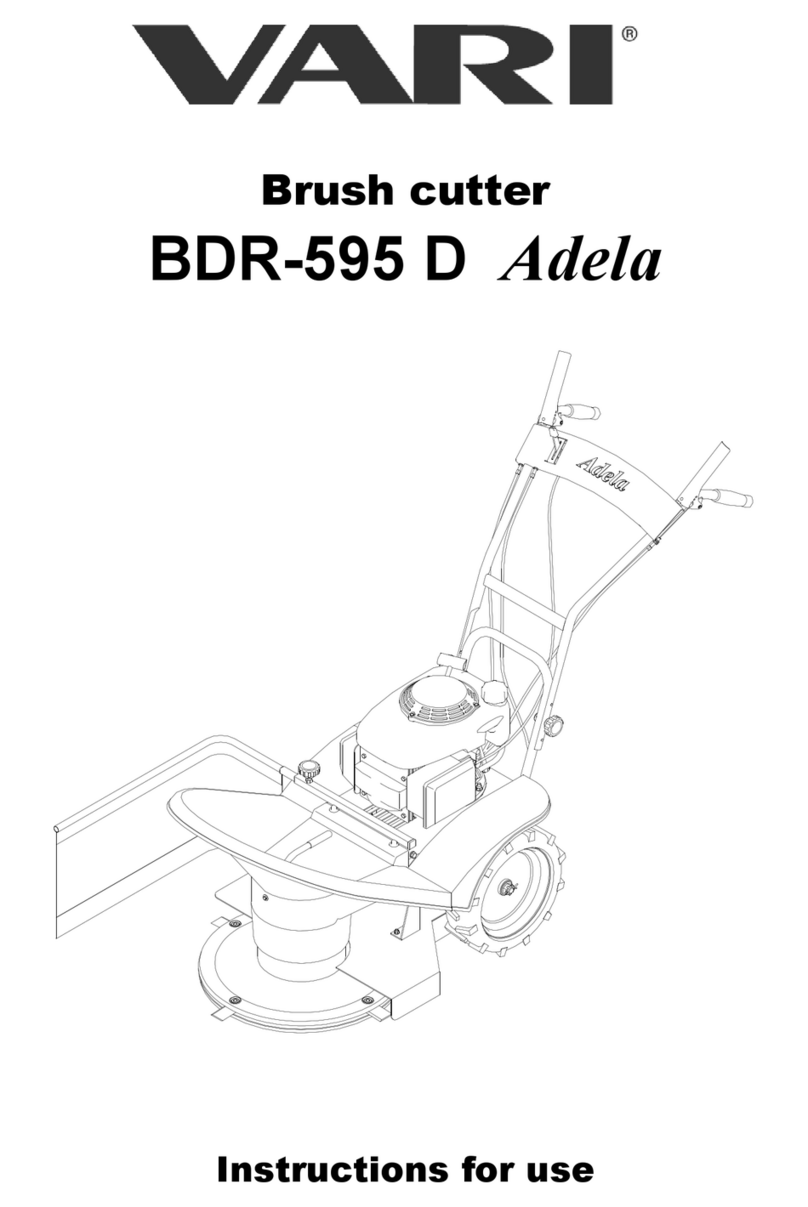

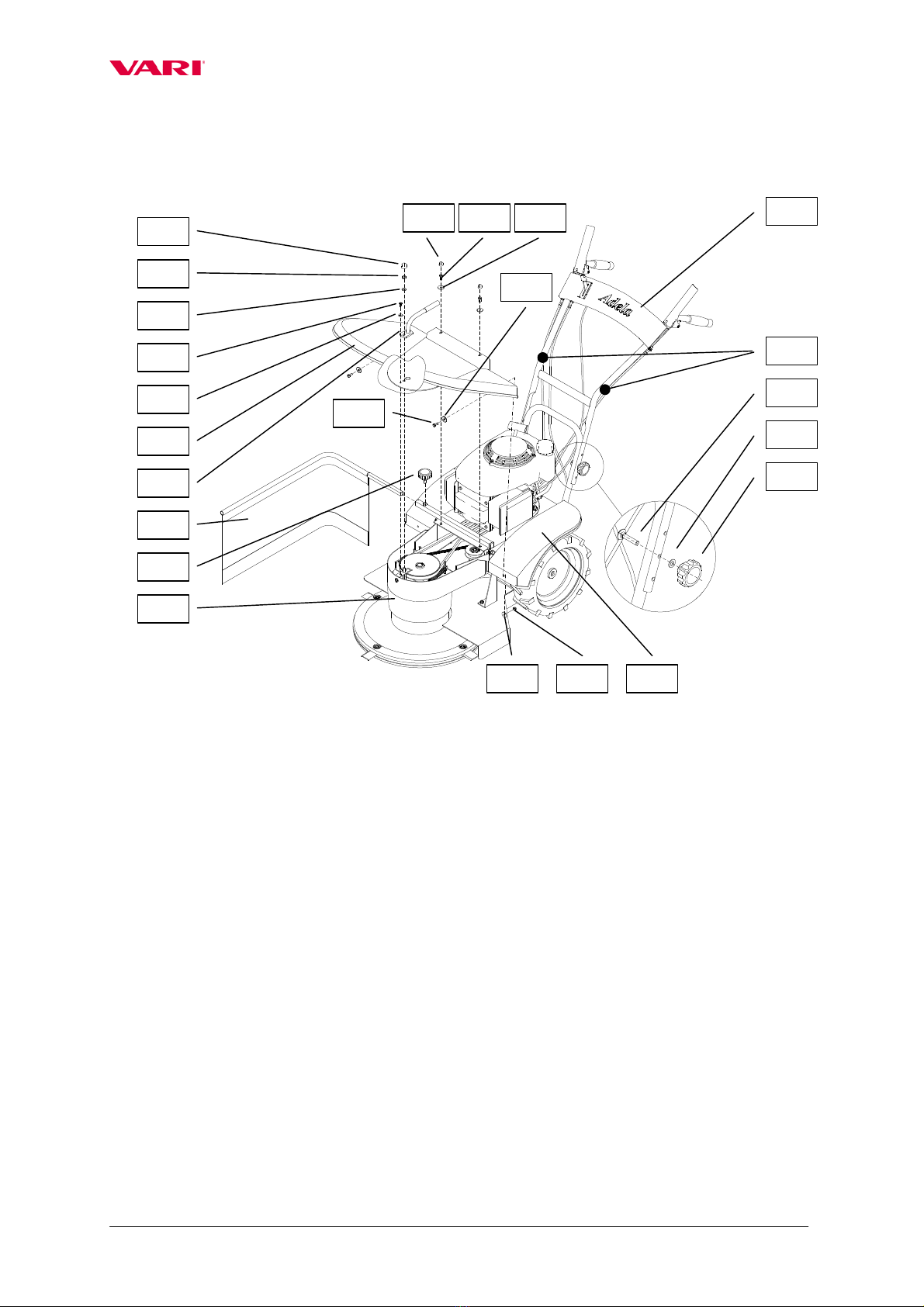

BDR-595 GMI Adela 190

2

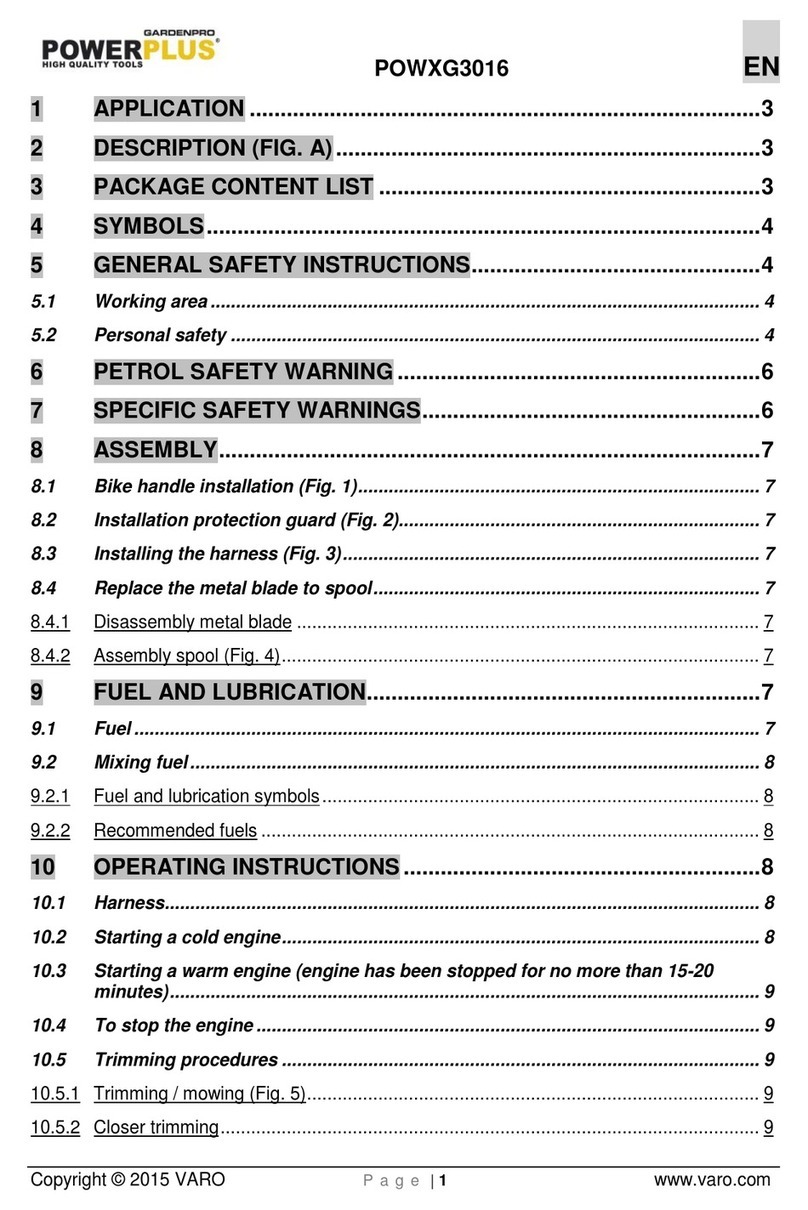

1 Basic information..............................................................................................................3

2 Introduction.......................................................................................................................4

2.1 Warning. .....................................................................................................................4

3 Operation safety. ...............................................................................................................5

3.1 Safety regulations. ......................................................................................................5

3.2 Declared and guaranteed noise and vi ration values..................................................6

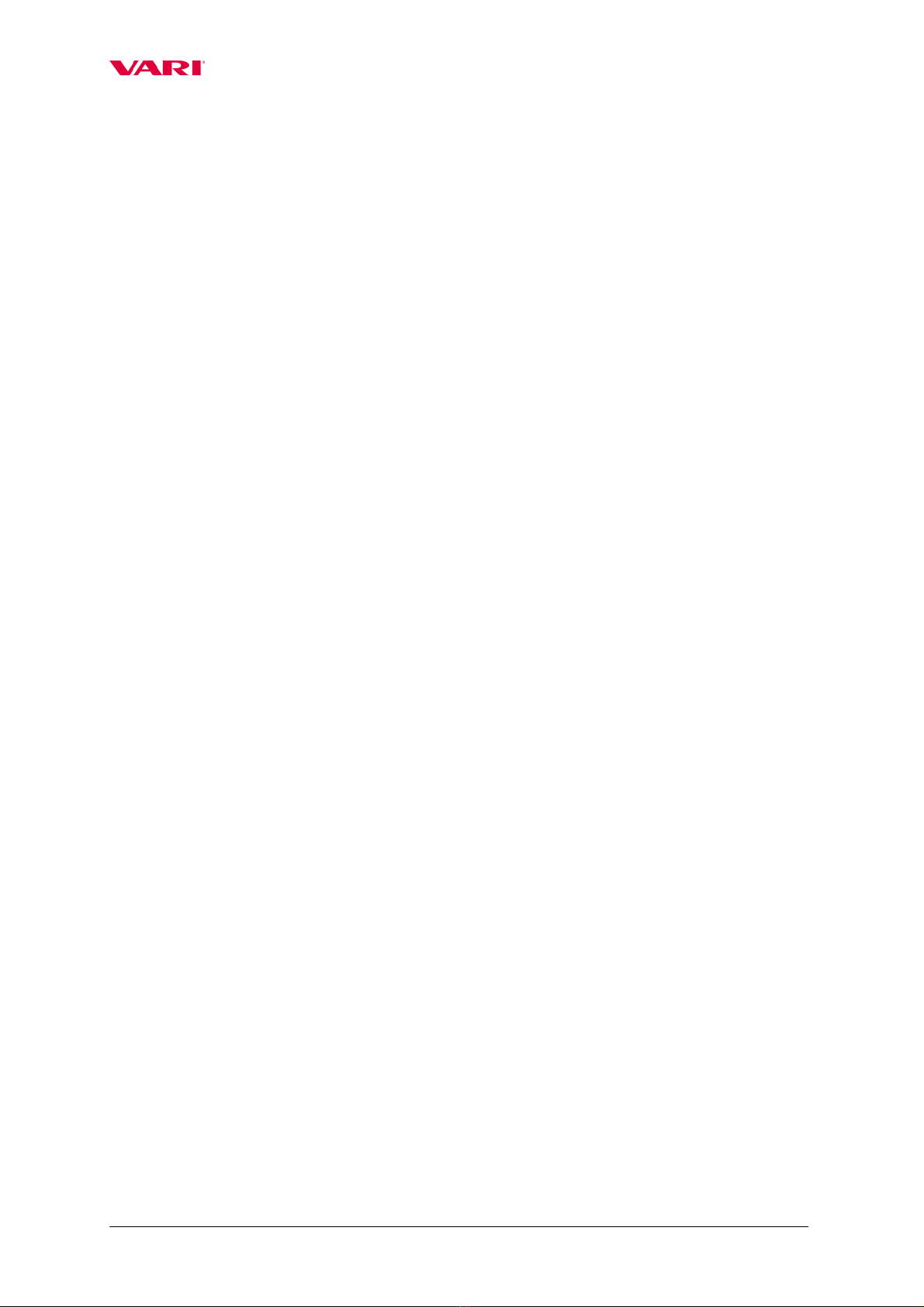

3.3 Safety pictographs. .....................................................................................................6

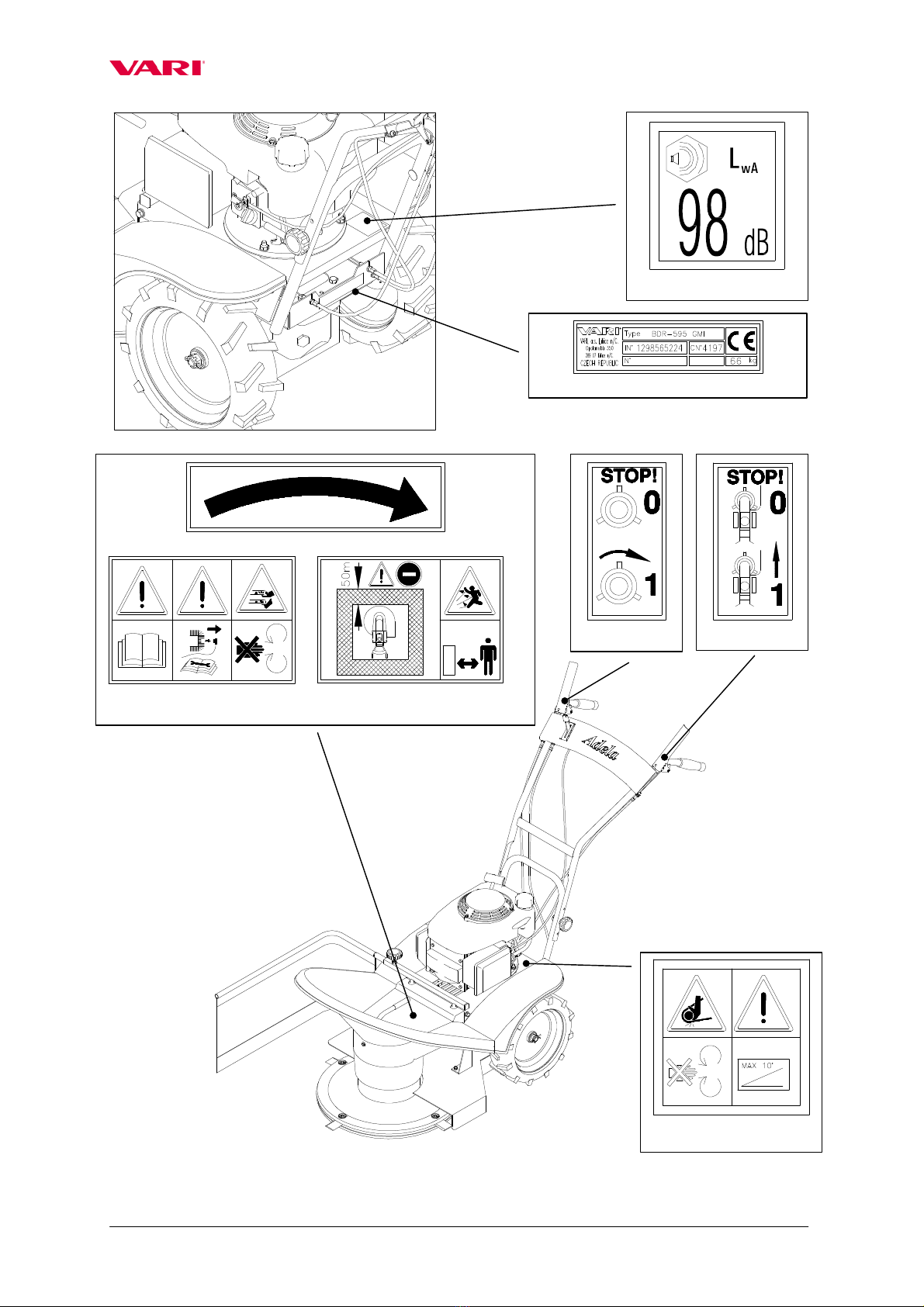

4 Use, technical specification and technical description of the machine.............................8

4.1 Using the machine. .....................................................................................................8

4.2 Technical specification. ..............................................................................................8

5 Instructions for use............................................................................................................9

5.1 Assem ling the machine.............................................................................................9

5.2 Putting the machine into operation...........................................................................10

5.3 Starting the cutting disk............................................................................................10

5.4 Machine travel. .........................................................................................................11

5.5 Stopping the machine. ..............................................................................................12

5.6 Working with the machine........................................................................................13

5.6.1 Working width of the machine. ........................................................................13

5.6.2 Cutting the stands. ............................................................................................13

5.6.3 Pro lems at cutting. ..........................................................................................13

6 Maintenance, care and storage. .......................................................................................14

6.1 Machine lu rication..................................................................................................14

6.1.1 Gear ox oil replacement and refilling..............................................................14

6.1.2 Engine oil replacement. ....................................................................................15

6.1.3 Ta le of machine lu rication............................................................................16

6.2 Tightening the olted connections............................................................................17

6.3 Replacement and sharpening the working lades.....................................................17

6.4 V- elt replacement and adjustment of tightening pulley..........................................18

6.5 Adjusting the litz wires of pulley, rake and wheel drive clutch. ............................20

6.6 Diagnostics of driving pro lems...............................................................................21

6.7 Ta le of service operations.......................................................................................22

6.8 Washing and cleaning the machine. .........................................................................22

6.9 Machine storage........................................................................................................23

6.10 Disposal of packaging and machine after the end of service life. ............................23

7 Instructions for ordering spare parts. ..............................................................................24

8 Contact to manufacturer:.................................................................................................24

9 List of components..........................................................................................................24

9.1 Machine casing .........................................................................................................25

9.2 Handle ars ................................................................................................................27

9.3 Cutting disk drive .....................................................................................................29

9.4 Wheel drive...............................................................................................................31

9.5 Gear ox.....................................................................................................................33

10 Letter of Guarantee .........................................................................................................35

Text and illustrations c 2006 VARI,a.s.

Pu lication No. VL-105-2006