c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

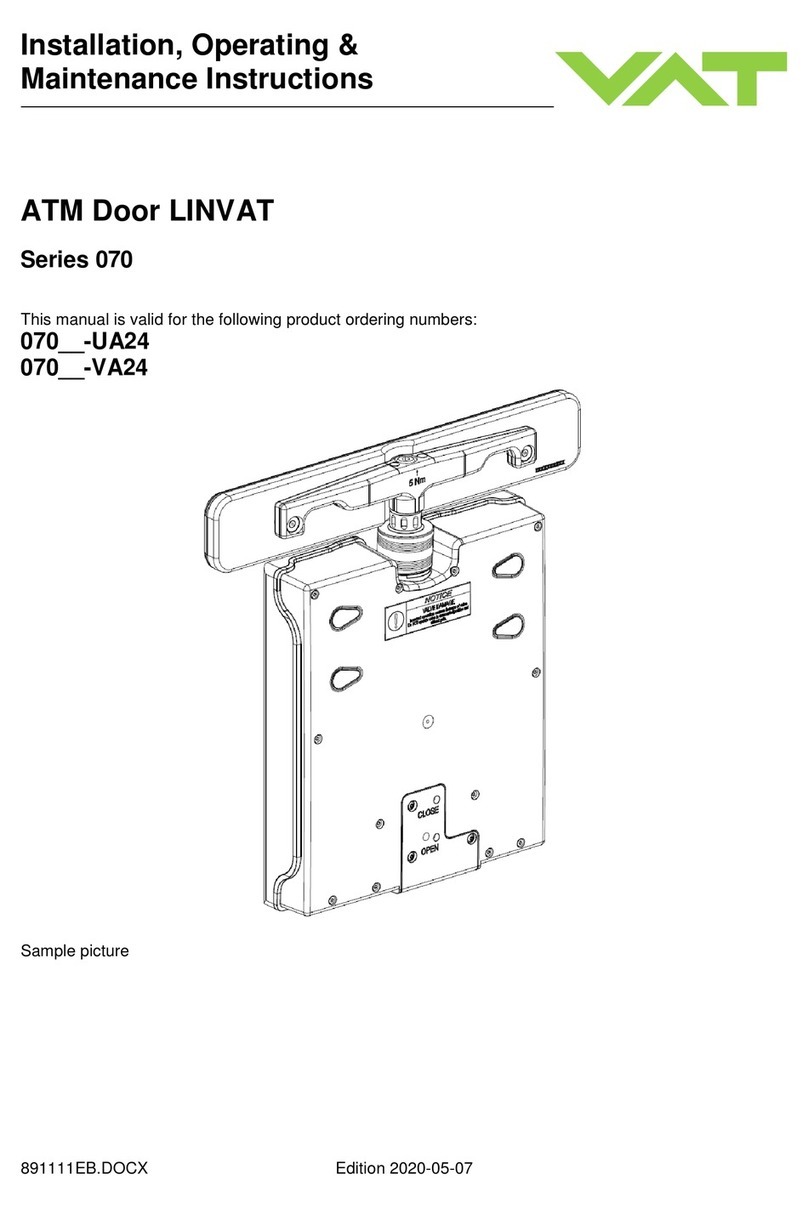

Installation, Operating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel

++41

81

771

61

61

Fax

++41

81

771

48

30

Email

rec

[email protected] http://www.vatvalve.com

225590EE 2005-04-26 8/16

Problem Recommendation

LOGIC interface installed:

Controller does not respond to logic

inputs

- Switch to «REMOTE»

- Verify that logic Interface is installed correctly

‘LOGIC’ is displayed on front panel during start-up.

LOGIC interface installed:

Controller does not respond to analog

position or pressure setpoint

- One of the 4 setpoints, OPEN or CLOSE digital inputs are activated

RS232C interface installed:

Controller does not respond to

RS 232 commands

- Verify settings of the switch S1 on the RS232C interface are correct

- Confirm that RS232C interface is installed correctly

‘MIXED’ is displayed on the LCD display during start-up

- Confirm that PM controller is in REMOTE

- Logic inputs on RS232C interface override RS232 commands

RS232C interface installed:

Controller responds with error message - Wrong command or transmission error, see chapter ‚9.3 RS232C Communication‘

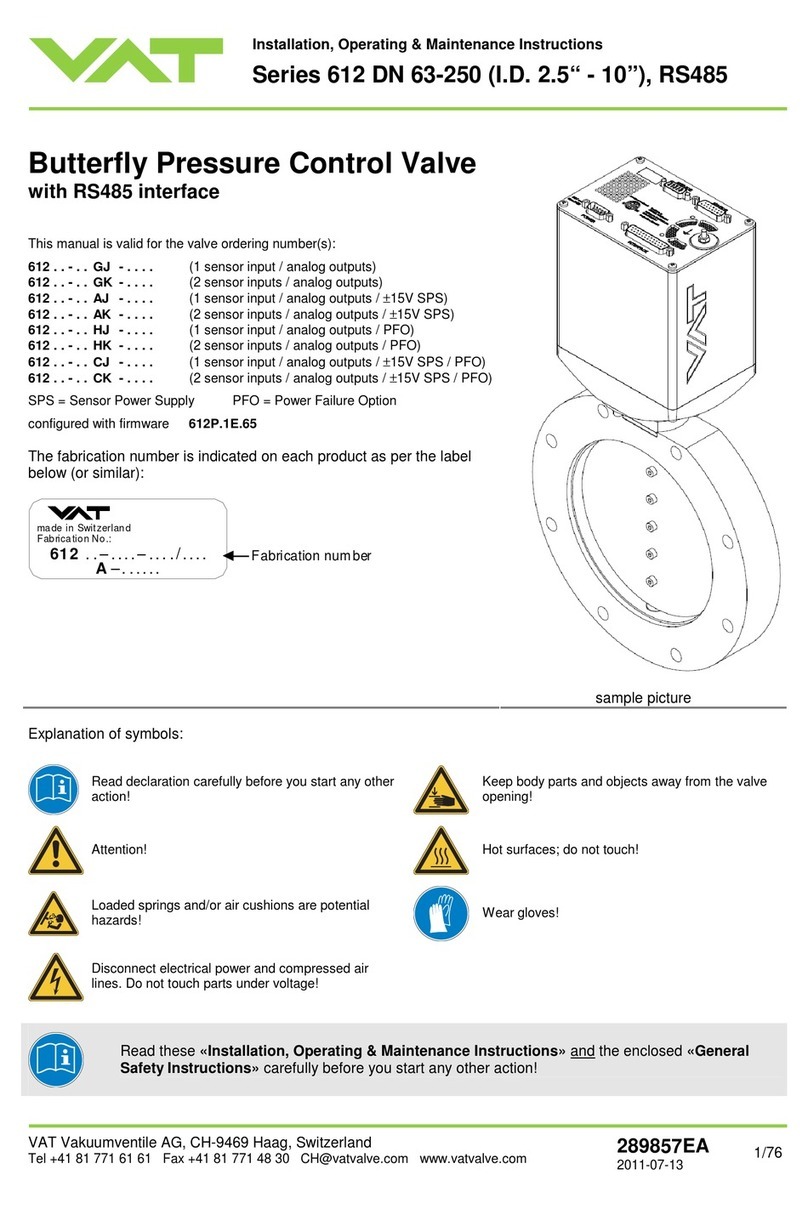

7 Repairs

Contact VAT for repair. Please check first the fabrication No. 641P . - . . . . . - . . . . - . . . .) marked on the rear panel of the

PM controller. Your VAT representative will discuss with you how the repair can be carried out best.

8 Warranty

Each product sold by VAT Vakuumventile AG (VAT) is warranted to be free from the manufacturing defects that adversely

affect the normal functioning thereof during the one-year period immediately following delivery thereof by VAT, provided

that the same is properly operated under conditions of normal use and that regular, periodic maintenance and service is

performed or replacements made, in accordance with the instructions provided by VAT. The foregoing warranty shall not

apply to any product or component that has been repaired or altered by anyone other than an authorized VAT

representative or that has been subject to improper installation or abuse, misuse, negligence or accident. VAT shall not be

liable for any damage, loss, or expense, whether consequential, special, incidental, direct or otherwise, caused by, arising

out of or connected with the manufacture, delivery (including any delay in or failure to deliver), packaging, storage or use of

any product sold or delivered by VAT shall fail to conform to the foregoing warranty or to the description thereof contained

herein, the purchaser thereof, as its exclusive remedy, shall upon prompt notice to VAT of any such defect or failure and

upon the return of the product, part or component in question to VAT at its factory, with transportation charges prepaid, and

upon VAT's inspection confirming the existence of any defect inconsistent with said warranty or any such failure, be entitled

to have such defect or failure cured at VAT's factory and at no charge therefor, by replacement or repair of said product, as

VAT may elect. VAT MAKES NO WARRANTY OR REPRESENTATION OF ANY KIND, EXPRESS OR IMPLIED,

(INCLUDING NO WARRANTY OR MERCHANTABILITY), EXCEPT FOR THE FOREGOING WARRANTY AND THE

WARRANTY THAT EACH PRODUCT SHALL CONFORM TO THE DESCRIPTION THEREOF CONTAINED HEREIN, and

no warranty shall be implied by law.

Furthermore, the «Terms of sale» at the back of the price list are applicable.