Table of contents

1

PRINTER DRIVER INSTALLATION .......................................................................................1

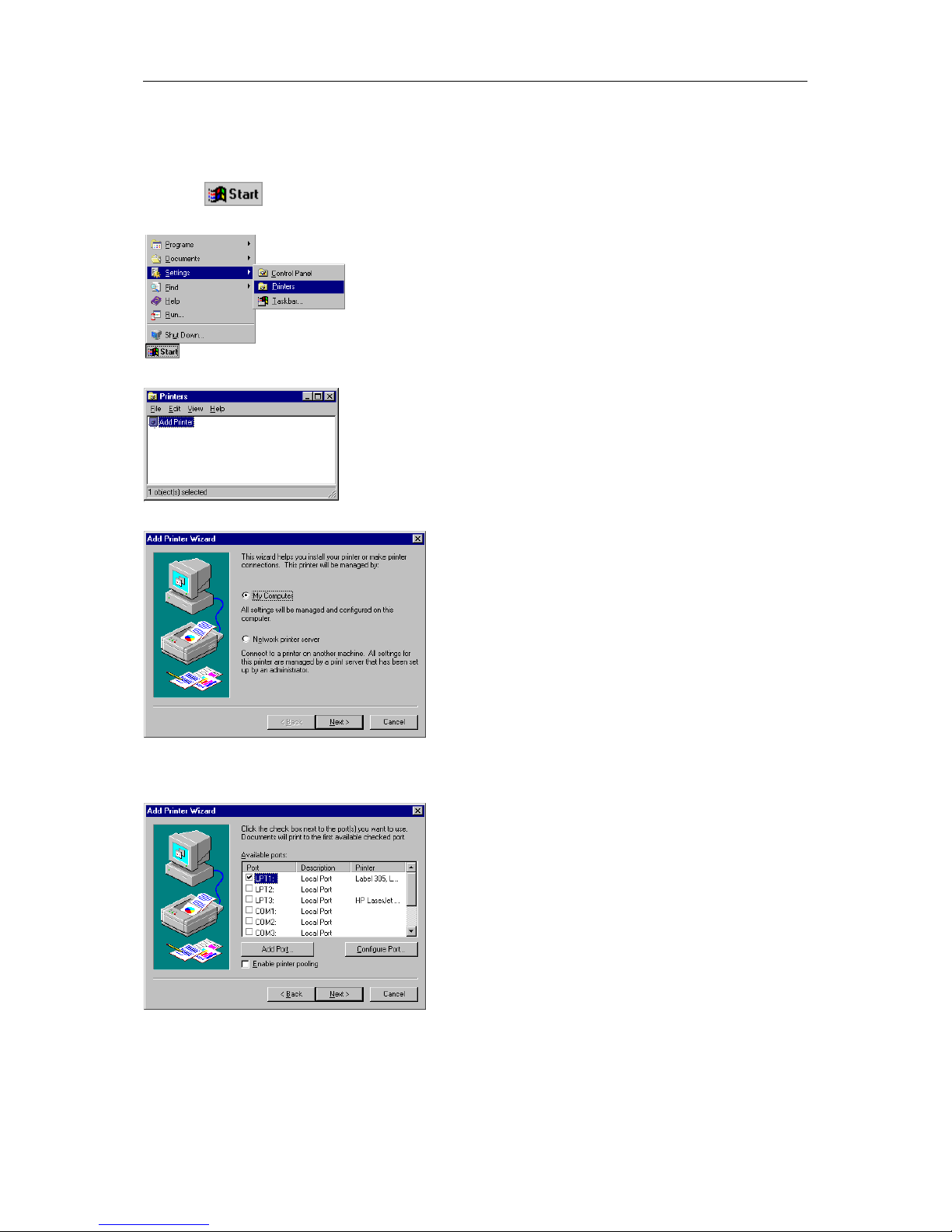

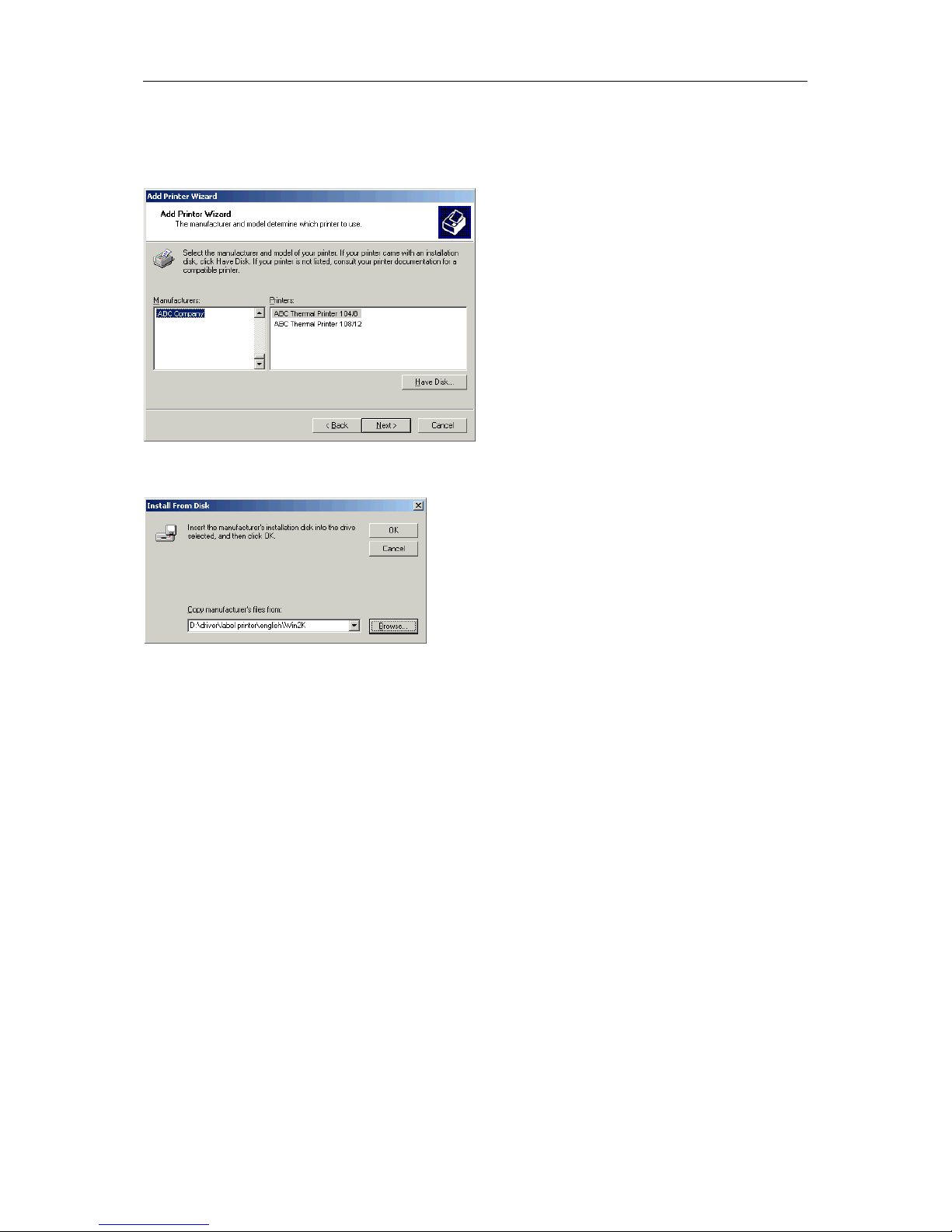

Windows 95, Windows 98 and Windows Me ...........................................................................................................1

Windows NT ............................................................................................................................................................3

Windows 2000 Professional ....................................................................................................................................5

INITIAL OPERATION ..............................................................................................................7

INSTALLATION....................................................................................................................... 7

Printer rear...............................................................................................................................................................8

LOADING OF PRINT MATERIAL ........................................................................................... 9

Loading of labels in standard mode.........................................................................................................................9

Loading of labels in rewinding mode .....................................................................................................................10

Loading of labels in cutter mode............................................................................................................................12

Loading of labels in peel-off mode.........................................................................................................................13

Loading of fan-fold material ...................................................................................................................................14

Loading of transfer ribbon......................................................................................................................................15

TECHNICAL DATA ............................................................................................................... 16

TEAR-OFF ............................................................................................................................ 17

CLEANING OF CUTTER ...................................................................................................... 18

OPERATING AND DISPLAY ELEMENTS ............................................................................ 19

FUNCTIONS ......................................................................................................................... 20

Print .......................................................................................................................................................................20

Status print ............................................................................................................................................................20

Label feed..............................................................................................................................................................20

Saving ...................................................................................................................................................................20

REWINDING UNIT PR28 ...................................................................................................... 21