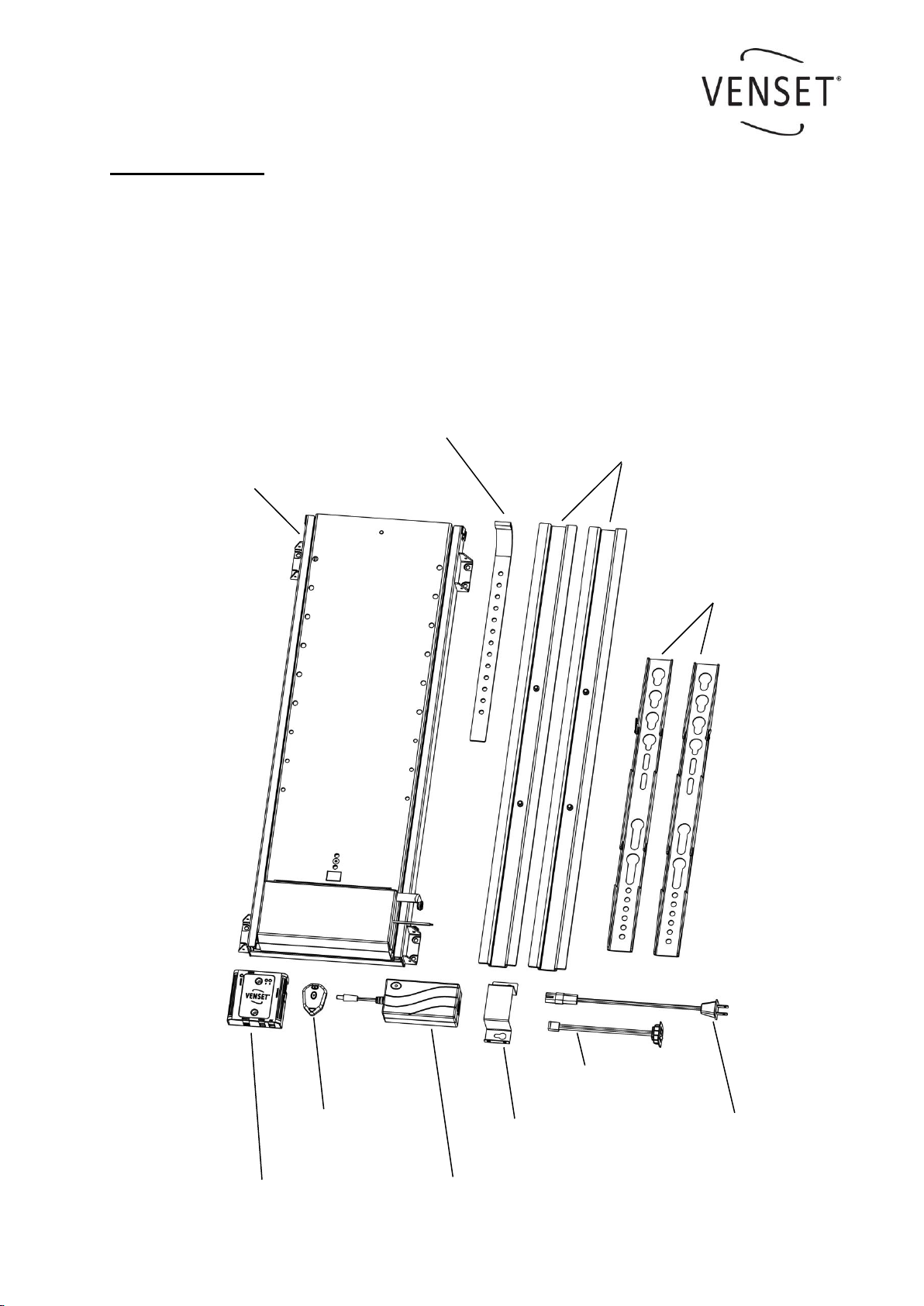

Electric TV Lift, TS700C & TS1000C

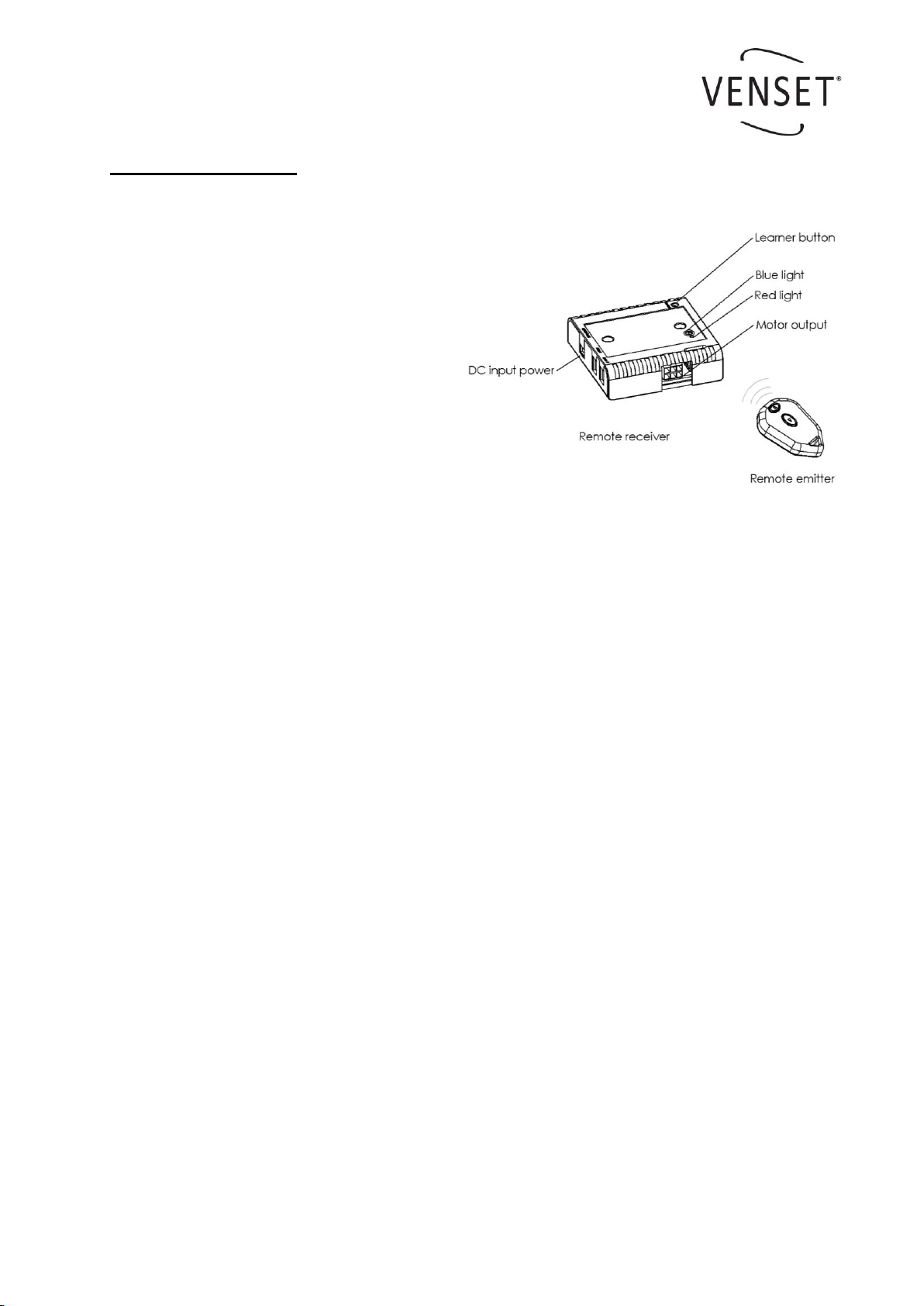

5. RF remote system.

Installation

oconnect the power supply and

the motor unit to the remote re-

ceiver. 2 different plug sizes

make this connection only possi-

ble to make in the right way

oafter having connected the plugs,

the blue light will be lit

opush the emitter buttons and the

motor unit will move up and down

ofor stopping the motion one of the

buttons need to be pushed again

Learning

oif the remote receiver does not respond when pushing the emitter buttons, reset the

receiver. After that, code the emitter and receiver together again.

oit is possible to code up to 10 remote emitters to the remote receiver.

Coding

opush the learner button on the receiver for less than 1 sec.

opush one of the emitter buttons

othe red light will start flashing

opush one of the emitter buttons again and the red light will turn off

othe units now are coded together with a unique code

Reset

opush and hold down the learner button on the receiver for 10 sec. (will be reset when

the red light start to blink).

External rocker switch

othe external rocker switch #9 can be connected to the receiver, if a fixed operation

unit is required. This should always be fitted or accessible in case the RF handset or

battery fails.

Trouble shooting

ocheck the plug connections

ocheck whether the blue light is on

oreset the receiver and make a new coding

oalways test the lift on the manual rocker switch

osee www.venset.com , click “support”