5

INTRODUCTION

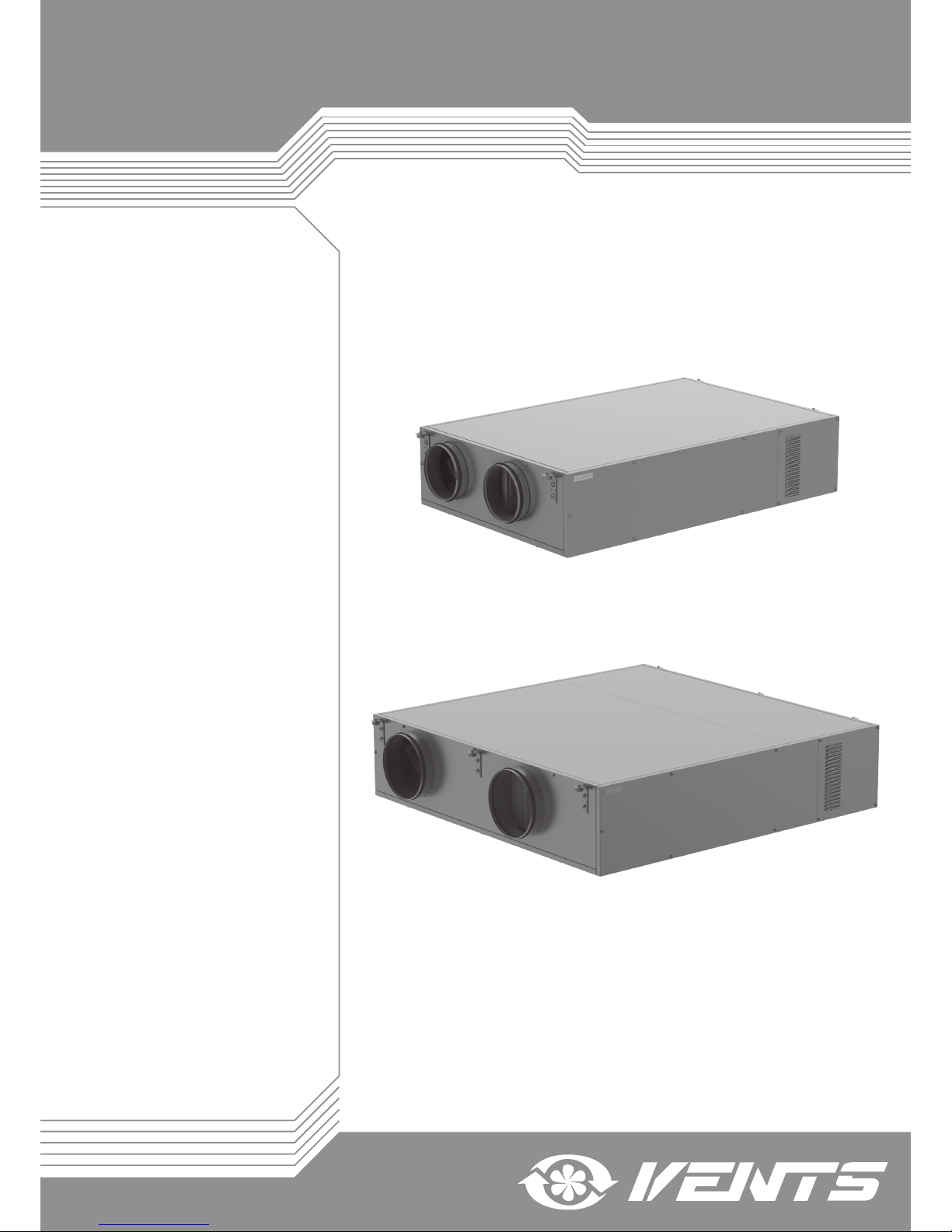

This user’s manual includes technical description, operation, installation and mounting guidelines, technical data for the heat recovery air

handling unit VENTS VUT 600-1000 PW EC, hereinafter referred to as «the unit».

USE

THE UNIT IS NOT INTENDED TO BE USED BY CHILDREN, PHYSICALLY OR MENTALLY DISABLED PER

SONS, PERSONS WITH SENSORY DISORDER, PERSONS WITH NO APPROPRIATE QUALIFICATION.

ALL OPERATIONS WITH THE UNIT MUST BE PERFORMED ONLY BY PROPERLY QUALIFIED PERSON

NEL AFTER THE APPROPRIATE SAFETY BRIEFING.

THE UNIT INSTALLATION SITES MUST PREVENT ACCESS BY UNATTENDED CHILDREN.

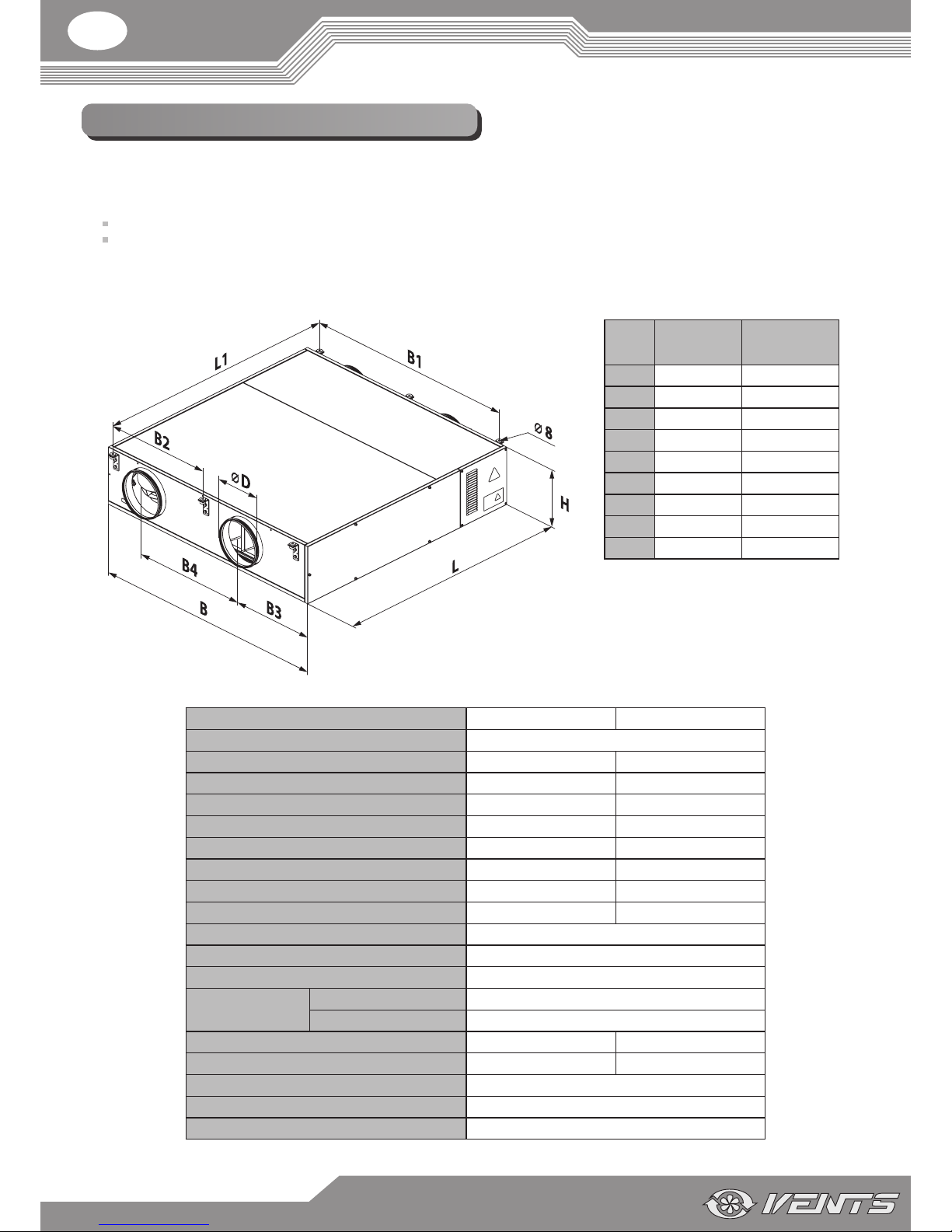

DELIVERY SET

Name Number

Unit

1 item

User's manual

1 item

Control panel

1 item

Packing box

1 item

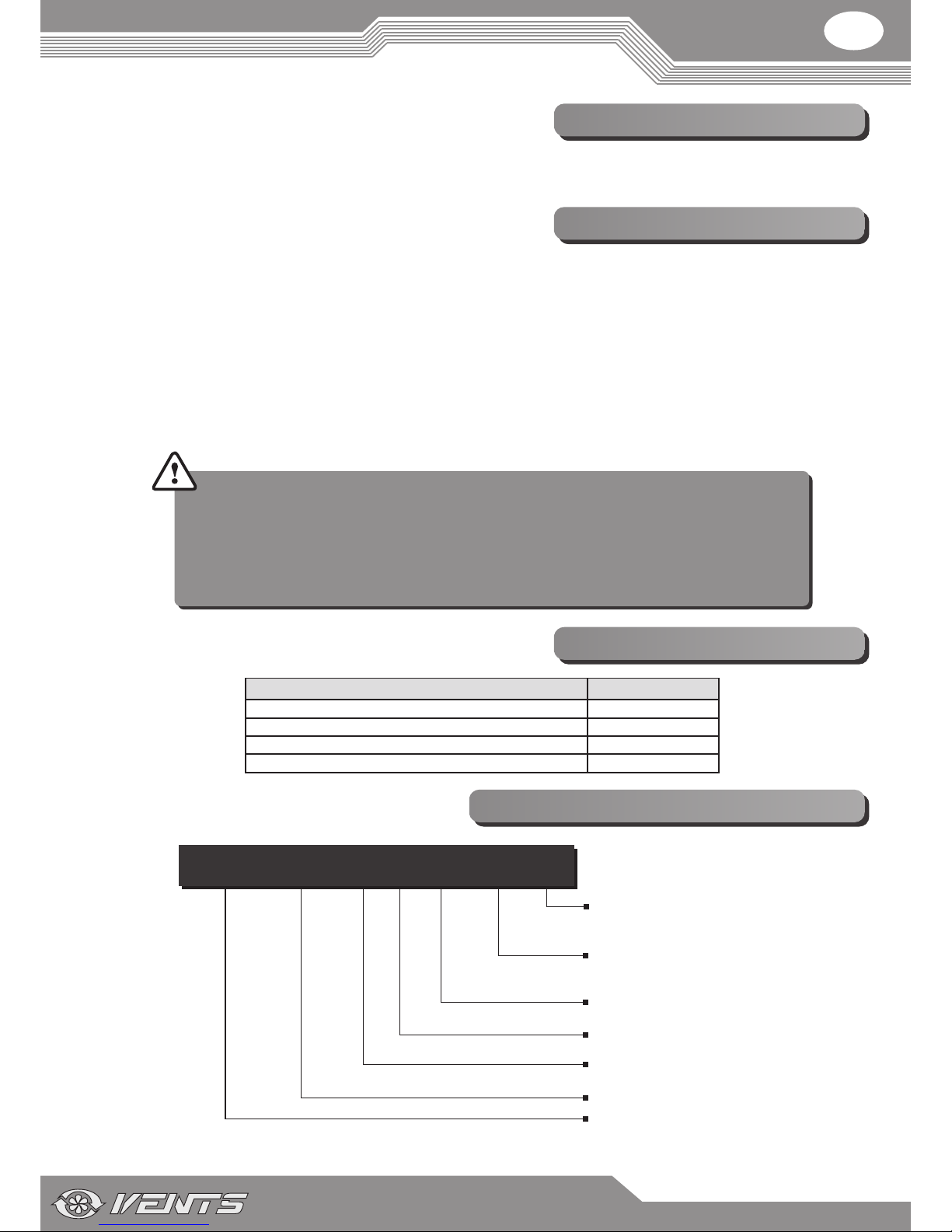

Service side

L - left

R - right

Motor type

EC - electronically commutated

Heater type

W - water heater

Unit type

VUT - ventilation with heat recovery

Mounting method

P - suspended mounting

Air capacity [m /h]

Control panel

_ - PU SENS 01 with a sensor display

A7 - PU JK 01 with an LCD display

VUT ХХХ P W ЕС - Х - X

3

DESIGNATION KEY

The unit with heat recovery and a water heater is designed to save heat energy by means of heat recovery and is one of the energy saving

components used in the buildings and premises. The unit is a component part and is not designed for independent operation.

The unit is designed to provide permanent controlled air exchange by means of mechanical ventilation in houses, oces, hotels, cafés,

meeting halls and other mechanically ventilated premises as well as utilization of extract air heat energy to warm up supply puried air.

The unit is designed for suspended mounting.

The unit is designed for extended periods of continuous operation without disconnection from power mains.

Transported air must not contain any ammable or explosive mixtures, evaporation of chemicals, sticky substances, brous materials,

coarse dust, soot and oil particles or environments favourable for the formation of hazardous substances (toxic substances, dust, pathogenic

germs).