021. Precautions

Warning: This is not a medical device and is not considered life-sup-

port or life-sustaining equipment.

Warning signs on the product are designed to help users understand and

use this product correctly to prevent damage and a property loss.The

main warning signs and meanings are as follows:

▲The machine shall be placed indoors. Keep the room well-ventilated

and avoid direct sunlight. Keep the product more than 30 meters away

from the walls and other objects.

▲Do not place miscellaneous items and liquid containers on the machine

case.

▲It is prohibited to stack sundries at the ventilation hole on the back of

the machine to prevent clogging of intake and exhaust, which may lead to

excessive temperature and thus cause improper shutdown or a decrease

in oxygen concentration.

▲To avoid the machine being interfered by strong electromagnetic

environment or interfering with other electrical appliances, please keep it

at least 3 meters away from other household appliances when using.

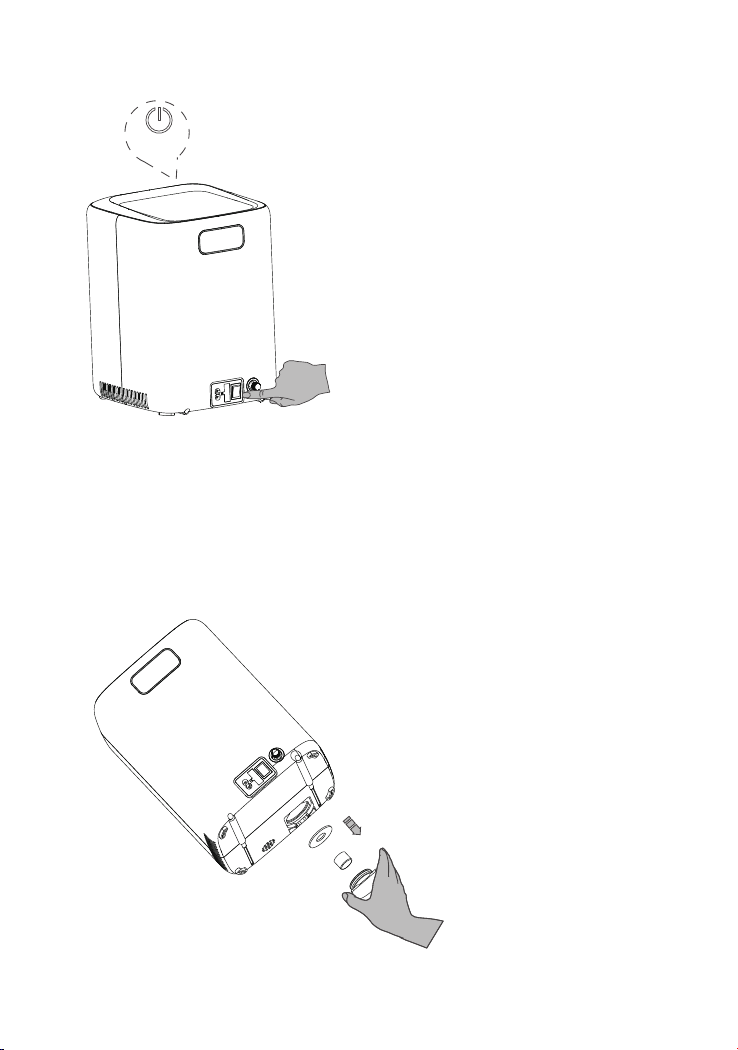

▲Do not place the machine upside down or laid it horizontally.

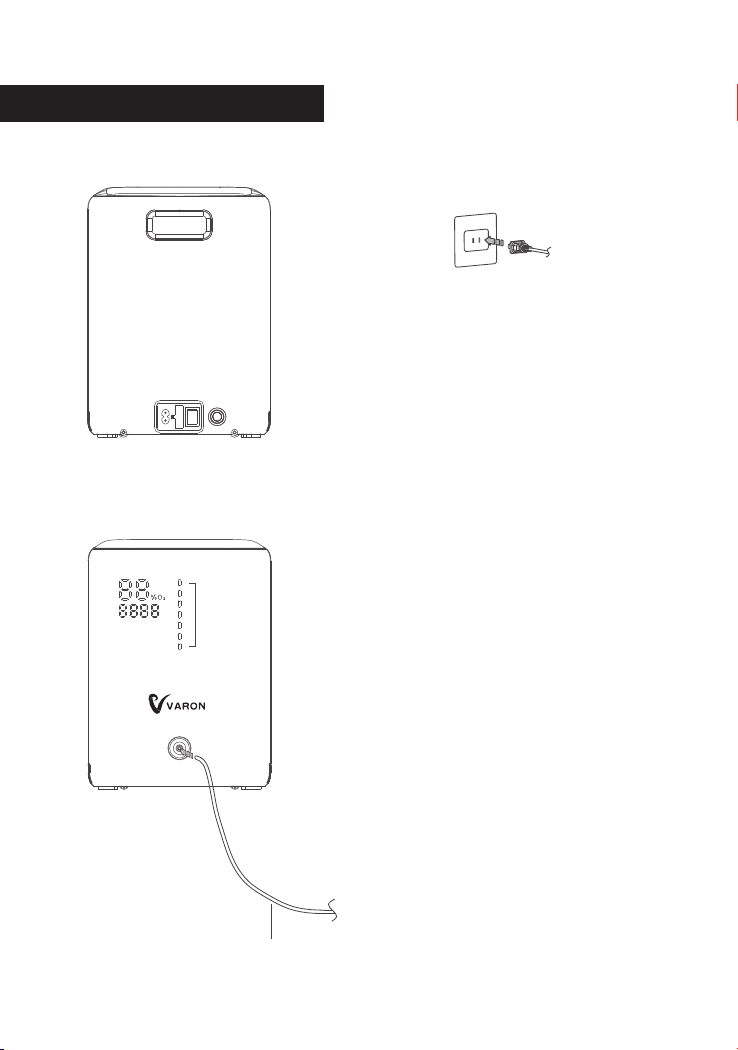

▲If the voltage is unstable and exceeds the range of 220±15V, please

connect the voltage regulator before use.

▲Please use a safe and qualified socket and a terminal block with safety

electrician certification.

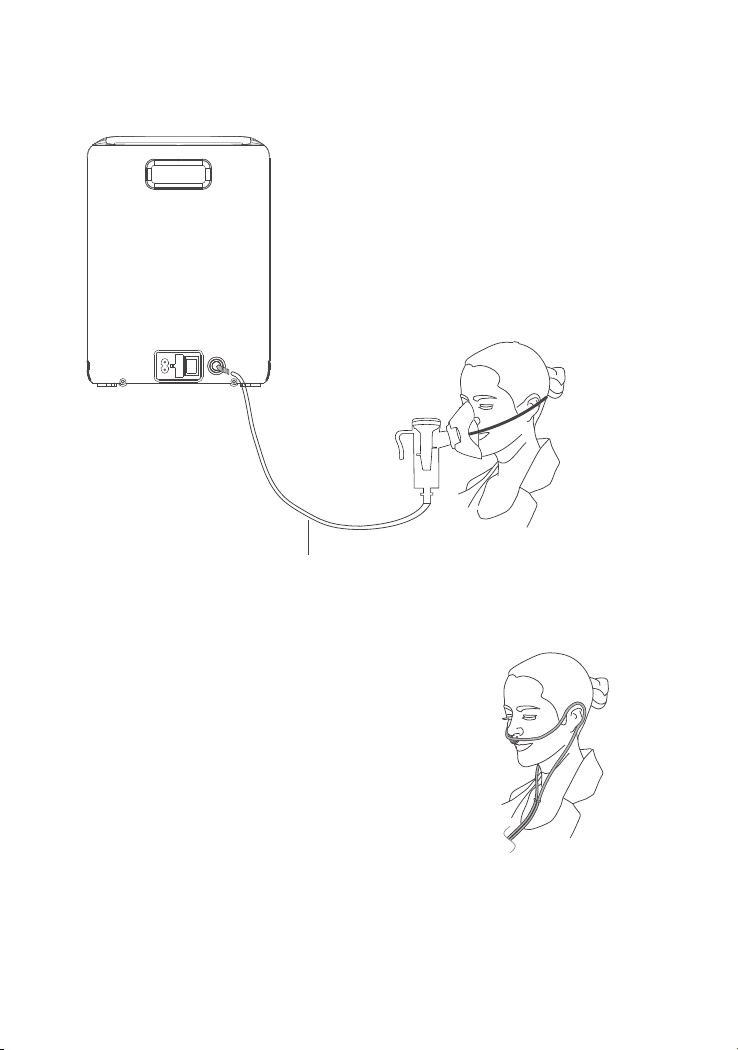

▲Oxygen is a combustion-supporting gas. Therefore, when using the

machine,do not smoke and keep away from the fire source to avoid a fire

hazard.

▲Do not turn on and off the machine too often. Turn off the machine for

3-5 minutes before restarting to maintain the normal service life of the

machine.

Prohibited action

Required action

Keep dry

Caution (Warnings and dangers)

Class II equipment

This side up