Table of contents

1. About this document.....................................................................................5

1.1 Version information.......................................................................................... 5

1.2 Related manuals................................................................................................5

1.3 Documentation conventions........................................................................... 6

1.4 Trademarks........................................................................................................ 6

2. Product overview............................................................................................ 7

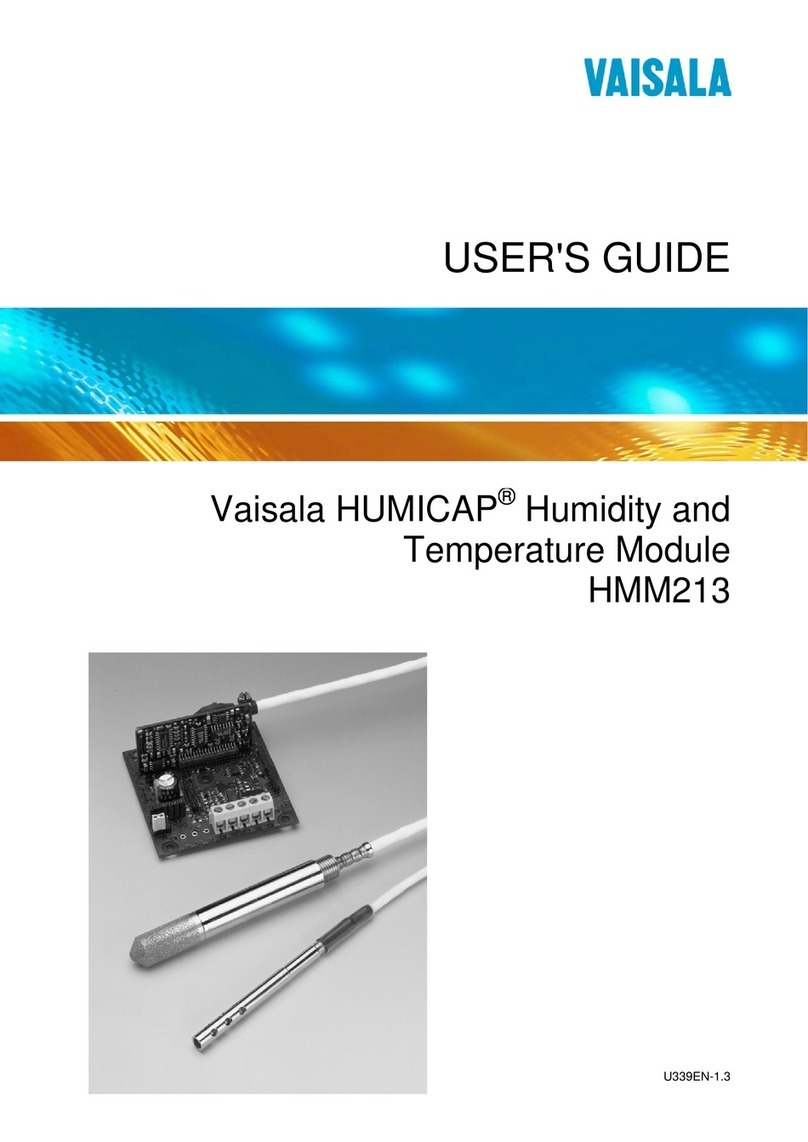

2.1 Introduction to HMM170...................................................................................7

2.2 Basic features and options...............................................................................7

2.3 Sensor types...................................................................................................... 8

2.4 Output parameters........................................................................................... 9

2.5 Probe head.......................................................................................................10

2.6 Filter types....................................................................................................... 10

2.7 LED indicator.....................................................................................................11

2.8 Safety................................................................................................................ 12

2.8.1 ESD protection..........................................................................................12

3. Functional description.................................................................................13

3.1 HUMICAP technology..................................................................................... 13

3.2 Chemical purge................................................................................................13

3.3 Condensation prevention functions..............................................................14

4. Installation........................................................................................................ 16

4.1 Installing module............................................................................................. 16

4.2 Selecting probe mounting location and method.........................................17

4.3 Installing probe................................................................................................ 18

5. Operation.......................................................................................................... 19

5.1 Using service port............................................................................................19

5.1.1 Installing driver for the USB service cable............................................ 19

5.2 Modbus............................................................................................................20

5.3 Vaisala Insight software.................................................................................20

5.3.1 Connecting to Insight software.............................................................20

5.3.2 Configuration options..............................................................................21

5.3.3 Configuring condensation prevention................................................... 21

6. Maintenance....................................................................................................22

6.1 Cleaning probe................................................................................................22

6.2 Cleaning HUMICAP 180L2 sensor................................................................. 22

6.3 Replacing filter................................................................................................23

6.4 Calibration and adjustment...........................................................................23

6.4.1 Adjustment points and requirements...................................................24

6.4.2 Adjusting measurement with Insight software................................... 25

7. Technical data................................................................................................ 26

7.1 HMM170 specifications...................................................................................26

Table of contents

1