4IOM-3600

V. MAINTENANCE

Tank or system protection is the primary function

of the weight loaded Vacuum Relief Vent. As a

safety device, it is very important that maintenance/

inspection be done on a regular interval. Maintenance

should only be done by a qualified technician. Valve

Concepts recommends that all service be performed

at the factory or a factory authorized repair center.

For information on repair centers in your area,

please contact factory.

Maintenance procedures hereinafter are based

upon removal of the relief vent unit from the tank

where installed.

Owner should refer to Owner’s procedures for re-

moval, handling and cleaning of nonreusable parts,

i.e. gaskets, suitable solvents, etc.

To Dis-assemble: Remove cap screws (10), cover

(8) and the TFE tape / rope seal (34).

Inspect cover for corrosion, damage, or product

build up. Clean with a suitable solvent, replace as

necessary.

NOTE: During re-assembly, install new TFE tape /

rope (34).

Remove pallet assembly, including any loading

weights (28) that may be on the pallet (26).

Clean and inspect pallet assembly. Inspect the

diaphragms (25) and replace if necessary.

To Replace Diaphragm: Secure stem assembly

(30) in a soft-jawed vise with short, threaded end up.

Remove washer and nut (14).

Lift up to remove diaphragm retainer (24) and

diaphragm (25). Clean stem assembly and

diaphragm retainer with a suitable solvent, replace

as necessary. NOTE: Before re-assembly, apply

TFE paste to threads of the stem and around center

hole on the pallet (26).

Install new diaphragm (25). Re-install diaphragm

retainer (24) and washer, secure nut (14) tight on

stem.

Inspect and clean seat ring (16). NOTE: FRP seat

surfaces are integral inside the body. Check seat

surface for any nicks, corrosion, pitting or product

build up. Seat surface must be clean and smooth for

vent to perform properly.

To Remove Seat Ring: Make a match mark between

the flange (1) and the upper body (13). Rotate cap

screws (15) CCW and remove. Remove guides (29).

(Use the slot on top of the guides and rotate CCW to

remove.) Mark the location of each guide on the seat

ring (16) flange for reference at re-assembly.

SECTION V

CAUTION

The pipeaway body (13) is no longer fastened securely

to the flange (1) and could fall and cause severe per-

sonal injury and material damage.

Lift up to remove seat ring (16) and TFE tape / rope

seal (34.1). Inspect guides (29) and inside of the

body cavity for any corrosion or product build up.

Clean all parts as necessary.

To Remove Pipeaway Tape Seals: Separate

pipeaway upper body (13) from flange (1). Remove

TFE tape seals (34.1 & 34.2) and clean sealing

surface of both parts. Place new TFE tape seals

(34.1 & 34.2) in grooves on flange (1) face. See

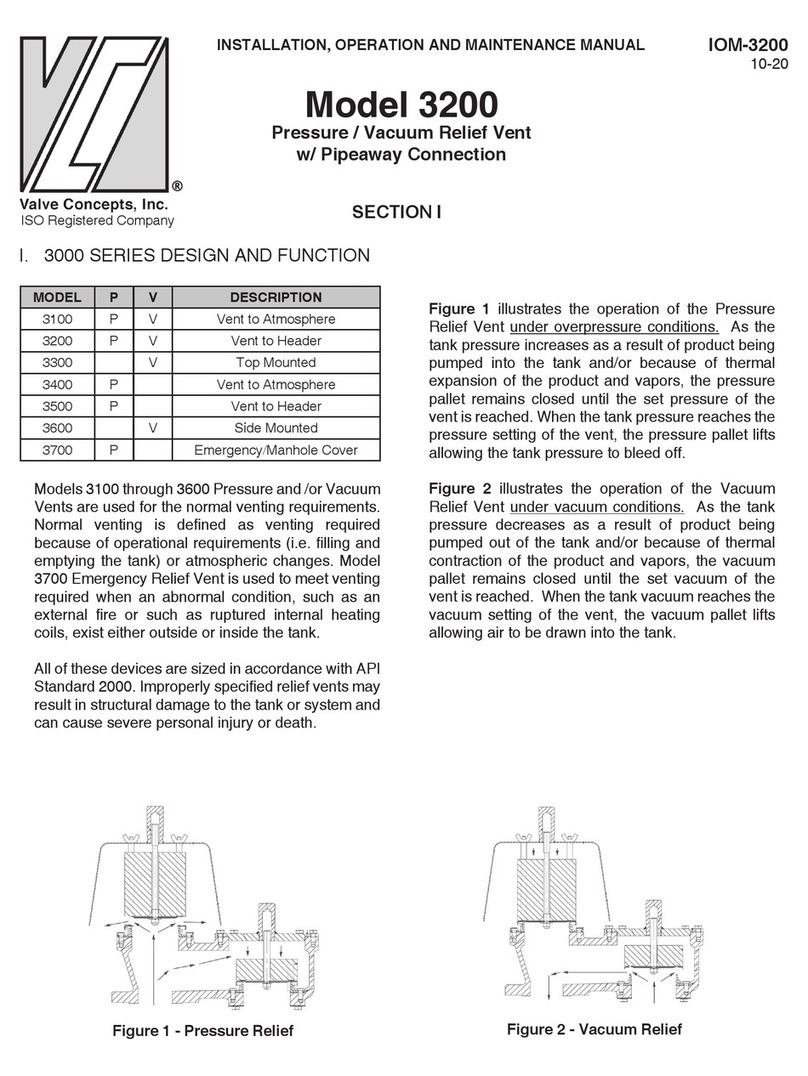

Figure 8.

Using match marks align upper body with flange

and lower pipeaway body on flange, resting on tape

seals.

Place new seat ring TFE tape seal (34.1) in groove

in upper body (13). See Figure 8

Using match marks align seat ring (16) with body

and re-position seat ring back in body, resting on

tape seal.

Re-install pallet guides (29) around the seat ring as

previously marked. Install cap screws (15) - apply

15 ft.-lbs. (20.3 Nm) torque to tighten.

Place pallet stem assembly on seat ring (16).