Installation, Operating & Maintenance Instructions

Series 570, DN 63 (2 ½")

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

5 Maintenance & repairs

Under clean operating conditions, the valve does not require any maintenance during the specified cycle life.

Contamination from the process may influence the function and requires more frequent maintenance.

Before carrying out any maintenance or repairs, please contact VAT. It has to be individually decided whether the

maintenance/repair can be performed by the customer or has to be carried out by VAT. The fabrication number on the

valve

. . . . . – . . . . – . . . . / . . . .

has always to be specified.

All supplies (e. g. compressed air, electrical power) must be disconnected for removal/installation of the valve from/into the

system and for maintenance work.

Even with disconnected supply, loaded springs and/or air cushions in cylinders can be potential hazards.

Keep fingers and objects away from the valve opening!

Products returned to VAT must be free of harmful substances such as e.g. toxical, caustic or microbiological ones. If

products are radioactively contaminated, fill in the VAT form «Contamination and Radiation Report» and send it with the

product. The form is available at VAT. The maximum values indicated in the form must not be exceeded.

5.1 Preventive Maintenance

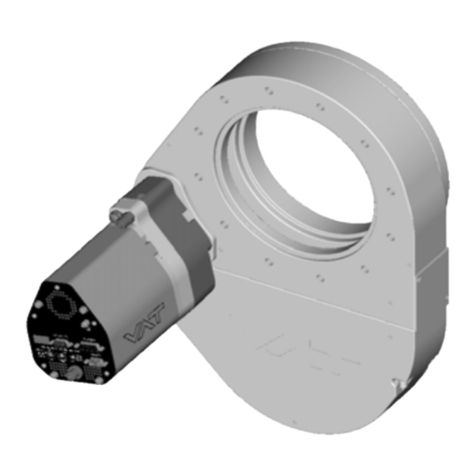

Instruction how to change the VATRING (Don’t touch inside valve parts without gloves)

Item number refer to the drawing on page 10.

- Open the valve and remove the bonnet screws (Pos.69).

- Remove valve insert and bonnet seal (Pos.36/2).

- When opening or tightening screw (Pos.67) the bellows must be protected against turning (torsion) shown on

the next page.

- Remove VATRING.

- Take a lint free tissue dabbed with alcohol and clean all sealing surfaces (plate, bonnet, body seat and VATRING).

- Check sealing surfaces (visually) for scratches.

- Clean VATRING and plate with clean and dry compressed air.

- Place VATRING on sealing surface of the plate.

- Align VATRING parallel with the frontal of the plate.

- Place holding ring on top of plate.

- Insert screw (Pos.67), protect bellow against turning, tighten screw (torque see list).

- Place new bonnet seal (fig.36/2) exactly like shown on next page (fitting position)!

- Put valve insert back into valve body and tighten bonnet screws in crosswise order (torque see list).

closing torque of screw with venting hole (pos. 67)

closing torque of bonnet screw (pos. 69)