CONTENTS

1. PREFACE....................................................................................... 2

1.1 General ........................................................................................................2

1.2 Symbols .......................................................................................................3

1.3 Copyright .....................................................................................................3

2. SYSTEM DESCRIPTION................................................................ 4

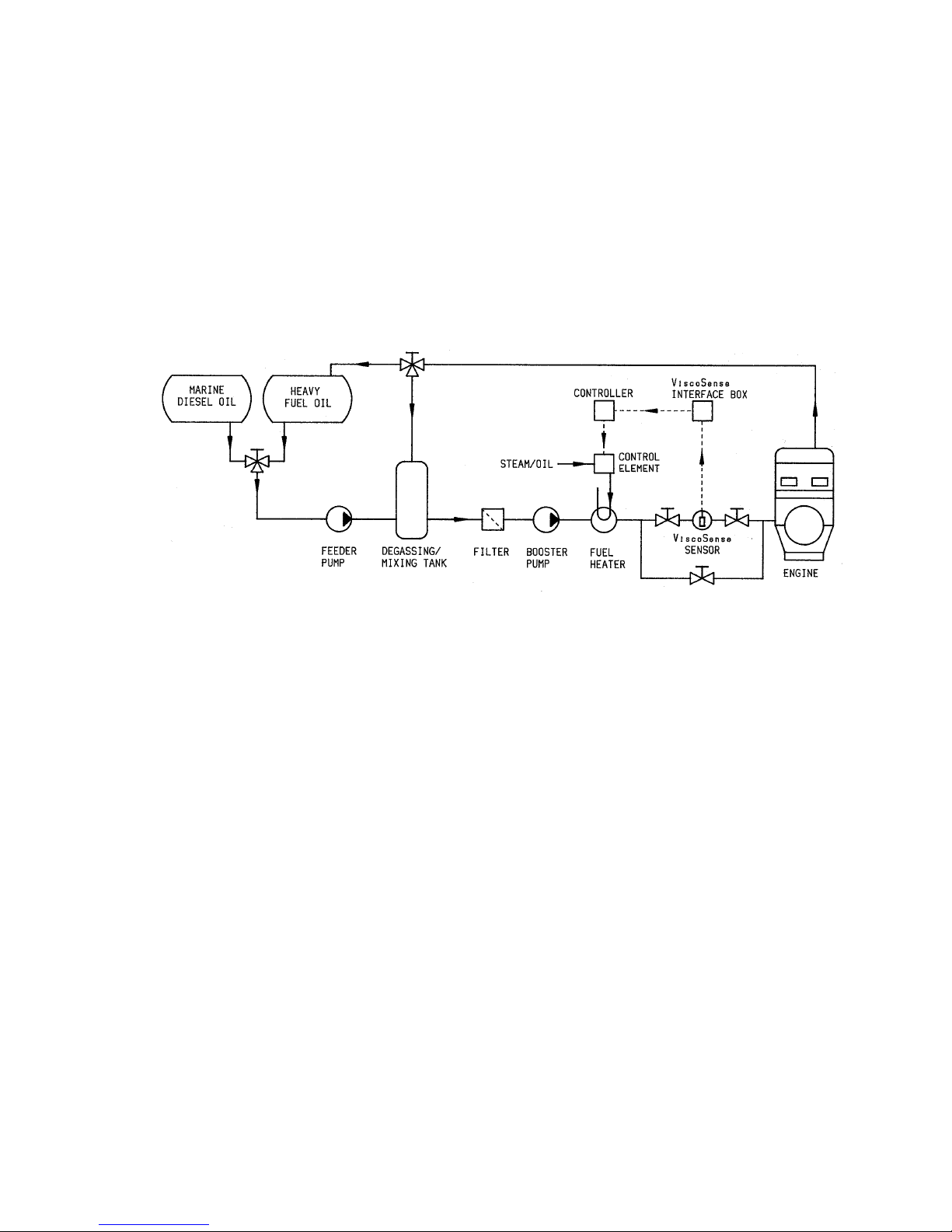

2.1 System description.......................................................................................4

2.2 System components ....................................................................................5

2.3 Principle of operation ...................................................................................6

3. TECHNICAL SPECIFICATION ....................................................... 7

3.1 Sensor .........................................................................................................7

3.2 Sensor housing............................................................................................7

3.3 Interface box ................................................................................................8

4. SAFETY INSTRUCTIONS .............................................................. 8

4.1 Safety precautions .......................................................................................8

5. UNPACKING .................................................................................. 9

6. INSTALLATION .............................................................................. 9

6.1 To record nameplate data............................................................................9

6.2 Conditions for correct working of the ViscoSense®3 sensor ......................10

6.3 General installation recommendations.......................................................11

6.4 Mechanical installation...............................................................................11

6.4.1 ViscoSense®3interface box..............................................................11

6.4.2 ViscoSense®3 housing......................................................................11

6.4.3 To assemble ViscoSense®3 sensor ..................................................13

6.5 Electrical installation ..................................................................................15

6.6 Connection of sensor to interface box........................................................16

6.7 Installation checklist version 1.0.................................................................17

7. OPERATING INSTRUCTIONS..................................................... 19

7.1 Initial start-up .............................................................................................19

7.2 Shut-down on heavy fuel oil.......................................................................19

7.3 Shut-down on diesel oil..............................................................................19

7.4 Routine start-up .........................................................................................19

8. MAINTENANCE............................................................................ 20

8.1 Routine maintenance .................................................................................20

8.2 To clean the ViscoSense®3 sensor............................................................20

8.2.1 General procedure ............................................................................20

9. REPAIR OR REPLACEMENT ...................................................... 21

9.1 Repair ........................................................................................................21

9.2 Replacement..............................................................................................21

9.3 Procedure for using the micro SD card ......................................................21

10. TAKE OUT OF SERVICE ......................................................... 22

11. REMOVAL AND STORAGE OF EQUIPMENT......................... 23

12. MALFUNCTION AND SEND FOR REPAIR ............................. 23