7.2.4 Manual mode........................................................... 45

7.2.5 Automatic mode....................................................... 45

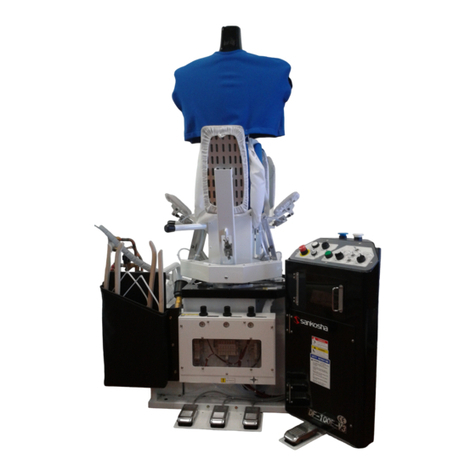

7.3 Controls and indicators............................................... 46

7.3.1 Control panel........................................................... 47

7.4 Starting the machine................................................... 65

7.5 Program sequence..................................................... 66

7.6 Switching off the machine........................................... 69

8 Maintenance and cleaning............................................... 70

8.1 Cleaning...................................................................... 71

8.2 Maintenance and inspection table.............................. 71

8.2.1 Battery replacement on touch panel PP65.............. 73

9 Remedy of faults/elimination of defects......................... 76

9.1 Alarm messages on the touch screen........................ 76

9.1.1 Error messages....................................................... 77

9.1.2 Warning messages.................................................. 80

9.2 Defect, cause, remedy................................................ 81

10 Emergency......................................................................... 82

11 Disassembly and disposal............................................... 83

12 Spare parts........................................................................ 84

12.1 Spare parts list.......................................................... 85

12.1.1 Spare parts, residual moisture control (option).... 105

12.1.2 Spare parts, pay per piece (option)..................... 106

12.2 Pneumatics diagram............................................... 107

12.3 Circuit diagram........................................................ 109

12.3.1 Circuit diagram 230 V........................................... 110

12.3.2 Circuit diagram 400 V.......................................... 125

13 Options............................................................................ 140

13.1 Residual moisture control....................................... 140

13.1.1 Function description of residual moisture control 140

13.1.2 Residual moisture control operating mode.......... 140

13.1.3 Setup menu for residual moisture control............ 141

13.1.4 Calibrating the residual moisture control system. 141

13.2 Heat recovery......................................................... 141

13.2.1 Function description of the heat recovery

system................................................................. 141

13.2.2 Technical data of the heat recovery system......... 142

13.3 Automatic unloading station.................................... 143

13.3.1 Function description of the automatic unloading

station.................................................................. 143

13.3.2 Setup menu for the unloading station.................. 143

13.3.3 Technical data of the unloading station................ 144

13.4 Cuff tuck press........................................................ 145

13.4.1 Function description of the cuff tuck press.......... 145

13.4.2 Setup for the cuff tuck press................................ 145

Table of contents

18.07.2017

Shirt finisher VEIT SF26

4