MA-AL-T73E-01-03 Manual TUL373EN eng rev3 Rev.3 Page 1 of 4

POWER SUPPLY TUL373 EN

CERTIFIED UNI EN54-4:2007. Included updating A1:2002 and A2:2006

Installation Manual

GENERAL FEATURES

The power supply TUL 373 EN has been designed to be used as power unit with energy stock in the fire security systems in conformity

to regulation (EU) No 305/2011.

Its electrical and mechanical features make it be conform to the norm EN 54-4:1997 + A1:2002+A2:2006 (Systems for detection and

fire indication: Part 4: supplying devices).

FUNCTIONAL FEATURES

The power supply unit is made by a linear power supply, series adjustment, with serial voltage regulator, limited in constant precision

current (rectangular limitation), two 12V 17 Ah batteries (not given within) analogical control circuit and micro-controlled supervision

circuit.

Supplying is divided on 3 terminal-outputs protected by fuses:

BAT: where the back-up battery will be connected

OUT 1 and OUT2: for generic charges

The charge of the battery occurs at constant tension (27,6 V @ 25°C) with temperature compensation and current limitation.

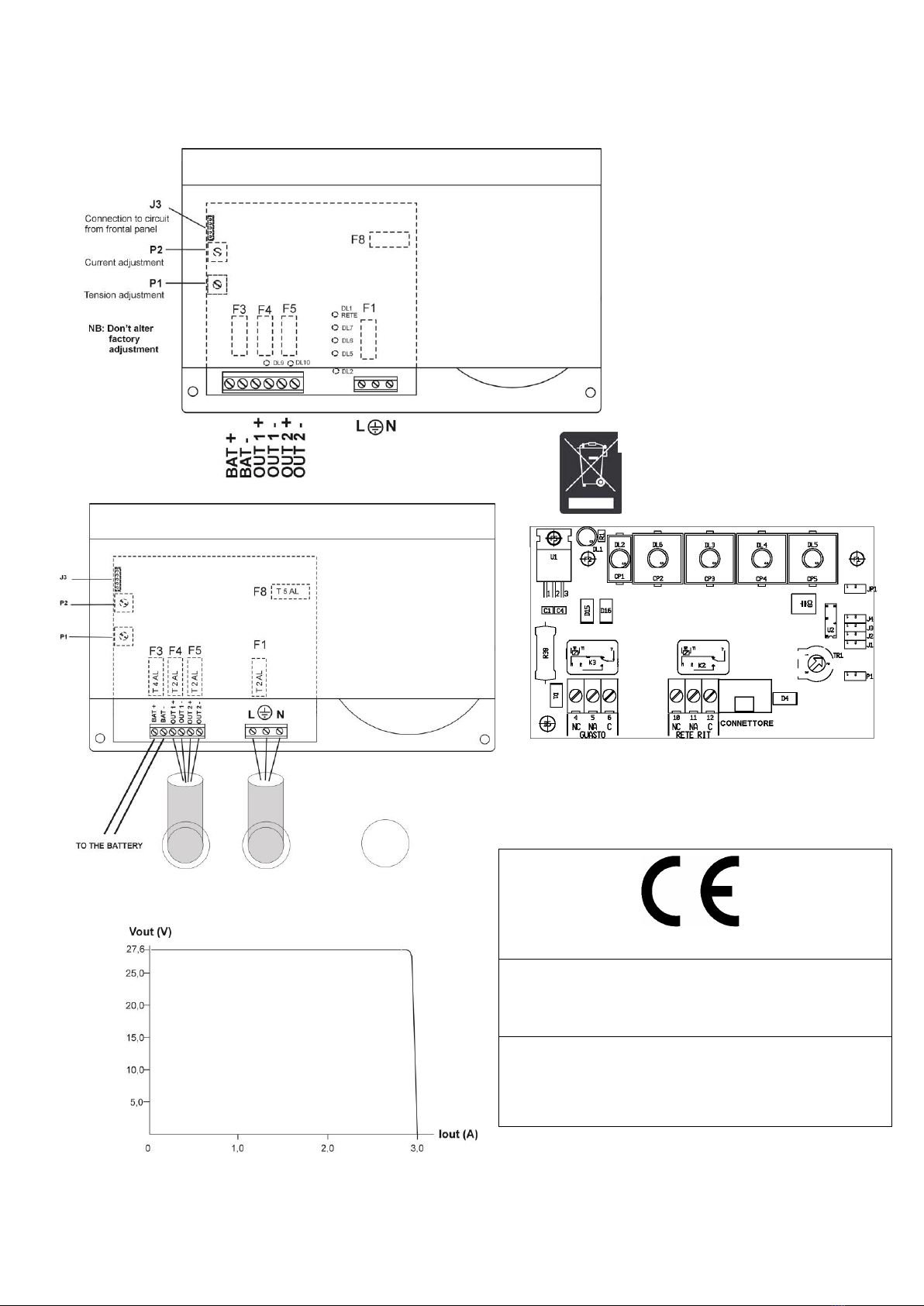

The maximum current supplied by the power supply is 3 A with 2 A for charge and 1 A for the battery.

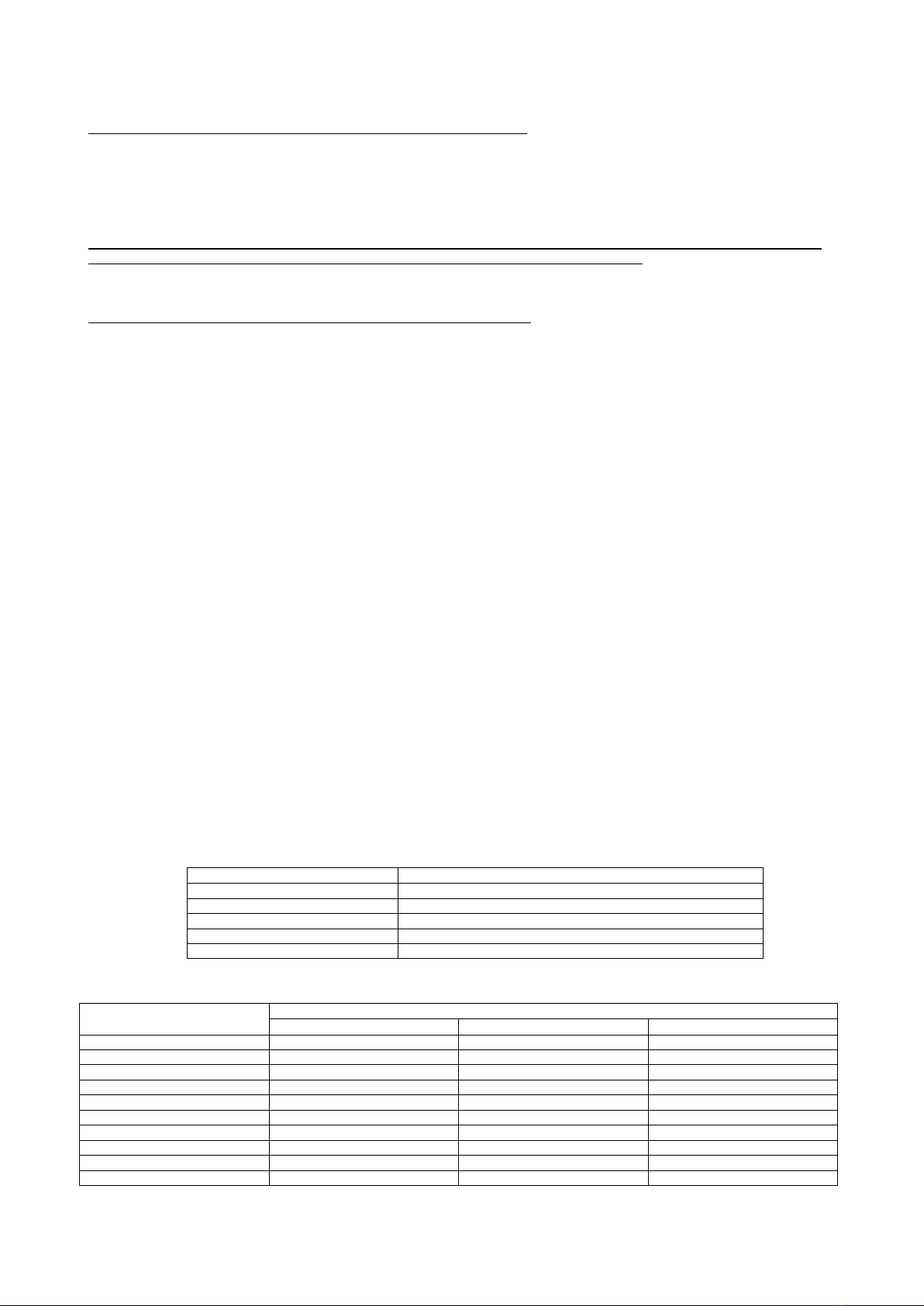

The LED on the control board are close to concerned fuses (see pict.1) and show:

-Fuse cut for any of the outputs, with Led off (DL9, DL10)

-Current consumed by charge (2 green and one red DL5, DL6, DL7)

-Mains presence (DL1 RETE)

Check of battery efficiency

The power supply periodically carries out the efficiency of the batteries:

At first activation of the power supply , the microprocessor will carry out the test of battery presence after about 30 seconds. If

connected, the test will be carried out every 10 minutes whilst in case it is not connected, it will continue carry out the test every 20

seconds showing indication FAILURE.

During normal functioning, the efficiency of the battery is checked by controlling the batteries tension. If batteries do not manage to

maintain an acceptable tension during test, there will be the indication FAILURE.

A test of the internal resistance of the battery is carried out during normal functioning, every 1,5 hours (in conformity to attachment

EN54-4/A2); if the internal resistance is over 1 ohm, there will be a FAILURE indication. It will then be necessary to replace the

batteries and check that terminals and fuses have a good electrical contact. When the battery is replaced, with presence of mains

tension, the test of internal resistance is repeated every 5 minutes.

A microcontroller system controls various possible anomalies and gives a FAILURE indication in the following conditions:

1. Output Fuses interruptions

2. Overloaded Battery (> 30 V)

3. Low Battery Tension (< 21 V)

4. Power absence and no battery charge

5. Disconnected Battery

6. Internal battery resistance >1 Ώ

The indication of failure together with the indication of mains absence are in a connector placed on the control and supervision board.

In order to avoid that a possible failure in the series regulator damages the charges or the battery, a protection circuit has been inserted

against over-tensions, made of a SCR and a fuse. A fuse for mains alternated supplying is also present.

In case of failure in the power supply or of mains missing, supplying of the logic and control circuits occurs by means of battery.

.

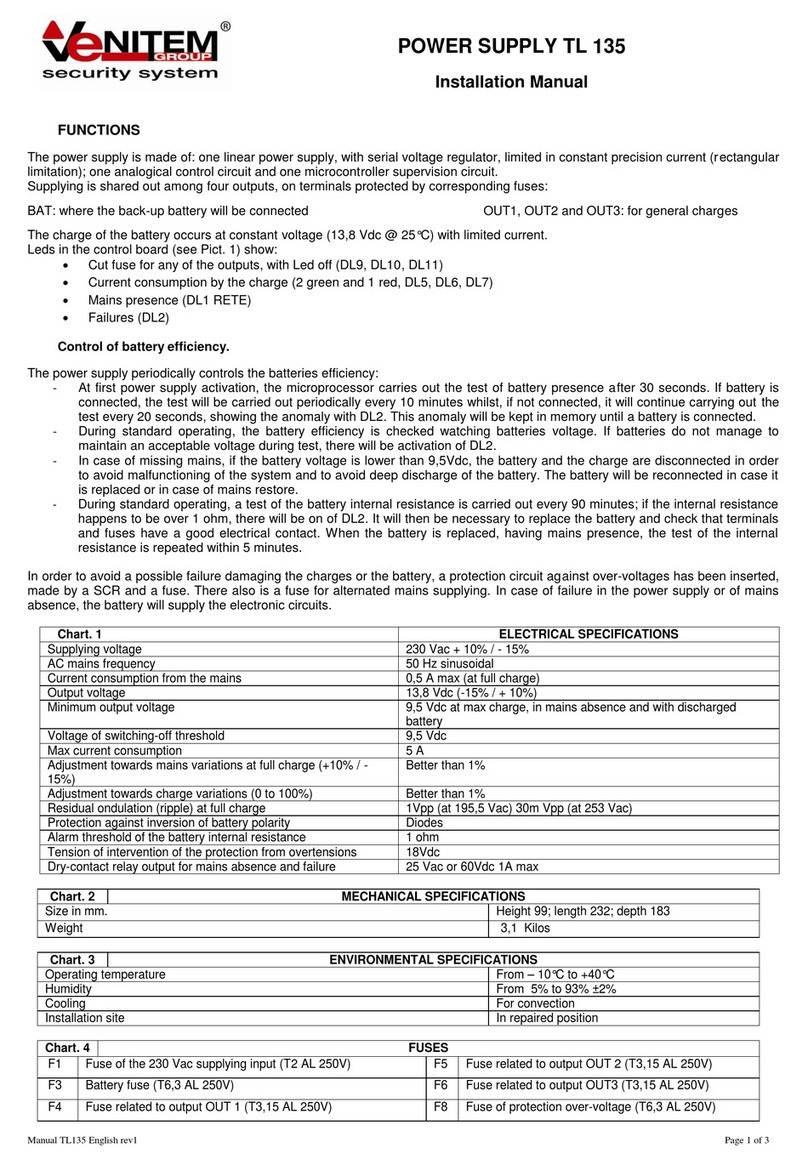

Electrical Specifications

Current consumption by mains

20 Vdc at max charge, with mains absence and battery

discharged

Switching-off threshold tension

Max current for battery recharge

Regulations towards mains variations at full charge (+10% / -15%)

Regulations towards charge variations (0 to 100%)

1 Vpp ( at 195,5 Vac ) 30mVpp ( at 253 Vac )

Compensation of output tension according to temperature

Protection against battery polarity inversion

Recommended batteries: 2 x 12 V in series, 17 Ah housing with

inflammability class UL-94-V2 or better

Type:YUASA NP 17-12 or equivalent.

Alarm threshold of battery internal resistance

Missing mains and failure output relay –dry contacts