Arc protection unit

User manual

VAMP Ltd

4

VAMP 24h support phone : +358 (0)20 753 3264

VM120 EN001

1. General

This manual describes the general functions of the arc

protection unit, it also includes mounting and configuration

instructions.

1.1. Arc protection unit VAMP 120

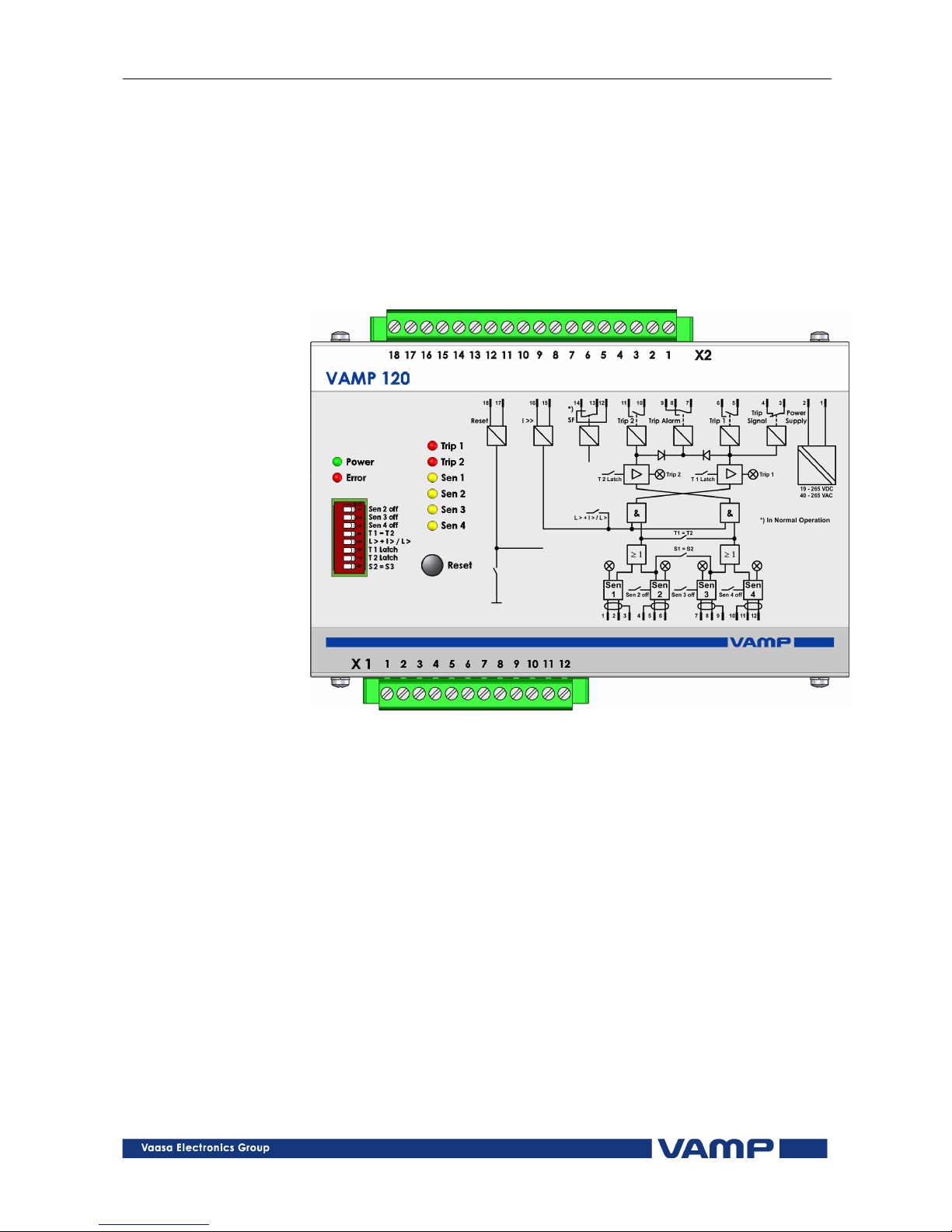

Figure 1.1-1. Arc protection unit VAMP 120

1.2. Unit features

VAMP 120 is a state of the art arc protection unit for electrical

po er distribution systems.

By using VAMP 120 in s itchgears considerable safety

improvements are obtained in the form of minimized injury and

damage in case of an arc fault.

VAMP 120 is a “stand alone” system, hich gives a compact

solution hen the application doesn’t require overcurrent

measurement or hen the overcurrent information is available

from the incomer protection relay or any other arc protection

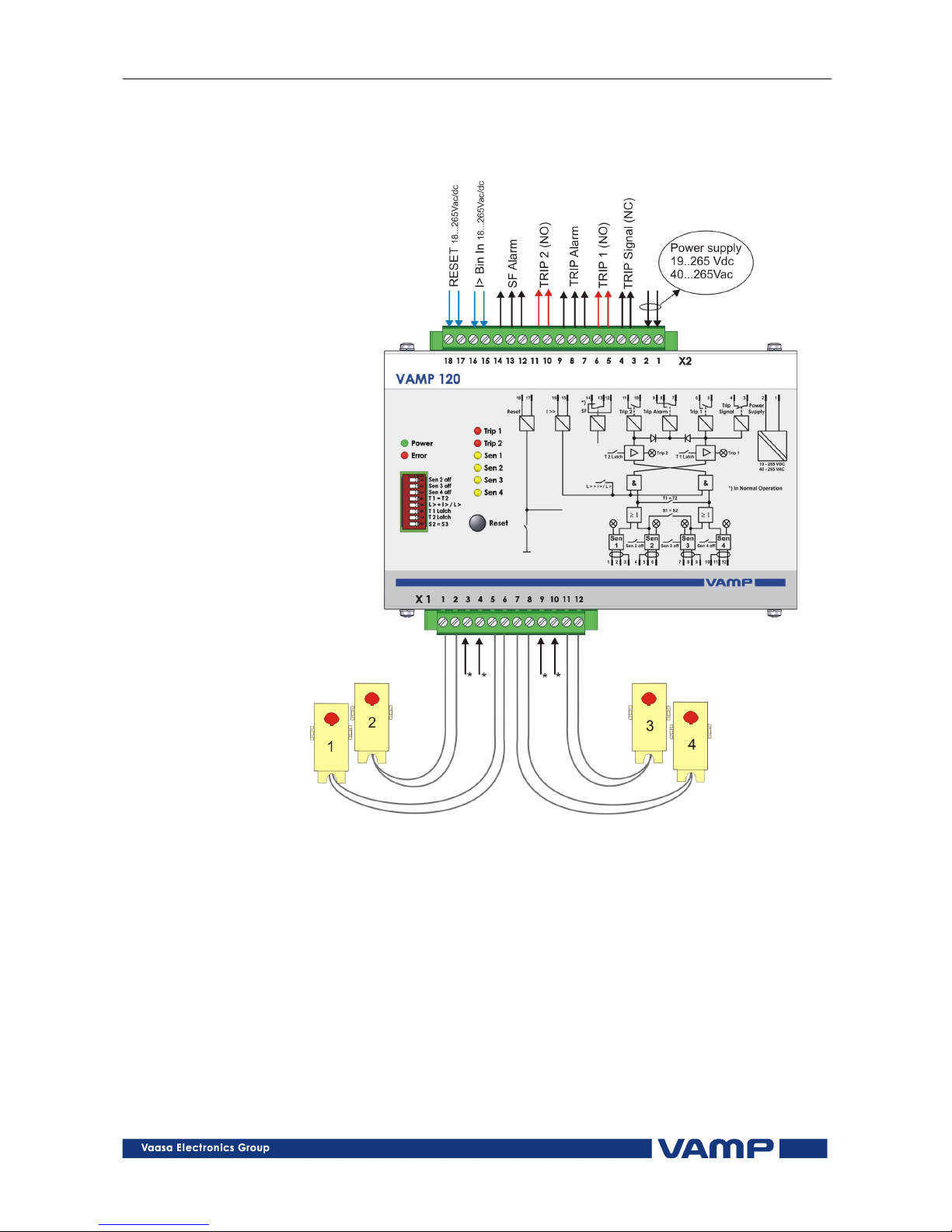

unit (VAMP 221 / VAM 4C). It is possible to connect 4 arc

sensors, of the type VA 1 DA or VA 1 EH, to the VAMP 120

unit.