2.9 This fire is suitable for use against walls with combustible cladding. Please note, however, that soft wall coverings

(e.g. embossed vinyls etc.) are easily affected by heat. They may, therefore, scorch or become discoloured when close to a

heating appliance. Please bear this in mind when installing.

2.10 A minimum clearance of 100mm must be maintained from the side panels of the fire on all installations to allow

consumer access for removal of the outer case. Any combustible side wall must be at least 500mm clear of direct exposure

to the radiant surface of the appliance unless suitably protected.

2.11 A minimum clearance of 150mm must be maintained above

the appliance for access to the control.

2.12 A combustible shelf may be fitted over the appliance provided

that the following conditions are satisfied:-

(a) In the case of a shelf not more than 150mm deep, there is at least

150mm clearance above the extreme top surface of the fire.

(b) For a shelf of greater depth there is an additional clearance of

12.5mm for each extra 25mm of added shelf depth.

2.13 The flue spigot and any spigot extension must be capable of

passing through the closure plate by a least 25mm with a minimum

clearance of 50mm between its open end and the nearest obstruction.

There must also be a minimum clearance of 165mm between the back

of the closure plate and the back of the catchment spare (Fig.2). The

catchment space below the flue spigot must extend at least 250mm

downwards measured from the bottom of the flue spigot (Fig.2).

3. UNPACKING

The carton contains the following:-

1Fire assembly

1Closure plate

1Flue spigot

1Coal bed

1Pack of fixing screws

Remove all the items carefully to prevent damage. Some items may be

contained in the packaging fitments - Examine the packaging carefully

before discarding. Check that all the items are present and undamaged.

4. FIT THE CLOSURE PLATE

4.1 Hearth Mounting

The closure plate (Fig.3) must be fitted and sealed to the

hearth and fireplace surround using a suitable heat resistant

material.

4.1.1 Cut straight across the top of the plate when trimming

to the correct height. Cut off the top and sides of the closure

plate to overlap the fireplace opening by 25mm.

4.1.2 Seal the closure plate to the wall using a suitable heat

resisting material. The air relief opening at the bottom of the

closure plate must be clear and not covered by tape.

4.2 Wall Mounting

When wall mounting, the bottom of the fire and closure plate

must be at least 100mm above any carpet or other

combustible floor covering.

4.2.1 Using the closure plate as a template, hold the plate

over the fireplace opening and mark the positions of the four

wall fixing holes (see Fig.3)

4.2.2 Remove the plate. Drill and plug the wall at the

fixing positions.

4.2.3 If necessary, cut off the top of the closure plate so that

the overlap above the fireplace opening is 25mm.

4.2.4 If the bottom edge of the closure plate is below the

bottom edge of the fireplace opening, cut out an air relief

opening at the bottom to give a free opening of 56mm wide

and 32mm high.

4.2.5 Seal the closure plate to the wall using a suitable heat

resisting material. The air relief opening at the bottom of the

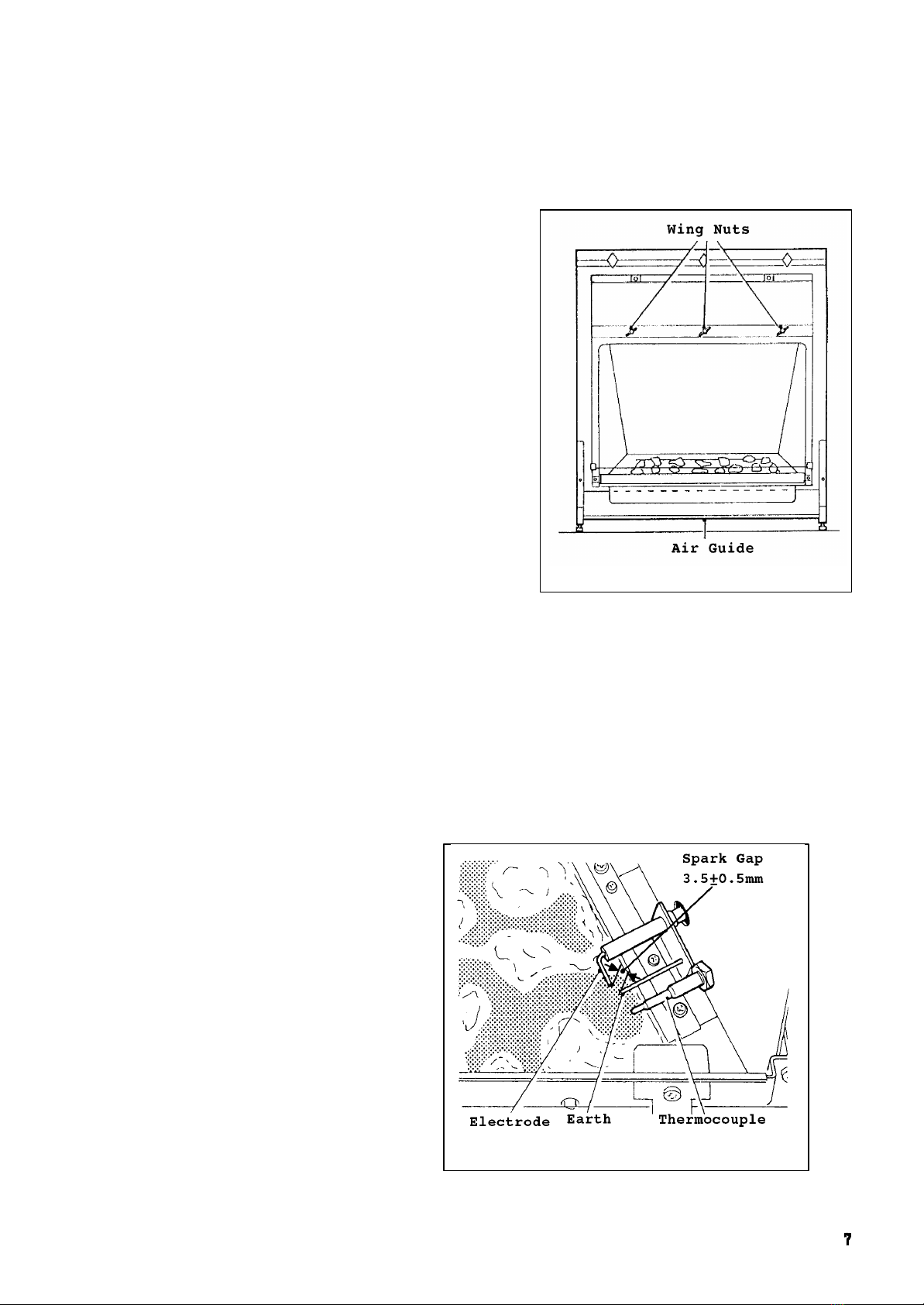

Fig. 2 Catchment Space

Fig. 3 Closure Plate