Compa II series Table of contents

07.15 Operating manual 3

Table of contents

Table of contents.............................................................................. 3

1Important notes ..................................................................... 5

1.1Intended use............................................................................ 5

1.2Environmentally-friendly disposal............................................ 6

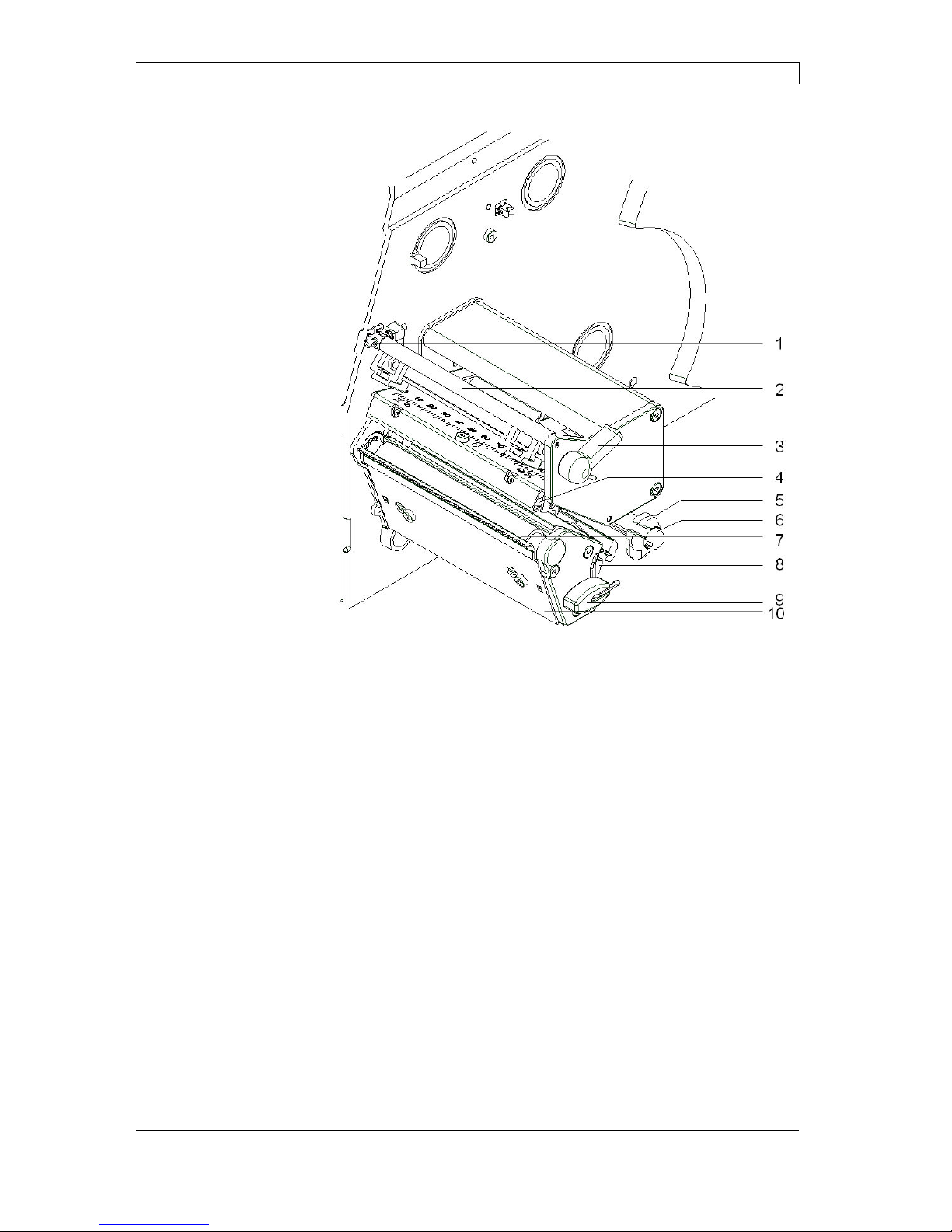

1.3Assembly drawings.................................................................. 6

2Safety notes ........................................................................... 9

2.1Warnings ................................................................................. 9

2.2Operating conditions.............................................................. 10

3Technical data...................................................................... 15

3.1Control inputs and outputs .................................................... 18

3.2Plug & Play ............................................................................ 23

4Installation............................................................................ 25

4.1Setting up the label printer .................................................... 25

4.2Connecting the label printer .................................................. 26

4.3Switching the label printer on and off .................................... 26

4.4Initiation of the label printer ................................................... 27

5Loading media ..................................................................... 29

5.1Loading label roll ................................................................... 29

5.2Removing wound roll............................................................. 35

5.3Loading fanfold labels ........................................................... 36

5.4Loading transfer ribbon ......................................................... 37

5.5Setting feed path of transfer ribbon....................................... 38

5.6Removing and/or installing rewind guide plate...................... 39

6Function menu..................................................................... 41

6.1Operation panel ..................................................................... 41

6.2Menu structure....................................................................... 42

6.3Print settings.......................................................................... 46

6.4Label layout ........................................................................... 47

6.5Device settings ...................................................................... 49

6.6Network ................................................................................. 52

6.7Remote console..................................................................... 52

6.8Interface................................................................................. 53

6.9Emulation............................................................................... 54

6.10Date & Time........................................................................... 55

6.11Service functions ................................................................... 56

6.12Main menu............................................................................. 58

7Options ................................................................................. 59

7.1Cutter..................................................................................... 59

7.2Dispenser I/O......................................................................... 61

7.3Label applicator ..................................................................... 65

7.4WLAN .................................................................................... 69

8Compact Flash Card / USB Memory Stick ........................ 71

8.1General Information............................................................... 71

8.2Display Structure ................................................................... 71

8.3Navigation.............................................................................. 72

8.4Define User Directory ............................................................ 73

8.5Load Layout........................................................................... 74

8.6File Explorer .......................................................................... 75

8.7Firmware Update ................................................................... 80

8.8Filter....................................................................................... 80