EN

8

2. Press on the purge bulb under the

carburettor 4 or 5 times, to allow the

gasoline to arrive on the return fuel

tank transparent gasoline pipe.

3. Move the starter lever of the

carburettor in this position.

4. With your left hand, grip the

brushcutter (make sure that the

machine is well-balanced and the

handles are in suitable position for you)

and with the right hand pull slowly the

handle recoil starter until the pawls

hook onto the flywheel.

5. Pull hardly 4 or 5 times the handle

recoil starter until the starting, the red

button return on <<OFF>> position

when you push on the gas lever.

6. Release the starter lever after starting

on this position .

7. Never pull the recoil starter to its all

length in order to avoid damages to

the recoil starter.

If the engine does not start, maybe the

spark plug is wet. In this event, unscrew

the spark plug, wipe and dry it and pull the

recoil starter several times, without the

spark plug in place, in order to clean and

ventilate the combustion chamber.

IMPORTANT:

Whenever the engine is hot, all these

operations are not necessary, pull only

the recoil starter until the engine starts.

The cutting device should not be in

rotation at the idle speed of the engine.

Running-up

During the first ten hours of work, run the

engine at a moderate rpm. We advise you,

in any case, do not use your engine at high-

speed as the different components must

adjust one with the others during the

running-up period. It is at the end of the

running-up period that the engine will

reach its maximum power.

After the two first hours of work, make a

pause and check that all nuts and screws

are securely fastened, tighten if necessary.

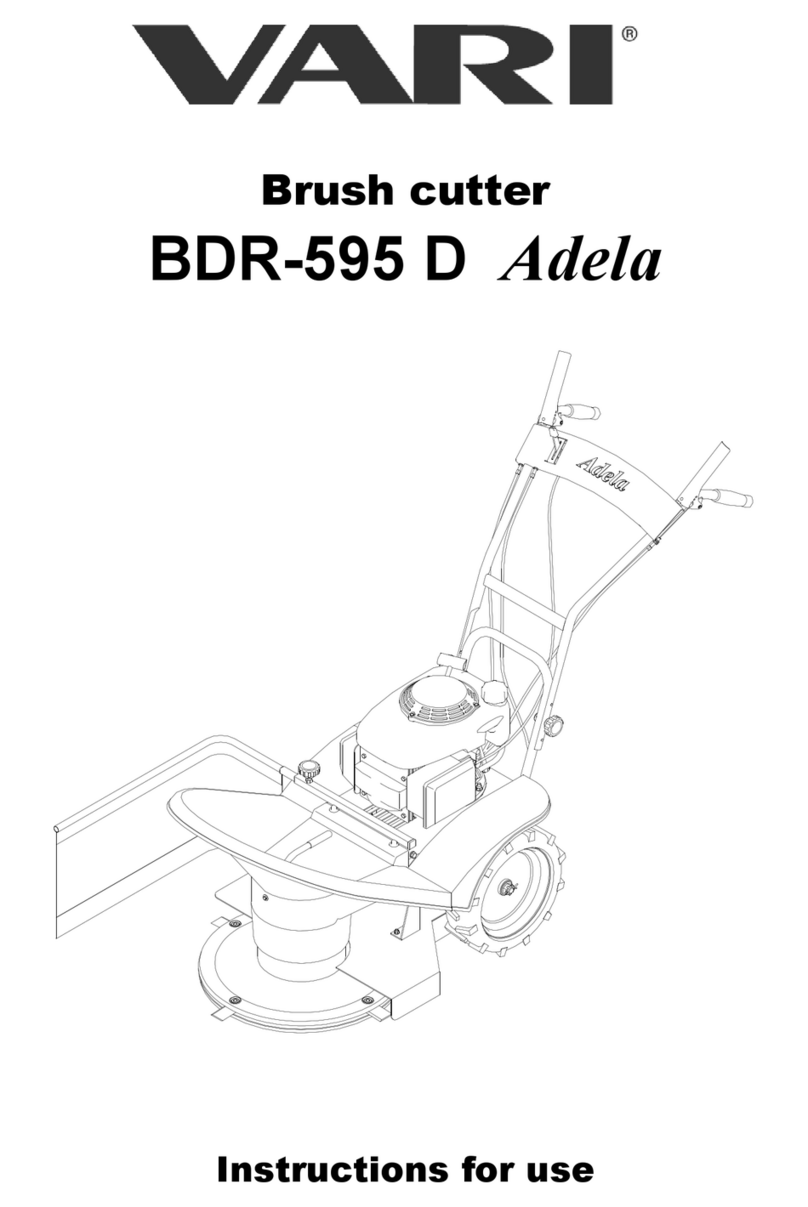

USE OF THE BRUSHCUTTER

Which protection to use with which

cutting tool?

Always use the safety guard supplied

with the brushcutter.

Use only the tools supplied by the

manufacturer. All other blades and

especially saw blades are

FORBIDDEN.

This brushcutter is only made to cut grass,

bushes, arborescent shrubs and clumps.

* Be sure that the weight of the machine is

perfectly balanced between the engine and

the cutting system. The cutting tool must

be parallel to the ground.

* Operate a few accelerations, without

reaching the max. rpm and without

working to make sure that everything is

working in good condition and regularly.

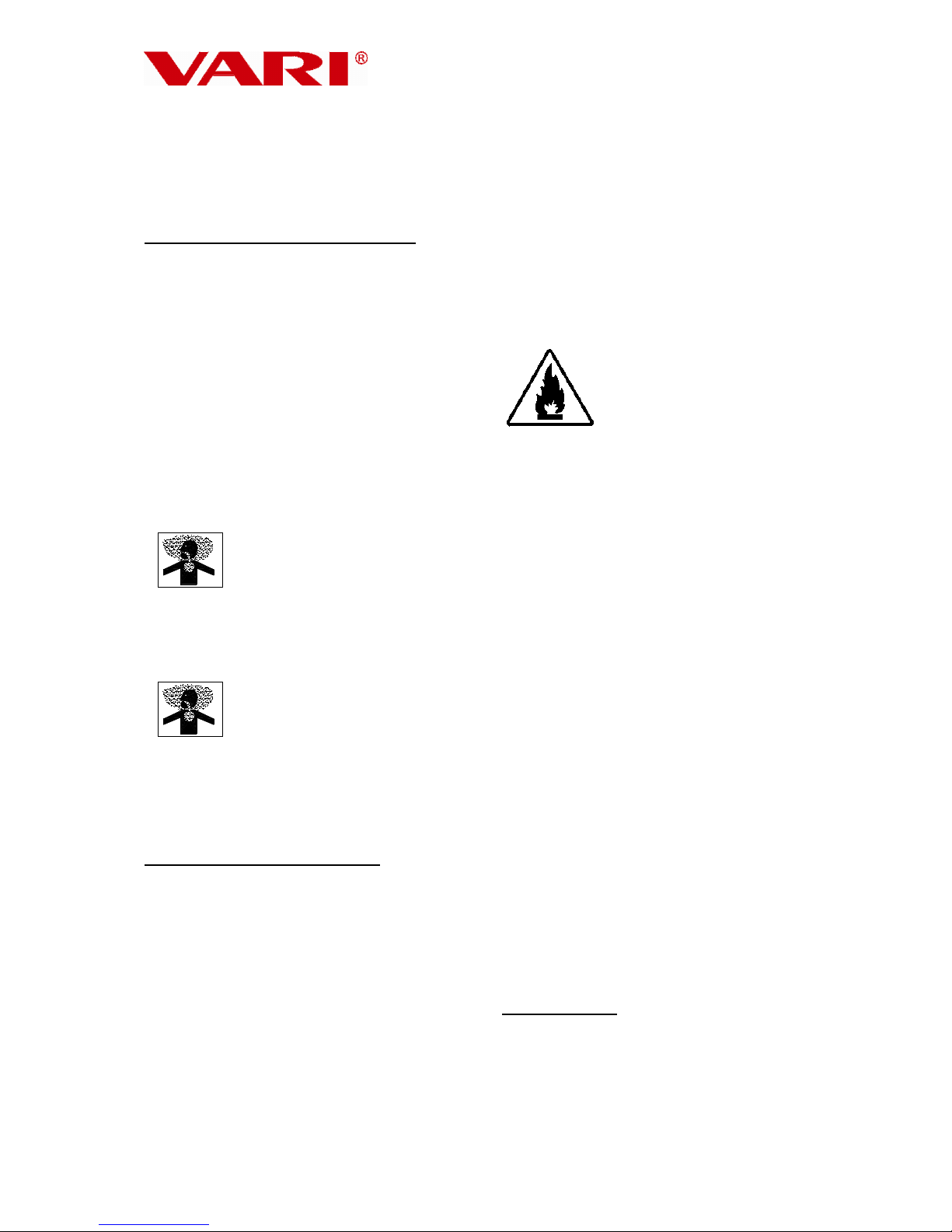

* Only when the nylon head or the 3-teeth

blade is at complete stop, you can go to

your working zone by carrying the

machine in a way that the cutting tool is

under your waist level and far from your

body. Make sure there are no other people,

animals or others within a 15 meters

radius.

3

6

0

°

15m

50ft

Place yourself in a well-balanced and

stable position on both feet.