8Värmebaronen EK 13

Operation and maintenance

After installation, check with the installer that the system is in

perfect condition.

Ask the installer to demonstrate the control and functions so

that you know how the system should work and be maintained.

Check that:

- No tools have been left in the cartridge's connection space.

- The electric cartridge and the heating system have been filled

with water and vented.

Air may remain for a while, for which reason a few more checks

should be made.

- Pipe connections are leakproof.

- Safety valves work. Water must enter the blow-off pipe when

the valve is operated.

- Start the electric cartridge by switching the main switch to

position 1.

Set the thermostats to the required temperature.

As the cartridge has been without power, the connection delay will

limit the power connection for the first two hours.

- The circulation pump works and has the right speed.

- Heat is distributed to the radiator system.

- The temperature matches the temperature selected. It may take

a while before the temperature in the system has been stabilised.

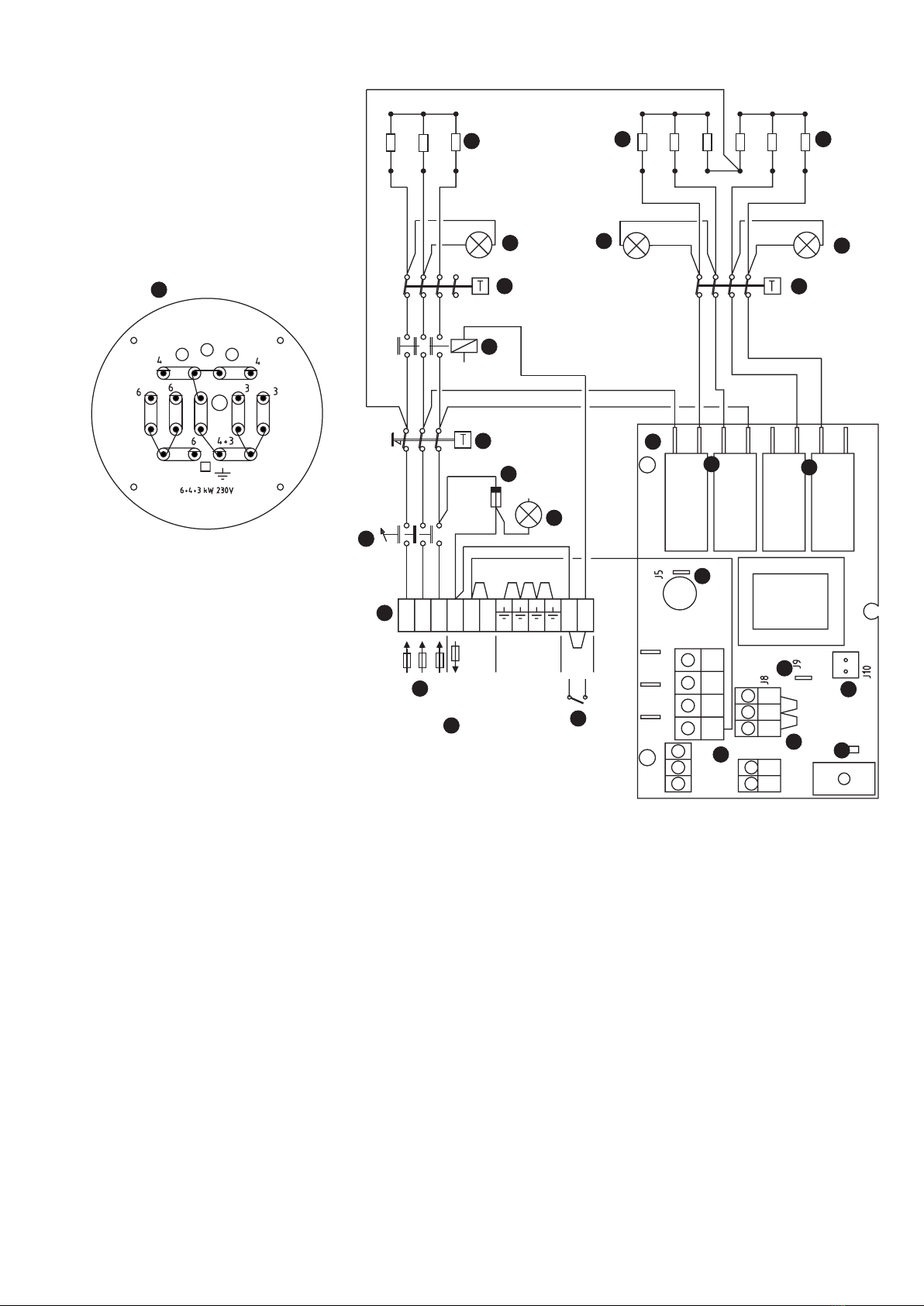

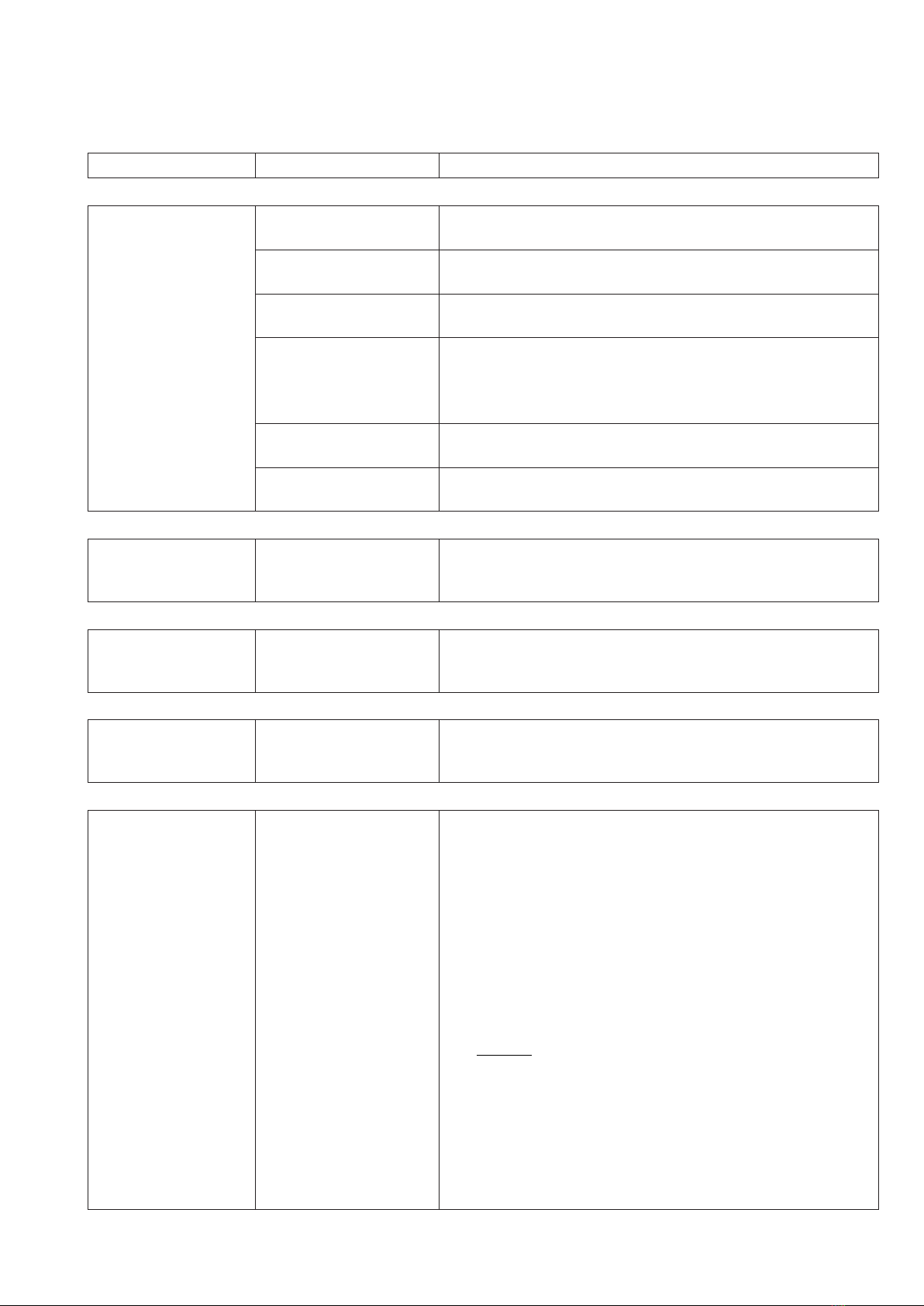

Control panel

5

8

6

10

17

11

16

7

15

5. Main switch.

6. Operation indicator.

7. Miniature circuit breaker.

8. Reset overheating protection.

10. Thermostat for power stage one.

11. Indicator for power stage one.

15. Indicator for power stage two.

16. Indicator for power stage three.

17. Thermostat, power stages two and three.

Operation

The electric power is controlled by two thermostats. The thermo-

stats have a difference of approximately 5 °C between breaking

and closing. This means that if the thermostat is set to 65 °C, it

breaks when the temperature reaches this level. The thermostat

closes again when the temperature has fallen to approximately 60

°C.

The thermostat for power stages two and three works in two

stages. Stage two is connected at 5 °C lower than stage three.

Otherwise it works in the same way as the thermostat for power

stage one.

Overheating protection

The electric cartridge has overheating protection that is triggered

when the temperature exceeds approximately 95 °C.

The overheating protection is reset on the side of the electric

cartridge. It may only be reset when the temperature has fallen

below 80 °C. You need to press quite hard to reset the protection.

Venting

Check regularly that there is water in the system. After venting,

the pressure must be checked and water may need to be added.

Action in the event of electrical operation

When EK 13 is installed as a supplement to a boiler and the electric

cartridge takes over the heating, any unnecessary air throughput

and thus cooling of the boiler should be avoided.

Safety valve

To maintain safety protection, any safety valve should be operated

regularly, approximately four times a year.

Draining

If the heating system needs to be drained of water, the electric

cartridge must first be switched off so that the immersion heater

is not damaged.

Action in the event of a risk of freezing

When it is extremely cold, no part of the heating system must be

switched off as there is a risk of bursting. If you suspect that any

part of the system is frozen, contact an installation engineer.

If the system is to be switched off for an extended period of time,

the system should be drained or filled with water mixed with glycol.

Frost protection

If the system water is mixed with glycol, it is important for the

glycol to contain a suitable quantity of corrosion-protection agent.

When glycol breaks down, carbonic acid is produced, which

increases the risk of corrosion.

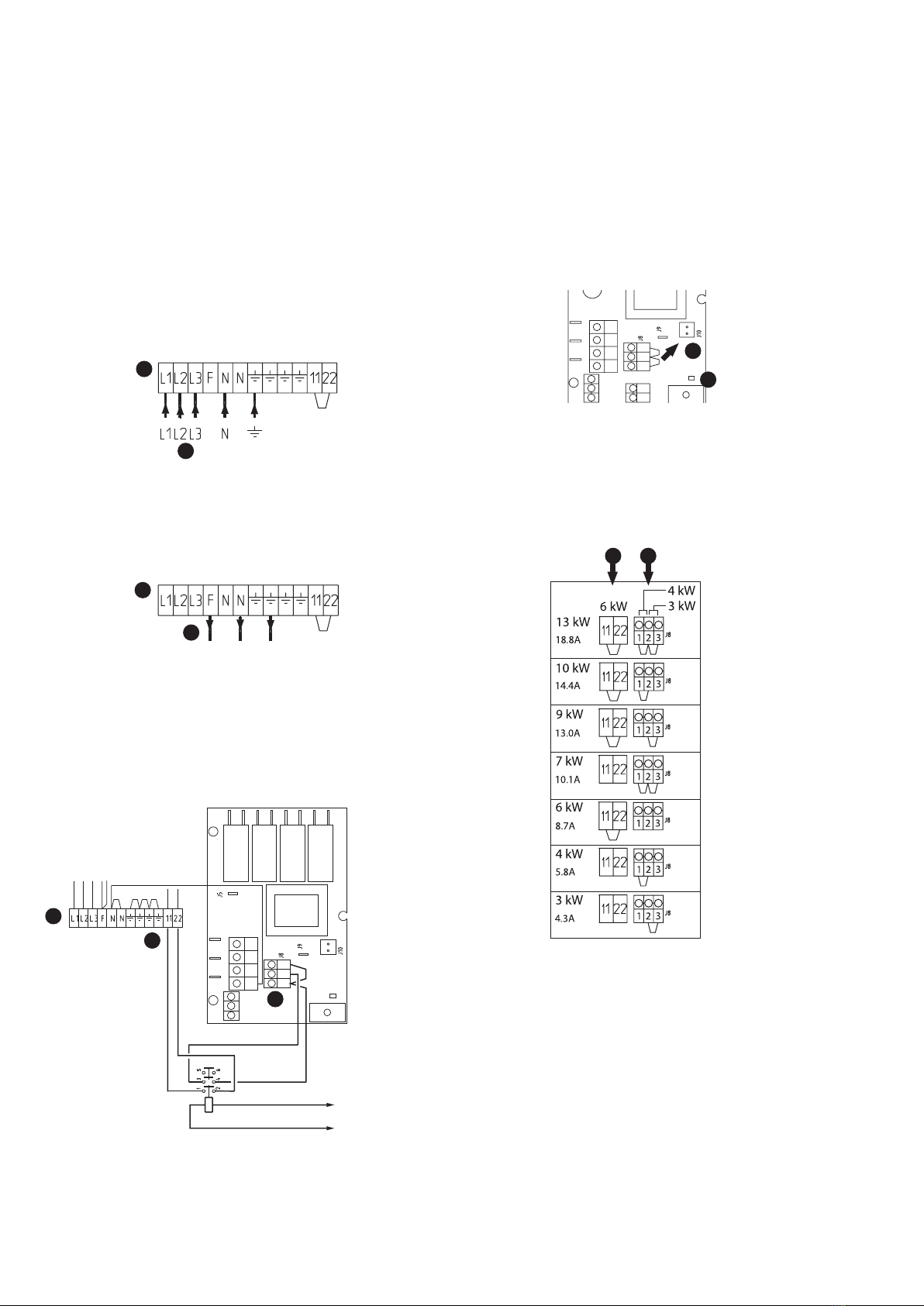

Connection delay

According to the standard, a maximum of 6 kW may be con-

nected directly. The remainder must be delayed for two hours.

This means that, after a power cut that has lasted for longer than

three minutes, only two of the electric cartridge's power stages are

connected directly. The remainder are connected (if required) two

hours after the power has returned.