shaft synchronization application vacon • 3

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Vacon shaft synchronization application manual

INDEX Document code: ud01115B

Date: 26.10.2006

1. Introduction ....................................................................................................................... 5

1.1 Requirements ............................................................................................................................. 6

1.2 Trial Time period......................................................................................................................... 6

2. Control I/O ......................................................................................................................... 7

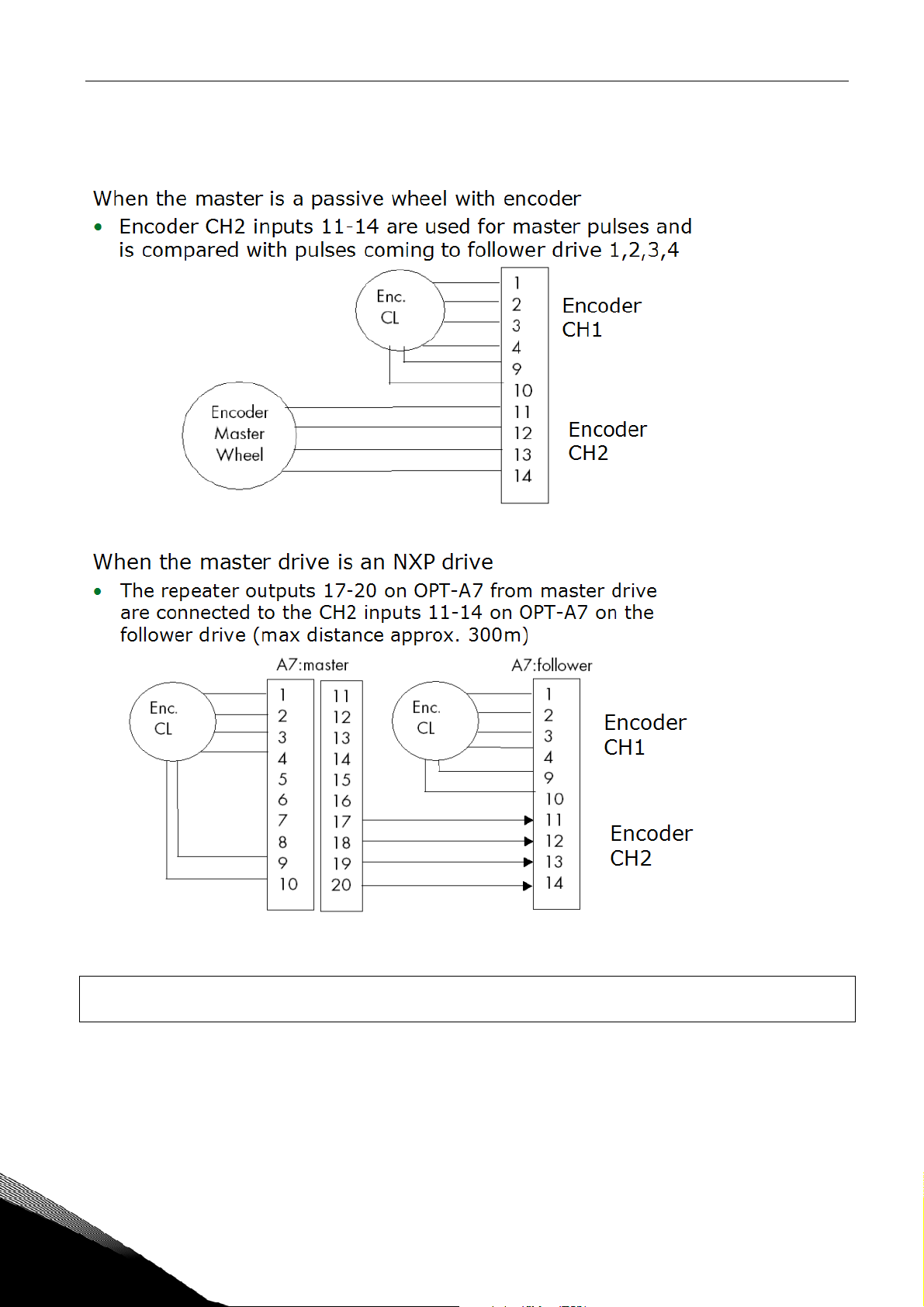

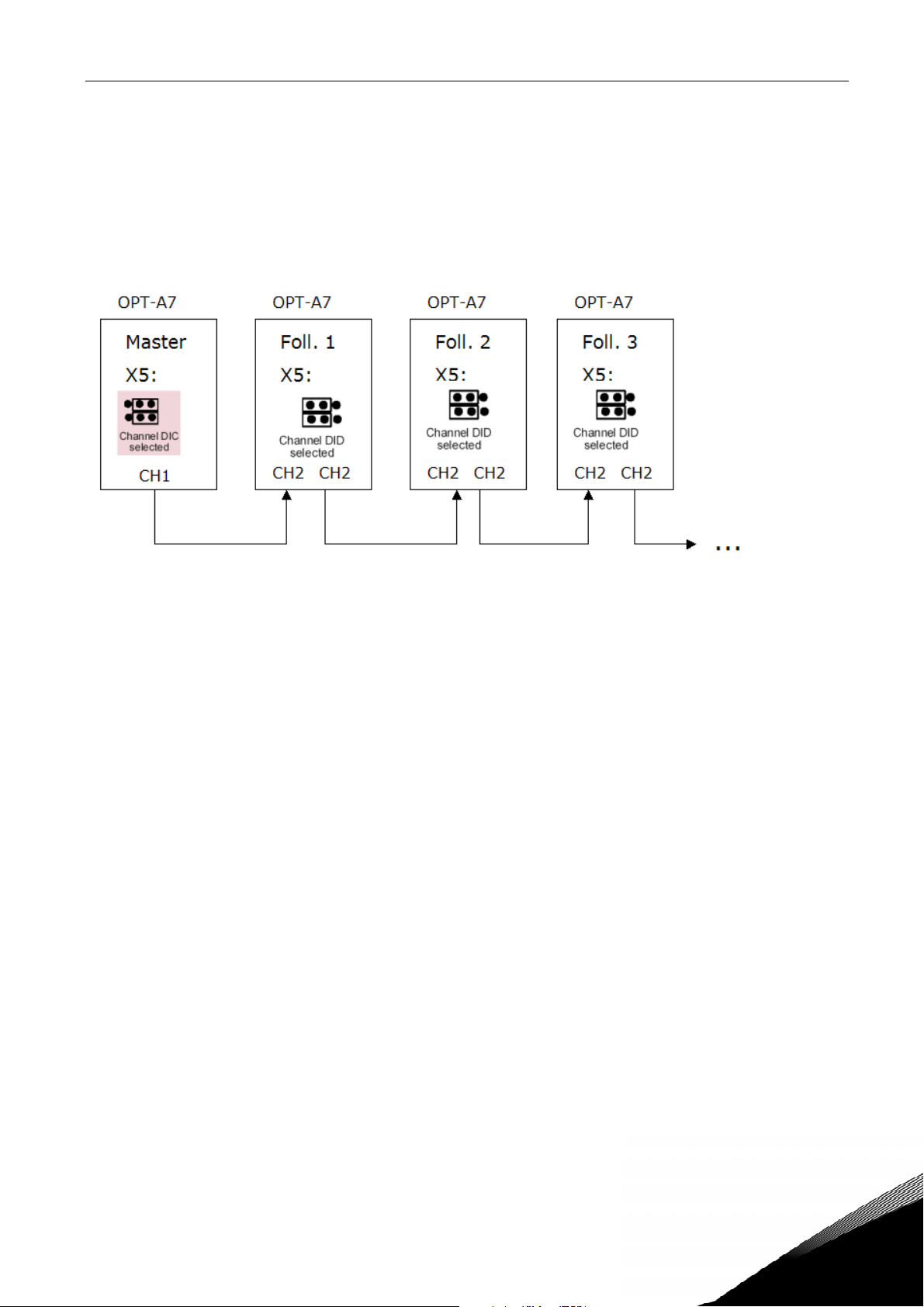

3. Connection of signals between master and follower drive (OPT-A7) ................................. 8

4. Jumper setting on the OPT-A7 board................................................................................. 9

5. “Terminal To Function” (TTF) programming principle ..................................................... 10

5.1 Defining an input/output for a certain function on keypad ..................................................... 10

5.2 Defining a terminal for a certain function with NCDrive programming tool.......................... 11

5.3 Defining unused inputs/outputs............................................................................................... 12

6. Shaft Synchronization Application – Parameter lists....................................................... 13

6.1 Monitoring values (Control keypad: menu M1)........................................................................ 13

6.2 Basic parameters (Control keypad: Menu M2 G2.1) ........................................................... 14

6.3 Input signals.............................................................................................................................. 15

6.3.1 Basic settings (Control keypad: Menu M2 G2.2.1) .................................................... 15

6.3.2 Analogue input 1 (Control keypad: Menu M2 G2.2.2)................................................ 15

6.3.3 Analogue input 2 (Control keypad: Menu M2 G2.2.3)................................................ 16

6.3.4 Free analogue input, signal selection (Keypad: Menu M2 G2.2.4) ........................... 16

6.3.5 Digital inputs (Control keypad: Menu M2 G2.2.5)...................................................... 17

6.4 Output signals........................................................................................................................... 18

6.4.1 Delayed digital output 1 (Keypad: Menu M2 G2.3.1) ................................................. 18

6.4.2 Delayed digital output 2 (Keypad: Menu M2 G2.3.2) ................................................. 18

6.4.3 Digital output signals (Control keypad: Menu M2 G2.3.3) ........................................ 19

6.4.4 Limit settings (Control keypad: Menu M2 G2.3.4)..................................................... 20

6.4.5 Analogue output 1 (Control keypad: Menu M2 G2.3.5) ............................................. 21

6.4.6 Analogue output 2 (Control keypad: Menu M2 G2.3.6) ............................................. 21

6.4.7 Analogue output 3 (Control keypad: Menu M2 G2.3.7) ............................................. 22

6.4.8 Mechanical Brake (Control keypad: Menu M2 G2.3.8).............................................. 22

6.5 Drive control parameters (Control keypad: Menu M2 G2.4)............................................... 23

6.6 Motor control parameters (Control keypad: Menu M2 G2.5).............................................. 24

6.6.1 PMSM settings (Control keypad: Menu M2 G2.5.19)................................................. 25

6.7 Protections (Control keypad: Menu M2 G2.6)...................................................................... 26

6.8 Fieldbus parameters (Control Keypad: Menu M2 G2.7) ...................................................... 28

6.9 Torque control parameters (Control Keypad: Menu M2 G2.8) ............................................ 29

6.10 Shaft synchronization parameters (Control keypad: Menu M2 G2.9) ................................ 30

6.11 License key (Control keypad: Menu M2 G2.10) ................................................................... 31

6.12 Keypad control (Control keypad: Menu M3)............................................................................. 31

6.12.1 System menu (Control keypad: Menu M6)................................................................. 31

6.12.2 Expander boards (Control keypad: Menu M7) ........................................................... 31

7. Description of parameters ............................................................................................... 32

7.1 Keypad control parameters...................................................................................................... 85