10

Värmebaronen EK 15E

Operation and maintenance

Before starting, check that the installation is in a

fullysatisfactory condition.

Ask the installation engineer to demonstrate

the controland functions so that you know how

thesystemworks and must be maintained.

Check:

• Boiler and heating system are filled with water,

ventedand that the pressure is correct.

• That all necessary valves are open.

• That any safety valves are working.

• That any external safety equipment is working

asintended.

• That the circulation pump is working and

theflowdirection is correct.

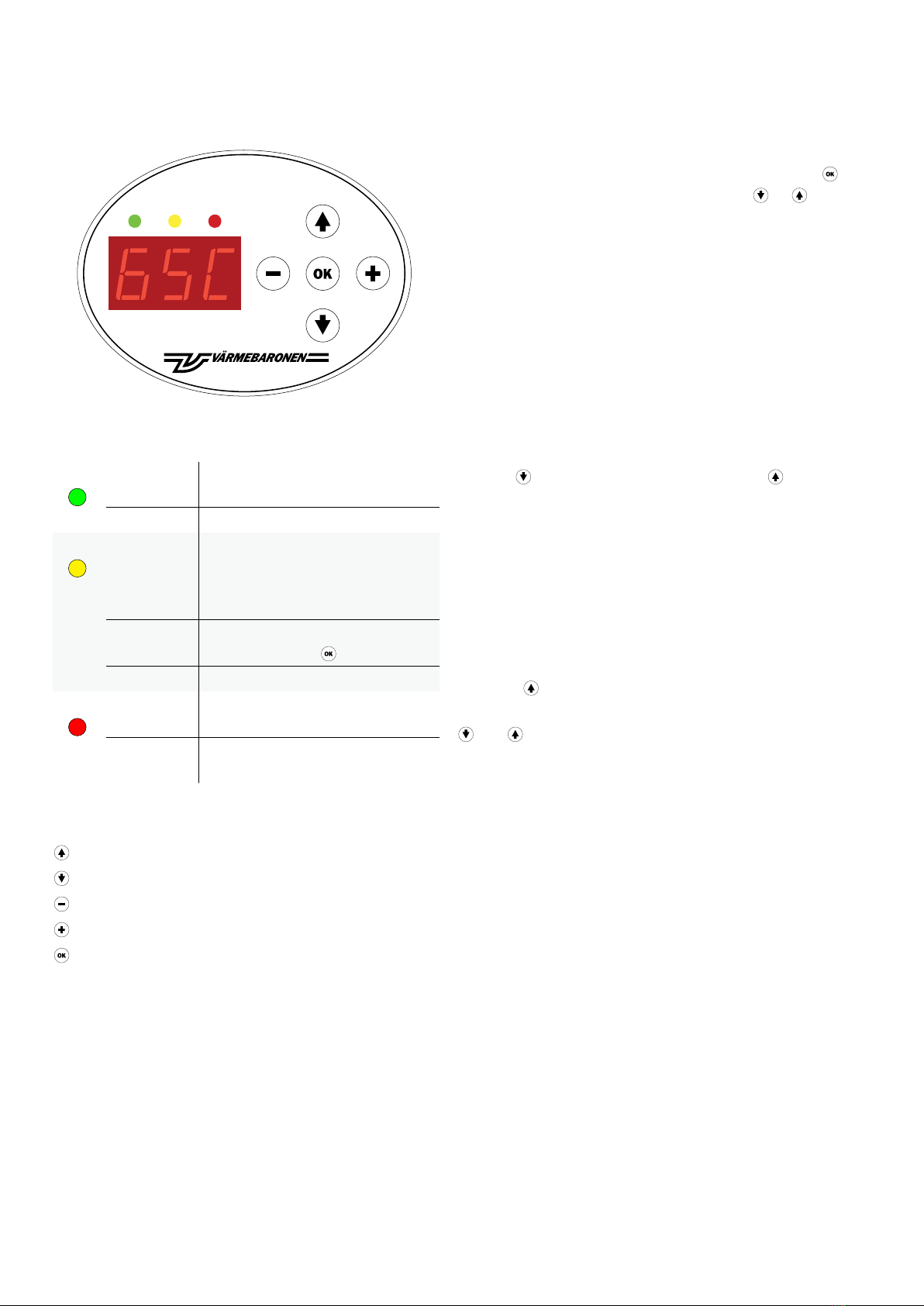

Start

Energised electric flow heater, the display illuminates

alongwith a green indicator.

A number of parameters are shown below that should

beconsidered when starting:

For installation/ configuration, see "Menu-

Management"!

• Stage restriction; "Service level" row 5.

• Load guard; "Service level" row 3.

• Circulation pump; "Advanced Service level"

rows20and23.

• External control/ Output control; "Advanced Service level"

row 13.

• ECO-mode; "User level" row 12.

Depending on whether the electric flow heater will be

controlled by a fixed or outdoor-compensated, UTK, setpoint.

For the UTK function, the electric flow heater must be

supplemented with an outdoor temperature sensor, optional.

• Desired boiler temperature; "User level" row 1.

• UTK; "Advanced service level" rows 5, 6, 7, 8 and 9

and"Service level" rows 6, 7 and 8.

• Room unit; "User level" rows 10 and 11 and

"Servicelevel"row 8.

The room unit is an option and requires that the

UTKfunction is activated.

Depending on the selected connection delay upon restart

after power failure, a connection delay can be applied for

output connection over 6kW, see "Advanced Service Level"

line 14.

For testing and service, the connection delay and

outputconnect/ disconnect can be temporarily sped up,

see"Service level" rows 1 and 2.

The electric flow heater should now step in the number

ofoutput stages needed until the temperature conforms

tothe set value.

Connection delay

According to the recommendations, a maximum of 6kW

ofthe output should be connected immediately after

avoltage loss.

See "Advanced Service level" row 14.

Circulation pump

Operating modes for circulation pump, see "Advanced

Service level" rows 20 and 23.

Load guard

The load guard protects the main fuses against overload

byreducing the electric flow heater's output. When the

overload ceases, the output is reconnected stage by stage.

See "Service level" row 3.

Stage restriction

The flow heater can be stage restricted in 1-7 stages.

Thenumber of stages selected corresponds to the installed

output. See "Service level" row 5.

Output limitation/ Output control, 0-10V

Output restriction; the electric flow heater's temperature

control is superior; the setpoint must be set slightly higher

than the required temperature.

Output control, only the overtemperature limit restricts. Used

together with another unit with its own temperature control.

See "Advanced Service level" row 13.

Desired boiler temperature

Desired boiler temperature, setpoint, see "User level" row 1.

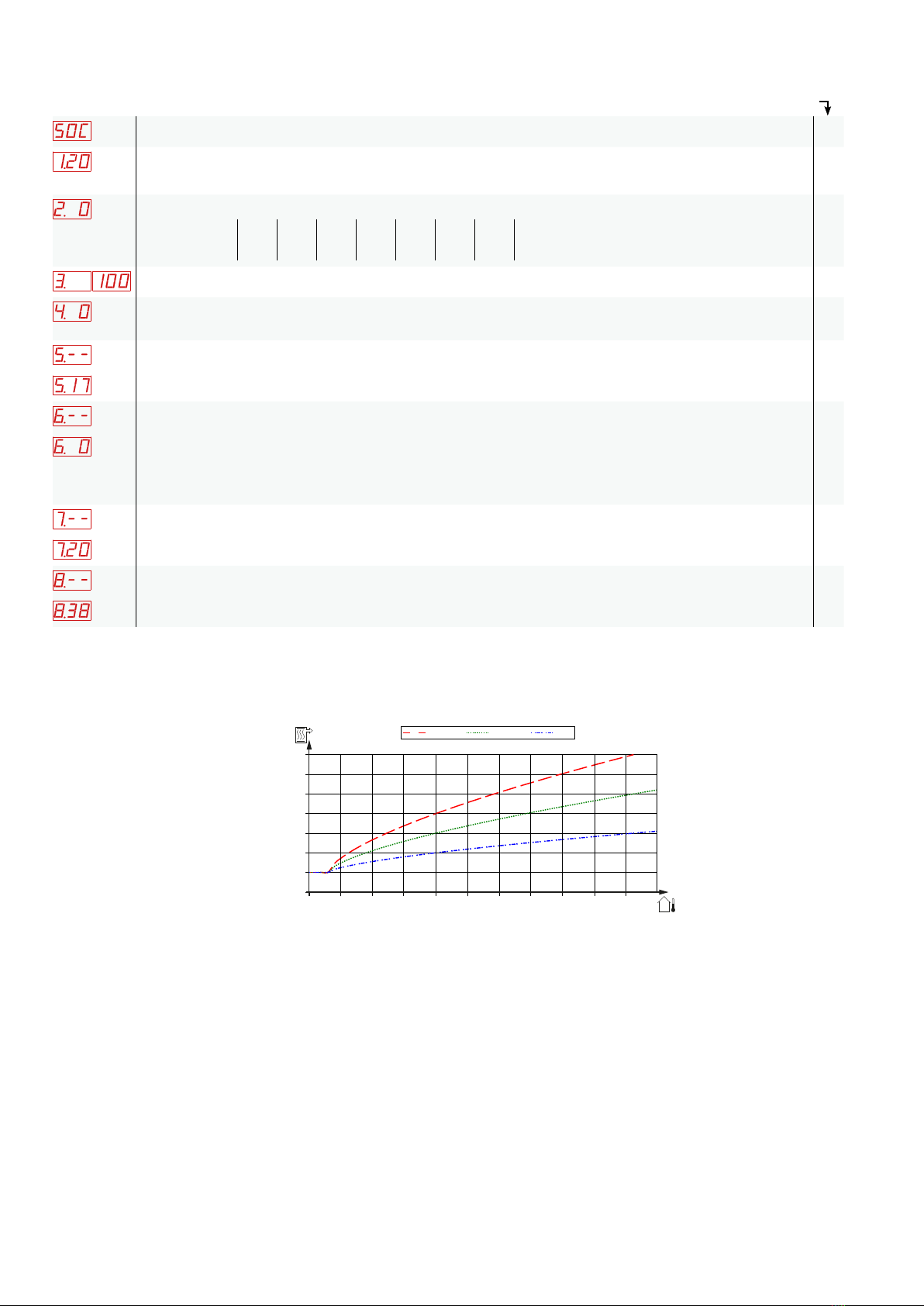

Outdoor temperature compensator setpoints, UTK

The Elomax electric flow heater must be supplemented with

an outdoor temperature sensor-option. This function must

beactivated in the menu system.

See "Advanced level" rows 5, 6, 7, 8 and 9 and "Service

level" rows 6, 7 and 8.

Alternative temperature

This function requires that the UTK function is activated and

an external contact. Can be used for night-time reduction,

holiday mode or similar, see "User level" rows 6 and 9.