Table of Contents

1Introduction............................................................................ 5

1.1 General Instructions ................................................................ 5

1.2 Intended Use........................................................................... 6

1.3 Safety Instructions................................................................... 6

2Product Description.............................................................. 9

2.1 Product Designation................................................................ 9

2.2 Function................................................................................... 9

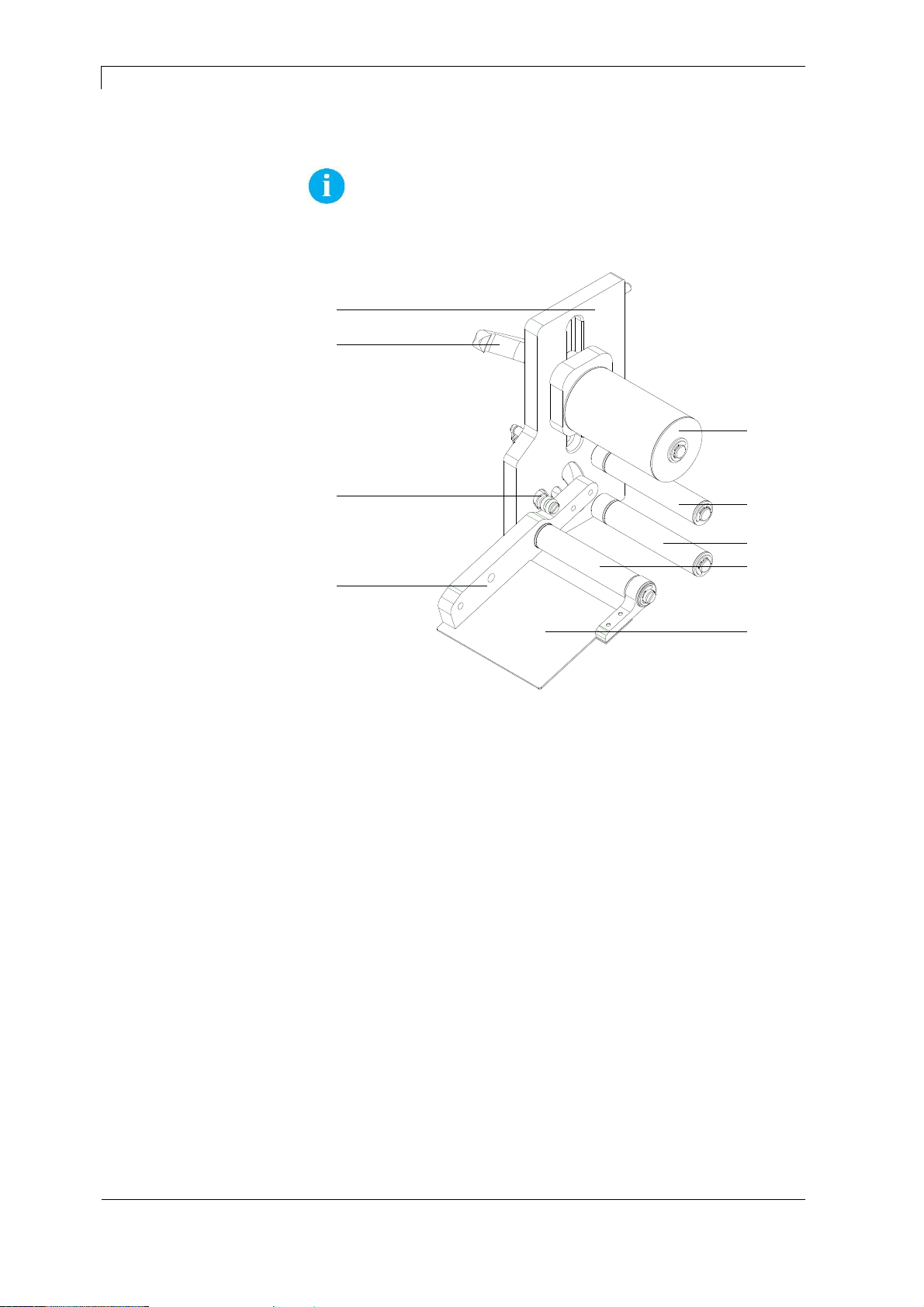

2.3 Overview................................................................................ 10

3Technical Data..................................................................... 11

4Installation............................................................................ 13

4.1 Unpack the Wipe-On Applicator............................................ 13

4.2 Scope of Delivery .................................................................. 13

4.3 Connect the Transducer to Printing System ......................... 13

4.4 Connect the Wipe-On Applicator........................................... 14

4.5 Install the Pressure Roller (Optional) .................................... 15

4.6 Install the Pressur Brush (Optional) ...................................... 15

4.7 Insert the Label Material........................................................ 16

4.8 Adjust the Displacement Unit................................................ 17

5Adjustments......................................................................... 19

5.1 Adjust the Dispensing Angle ................................................. 19

5.2 Adjust the Pressur Roller (Optional)...................................... 21

5.3 Adjust the Pressure Brush (Optional).................................... 22

5.4 Adjust the Labelling Position................................................. 23

6Options................................................................................. 25

6.1 Product Sensor...................................................................... 25

7Environmentally-Friendly Disposal................................... 27

8Index ..................................................................................... 29