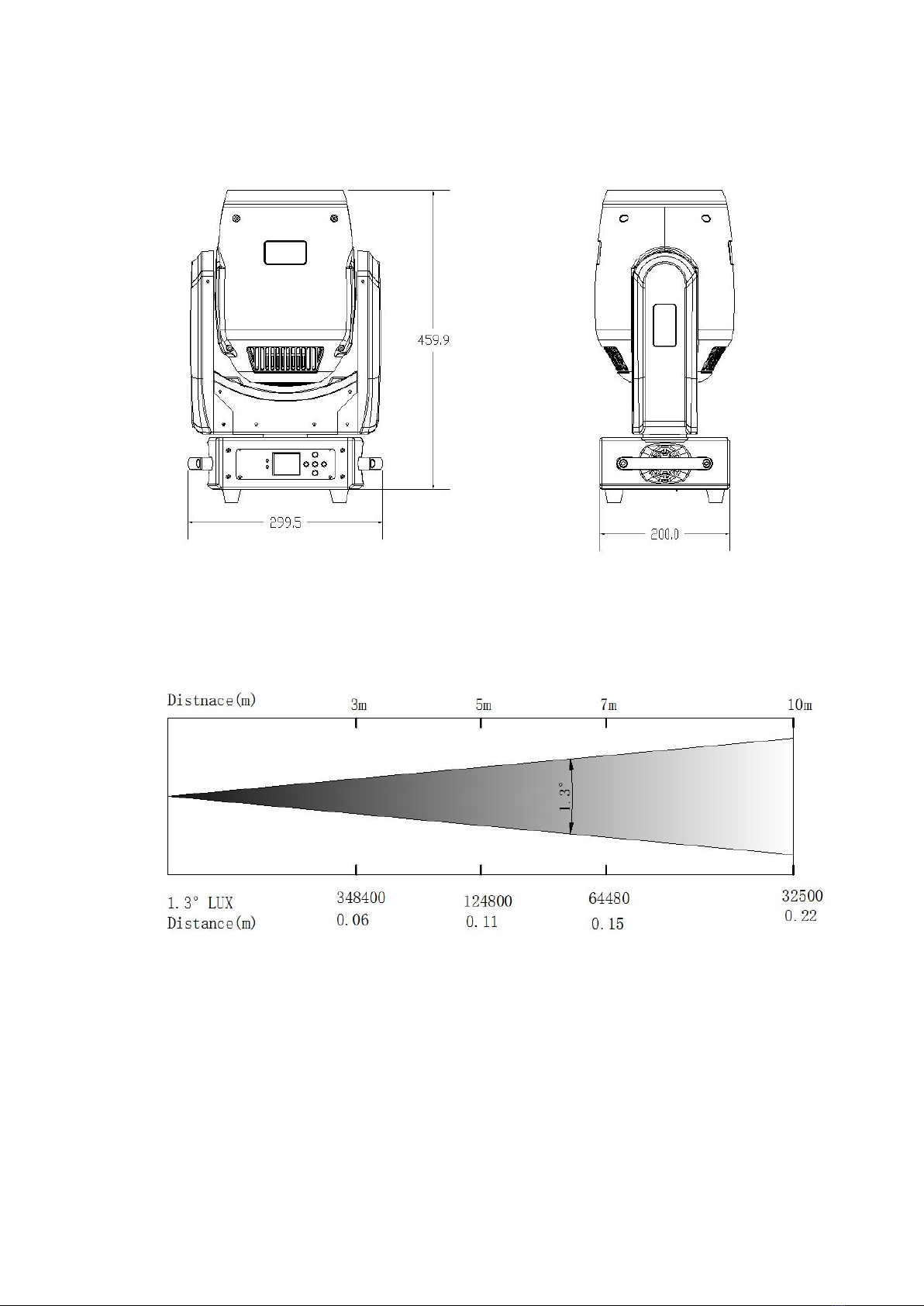

Beam angle: 1.3° beam angle, focusing function

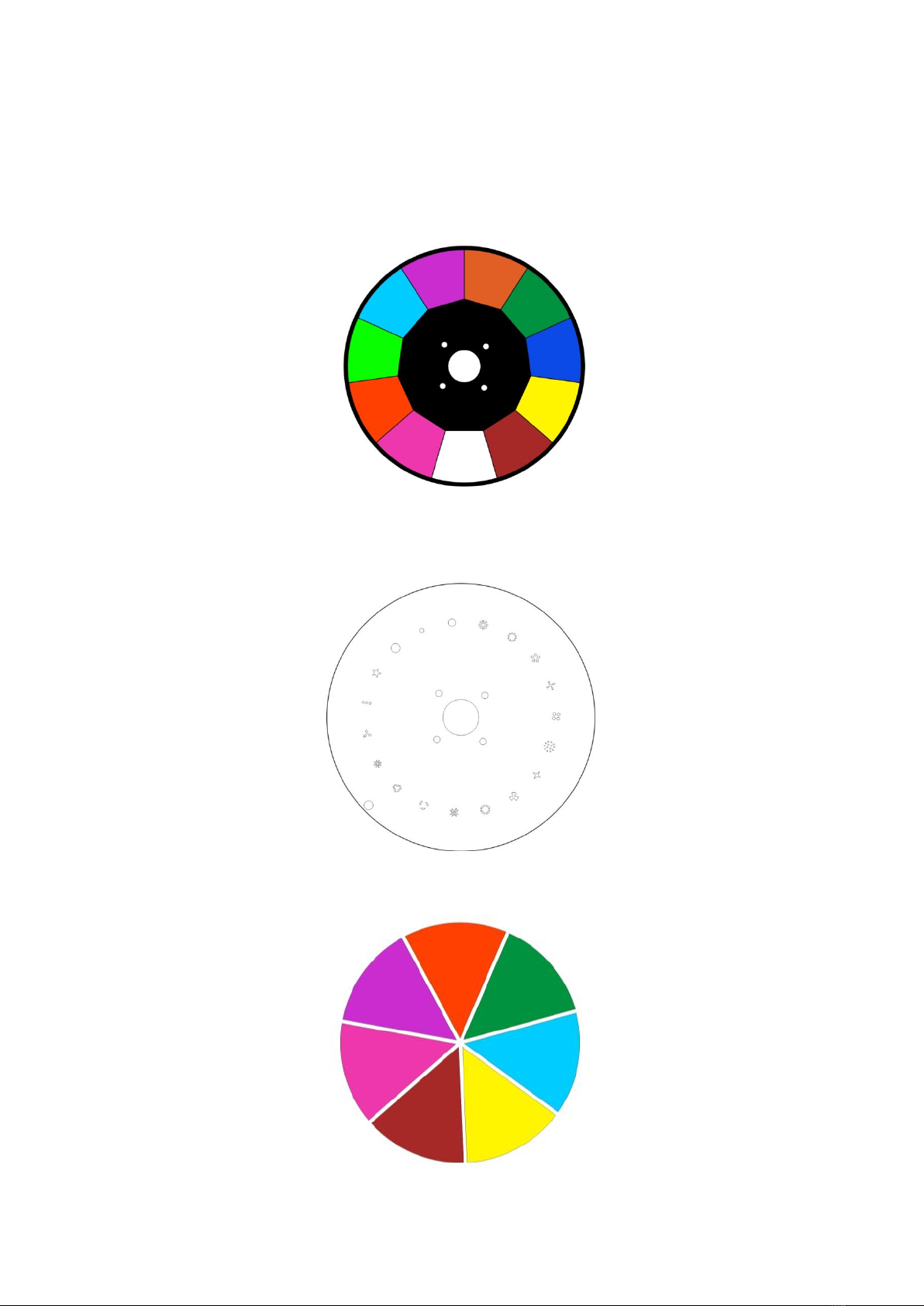

Color: 10 colors + white, variable direction and speed

Fixed gobos: 18 fixed gobos + white light, rotation and jitter

Prism: 16 prism, variable speed bidirectional rotation

With fog and colorful function

Strobe: high-speed strobe effect, 1-25 flashes per second

Channel: 17 CH

Control mode: DMX 512, master-slave, voice control, self-propelled

With remote RDM function

Auto focus function

Display mode: color liquid crystal display

Horizontal scan: 540 degrees (160bit precision scan) electronic error correction.

Vertical scanning: 270 degrees (160bit precision scanning) electronic error correction.

Temperature protection function, when the internal temperature reaches 40℃, the fan

starts to work, when the internal temperature reaches 70℃and the brightness is reduced

by half.

Features:

The appearance of the product is simple and exquisite, light weight, suitable for use in

multiple places, using high-brightness LED module light source, the light is sharp and the

spot is clear, using a two-in-one high-precision lens, the minimum light-emitting angle

reaches 1.3 degrees, a variety of stroboscopic effects, equipped with Atomization and

colorful functions, high standard constant current solution, strong uniformity of low

brightness, stable linear dimming, auto focus function, support RMD remote dialing

function, the light strip is equipped with 20 static effects and 51 dynamic effects. When

dialing the address code, press the up button in the menu to automatically increase the

number of channels, without calculating the address code of the next lamp, the lamp

automatically monitors the photocoupler and Hall data function, and has a temperature

self-check function, the lamp temperature reaches 40 degrees, the fan starts, The power

is reduced to 70 degrees to protect the life of the lamp beads.