2

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the following:

GENERAL INFORMATION . . . . . . . . . 3

TOOL LISTING . . . . . . . . . . . . . . . . . . . . .3

WORKING WITH PLASTIC TUBING. . . . . . . . . . . . . 3

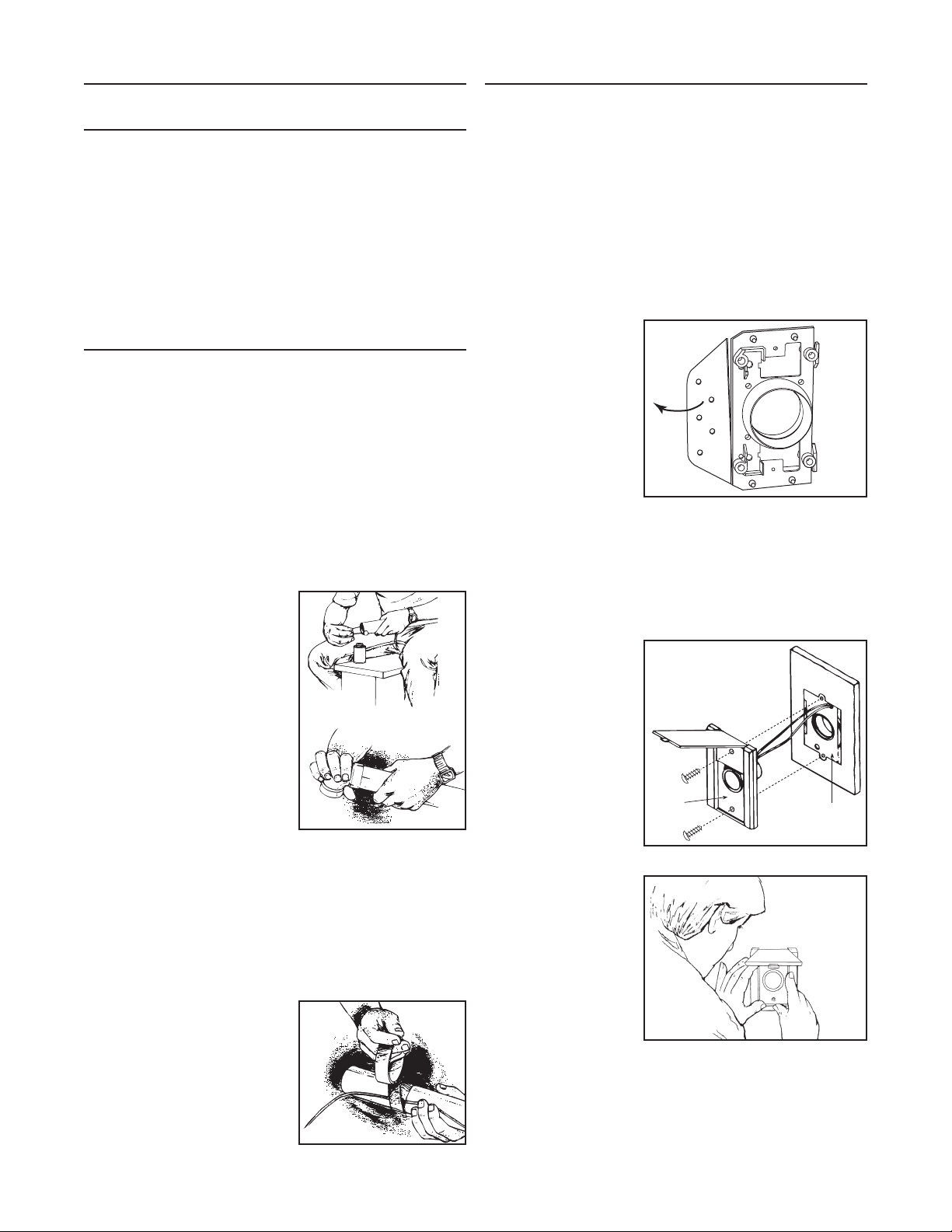

WALL INLET INSTALLATION . . . . . . . . 3

V600W VACUSWEEP®

INLET VALVE INSTALLATION . . . . . . 4-6

CONNECTION FROM BELOW . . . . . . . . . . . . . . .4

CONNECTION FROM BEHIND . . . . . . . . . . . . . . .5

CONNECTION IN AWALL . . . . . . . . . . . . . . . .6

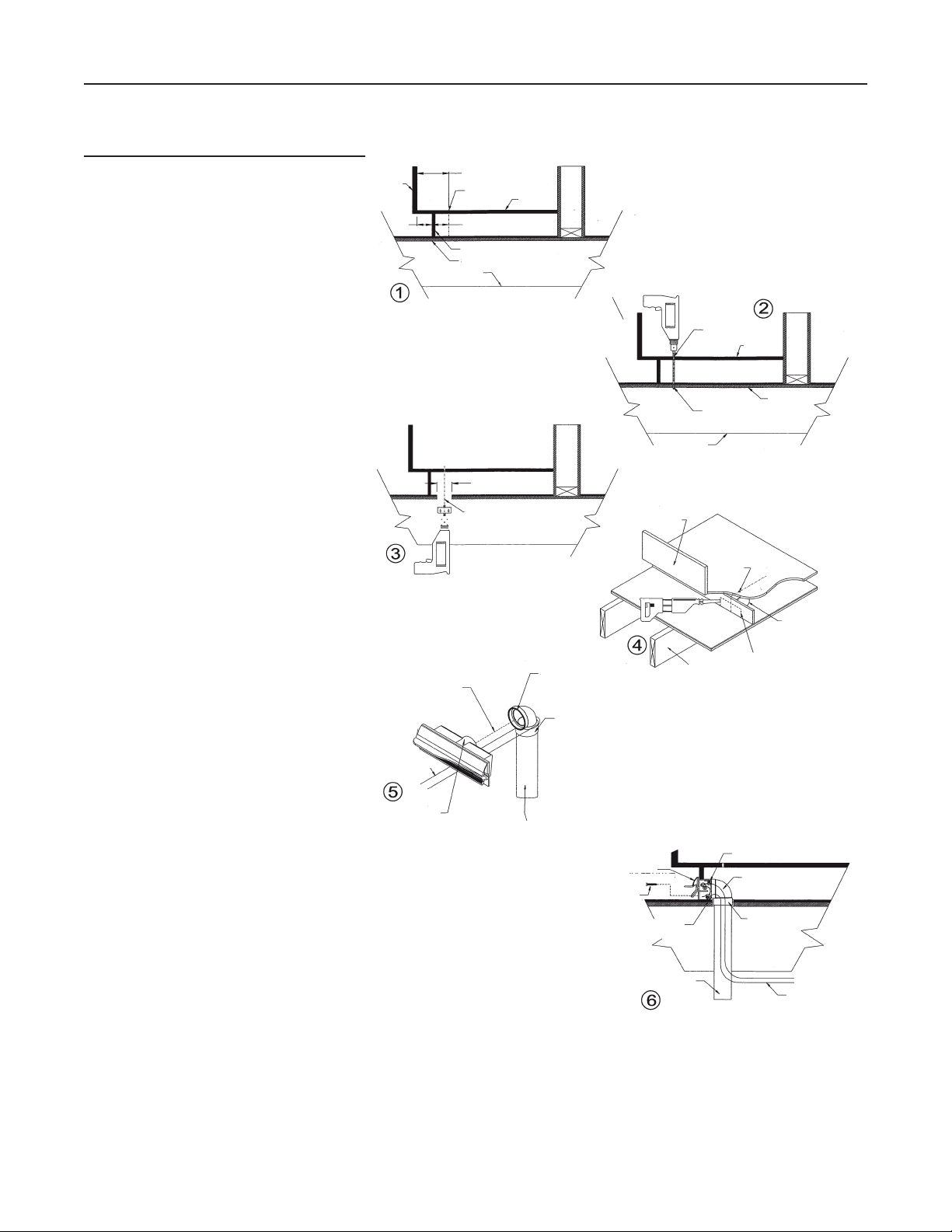

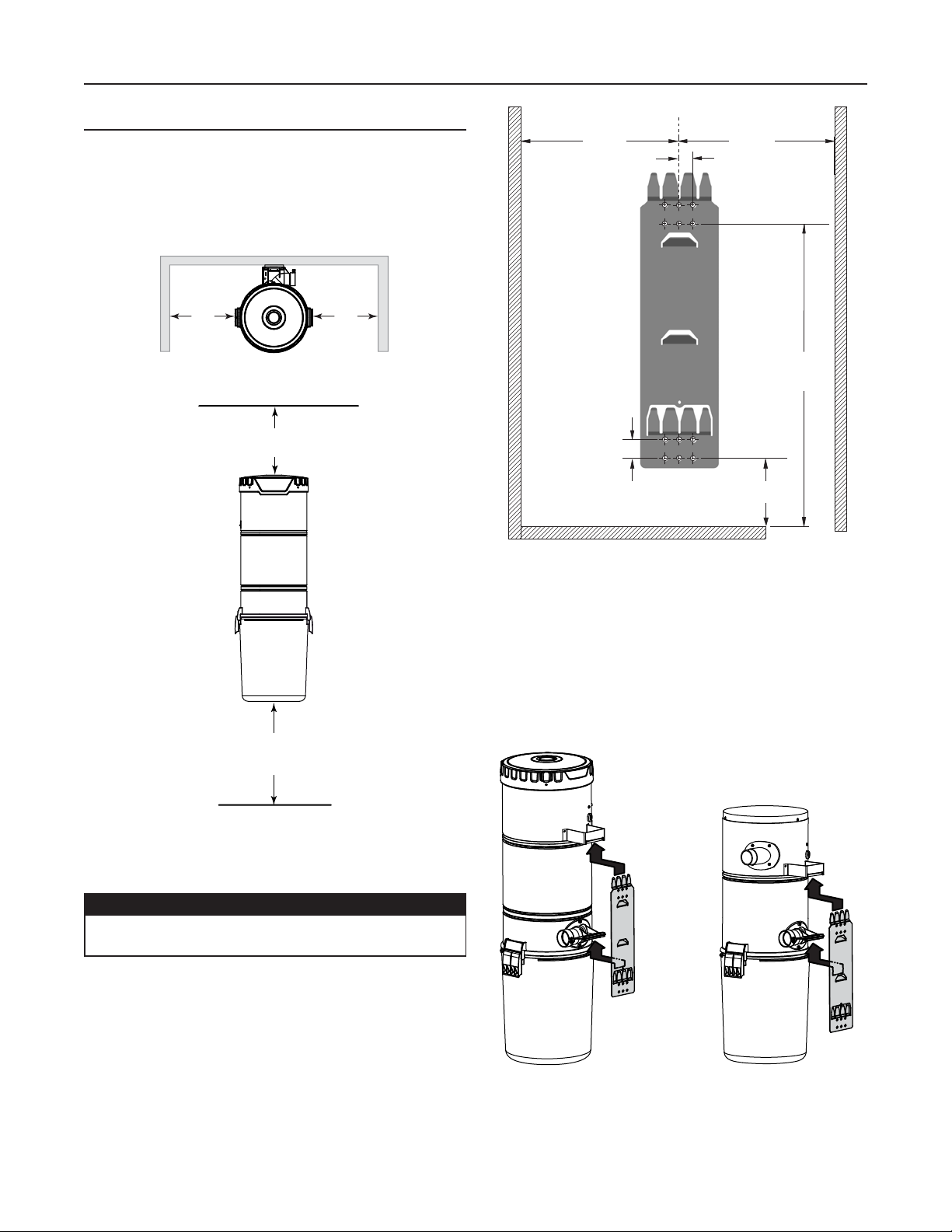

POWER UNIT INSTALLATION . . . . . . 7-9

LOCATING THE POWER UNIT . . . . . . . . . . . . . .7

CHANGING INTAKE LINE DIRECTION . . . . . . . . . . .7

MOUNTING THE POWER UNIT . . . . . . . . . . . . . .8

FITTING MAIN LINE TO POWER UNIT . . . . . . . . . . .9

GROUNDING INSTRUCTIONS . . . . . . . 9

WIRING . . . . . . . . . . . . . . . . . . . . . . . .9

OPERATION AND MAINTENANCE . . .10-11

WHEN TO CHANGE BAG OR EMPTY DEBRIS PAIL . . . . 10

HOW TO EMPTY DEBRIS PAIL

(600VF AND 650VF POWER UNITS ONLY). . . . . . . 10

DISPOSABLE BAG REPLACEMENT

(500VF POWER UNIT ONLY) . . . . . . . . . . . . . 10

PERMANENT FILTER

(600VF AND 650VF POWER UNITS ONLY). . . . . . . 10

REMOVAL AND INSTALLATION OF PERMANENT FILTER

(600VF AND 650VF POWER UNITS ONLY). . . . . . . 10

REMOVAL AND INSTALLATION OF HEPA FILTER

(650VF POWER UNIT ONLY) . . . . . . . . . . . . . 11

MOTOR FOAM FILTER (ALL UNITS) . . . . . . . . . . . 11

TROUBLESHOOTING GUIDE. . . . . . . 12

SERVICE PARTS . . . . . . . . . . . . . 13

WARRANTY . . . . . . . . . . . . . . . . 14

TABLE OF CONTENTS

WARNING

To reduce the risk of fire, electric shock or injury:

1. Do not use on wet surfaces or outdoors.

2. Do not vacuum liquids or fine powders (such as drywall dust).

3. Do not use to pick up flammable or combustible liquids such

as gasoline or use in areas where they may be present.

4. Do not pick up anything that is burning or smoking, such as

cigarettes, matches, or hot ashes.

5. Do not allow to be used as a toy.Close attention is necessary

when used by or near children.

6. Use only as described in this manual. Use only

manufacturer's recommended attachments.

7. Keep hair, loose clothing, fingers and all parts of body away

from openings and moving parts.

8. Turn off all controls before unplugging.

9. Use extra care when cleaning on stairs.

10. Do not handle plug or appliance with wet hands.

11. Do not use with damaged cord or plug. If appliance is not

working as it should, if it has been dropped, damaged,

left outdoors, or dropped into water, return it to a Service

Center.

12.Keep your work area well lighted.

13.Connect to a properly grounded outlet only. See grounding

instructions shown on page 9.

14.When performing installation, servicing or cleaning the unit,

it is recommended to wear safety glasses and gloves.

15.When applicable local regulations comprise more

restrictive installation and/or certification requirements,

the aforementioned requirements prevail on those of this

document and the installer agrees to conform to these at

his own expenses.

CAUTION

1. Do not put any object into openings. Do not use with any

opening blocked; keep free of dust, lint, hair and anything

that may reduce air flow.

2. Ensure air flows freely and exhausts unobstructed from top

or side outlet.

3. Do not use without filter (or filters, according to the model)

in place.

4. Do not use to blow leaves or debris.

5. Do not place any object on top of the unit.

6. Do not install the unit horizontally.

7. Do not use the pail as a wash bucket.

8. Do not use the pail as a stool.

9. Avoid picking up sharp objects.

10. This appliance is for use on a standard 120 VAC, dedicated

15-amp branch circuit.

11. Do not unplug the unit by pulling on cord. To unplug, grasp

the plug, not the cord.

12.Store your vacuum cleaner indoors in a clean, dry area, and

away from extreme temperatures.

13.Any servicing other than that recommended in this manual

should be performed by an authorized service facility.

14.We recommend that your unit be inspected by a specialized

technician once a year.

!