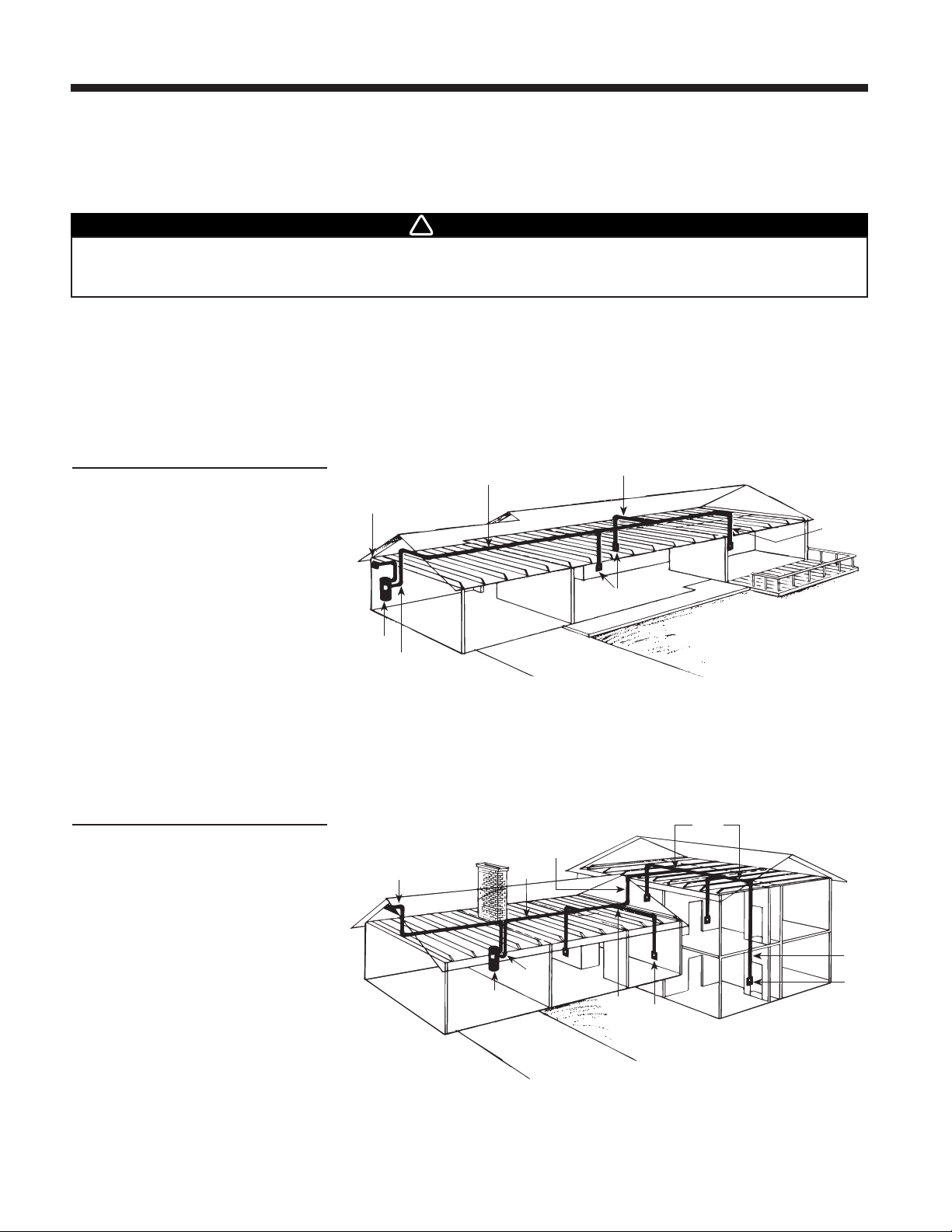

Use the following procedures for installation in existing

construction. Wall inlets in existing construction may be

accessed from below (basement or crawl space) or from

above (attic). Instructions apply to either method.

Starting from farthest wall inlet location, install each inlet as

described below. Working back toward power unit, connect

each inlet line and branch line into main trunk line. See pages

2 and 3. Complete low-voltage wiring as main trunk line is

continued back to power unit. Mount power unit and complete

wiring. See pages 18 and 19.

LOCATING ACCESS KEYS

IN EXISTING CONSTRUCTION

Unless your home is a ranch-style house where a single trunk

line can run directly through the attic or basement, you should

first investigate your house to find the key to running your

tubing from level to level. Look for an accessible area free

from obstructions that will accommodate the 2" (51 mm) tubing.

If you understand how your existing home is constructed, it

can be relatively easy to find access routes to run the tubing.

Refer again to the illustrations on pages 2 and 3 as you

consider your home construction.

Some of the keys you might find in your home are illustrated

here.

Stacked Closets or Laundry Chute

Many homes will have an upstairs closet located directly

above a downstairs closet. It is easy to run the tubing from

one floor level to another inside these stacked closets. In

these installations the tubing is often left exposed inside the

closets. Refer to Figure 19. A laundry chute could also provide

access from basement to upper floors. You may also want to

consider running exposed tubing through cabinets or cupboards.

AVOIDING IN-WALL OBSTACLES

The tubing which connects the inlet into the trunk line is

threaded through interior partition walls. After you’ve chosen

an inlet location, make sure the wall doesn’t contain some

hidden obstacle which will prevent you from running tubing to

the inlet.

Exterior Walls. The insulation in these walls will prevent you

from running tubing through them.

Electrical Wiring. Wiring may not obstruct your tubing, but you

should always make sure that tubing does not damage the

wiring. Electrical outlets and wall switches are signs of wiring.

Ductwork. Avoid choosing a section of wall that contains

ducting. If you see signs of ductwork—such as floor or ceiling

registers—move your inlet location to another section of the wall.

Plumbing. Plumbing may or may not prevent you from

running tubing through a wall. If you must choose a plumbing

wall for an inlet location, be extremely careful when making a

cutout in the wall.

Wall Studs. Make sure your location is between wall studs.

Locate studs by tapping walls, looking for electrical outlet

(usually fastened to studs), or noticing finishing nails in the

floor molding.

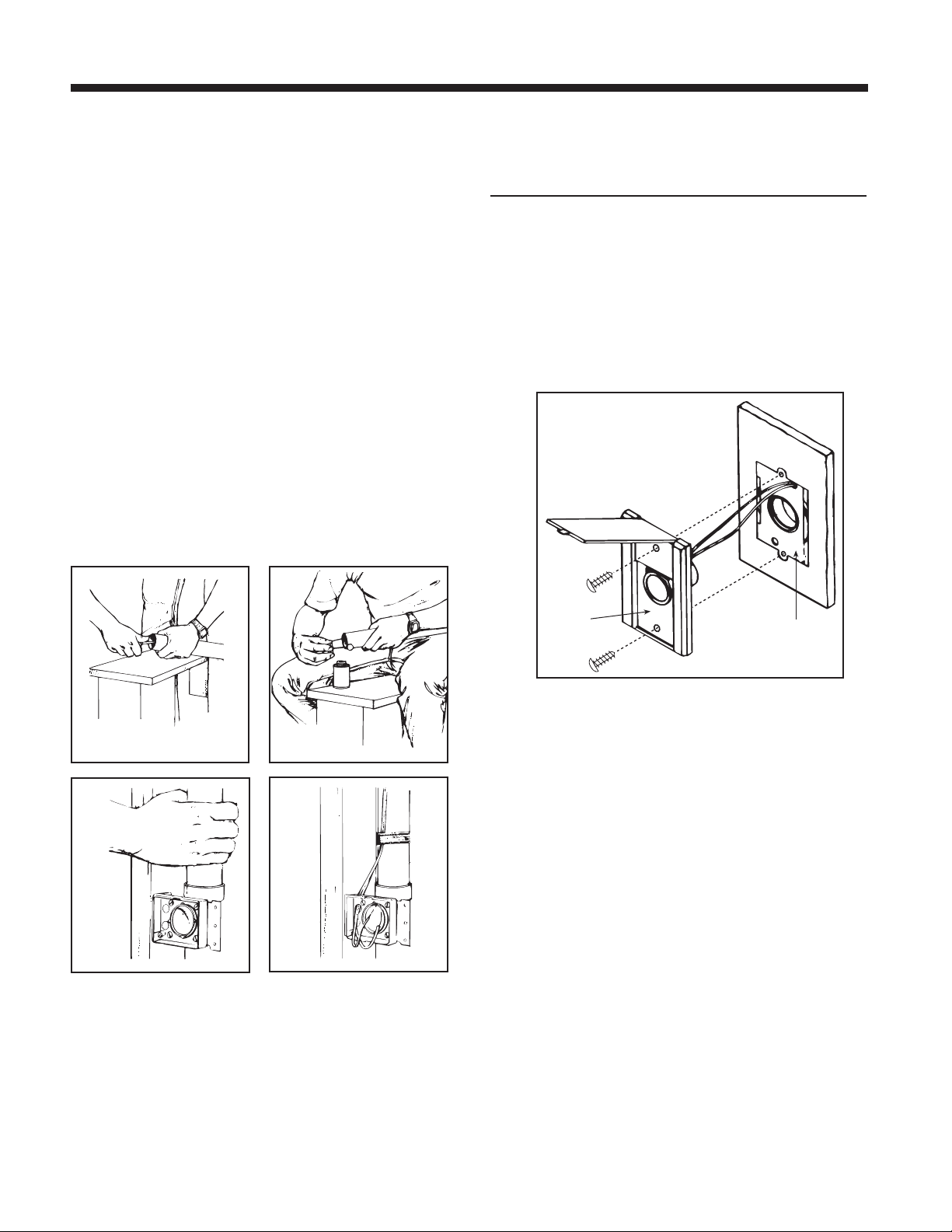

INLET TUBING INSTALLATION

When your planning is complete, you will have to determine

where all the inlets and the power unit will be located. You

have mapped out the location of your trunk line and found the

access you need to run vertical tubing from one level of your

house to another level. You should have acquainted yourself

with the methods of joining plastic tubing and acquired the

tools you will need to install your Broan or NuTone Central

Vacuum System. Now, you can begin installation.

The first step is to install the inlet tubing which connects the

wall inlets to the branch lines. As explained before, the inlet

lines run inside interior walls. You will find access to these

walls through your attic or basement. Briefly, you want to find

the exact location in the wall, drill an access hole through the

wall plate or header, and insert the tubing into the wall cavity.

This part of your installation requires close observation and

careful measurements. Take your time and make sure you

accurately line up your access holes with the locations you’ve

chosen for your wall inlets.

Locating Attic Access Holes

Drill the access holes directly above the inlet location.

To accurately locate the access hole, you must find the space

between wall studs where the inlet is to be located. Observe

the area around the inlet location. Look for references you

might be able to find in the attic: electrical wiring, ductwork,

doorways, etc. Measure and note the distance from these

references to the inlet location.

page 7

INSTALLATION IN EXISTING CONSTRUCTION