VRG VERACHTERT

07.02 all rights reserved

3

C O N T E N T S

page

1. PRODUCT IDENTIFICATION..................................................................................................................4

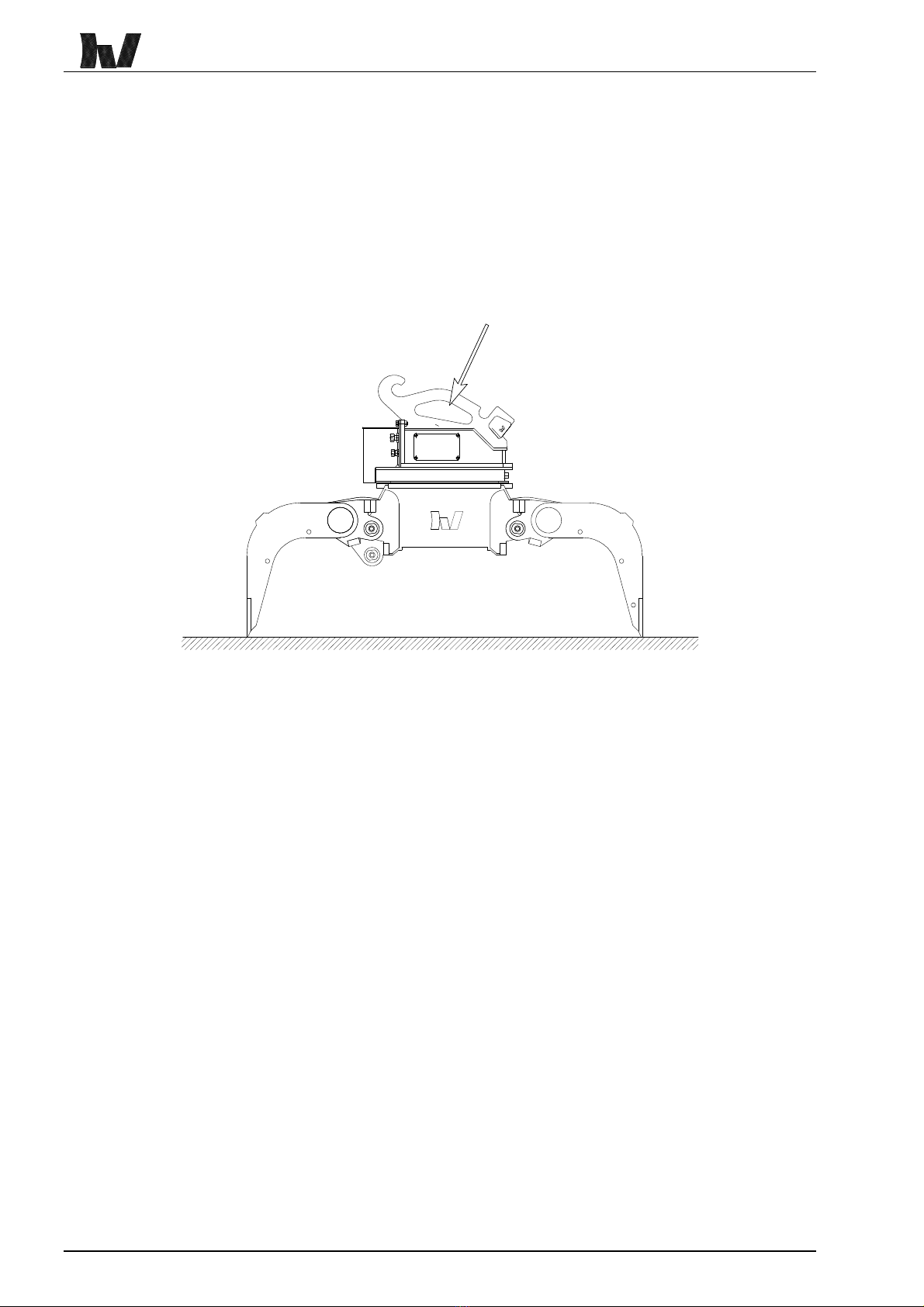

2. HOISTING THE VRG GRAB ...................................................................................................................6

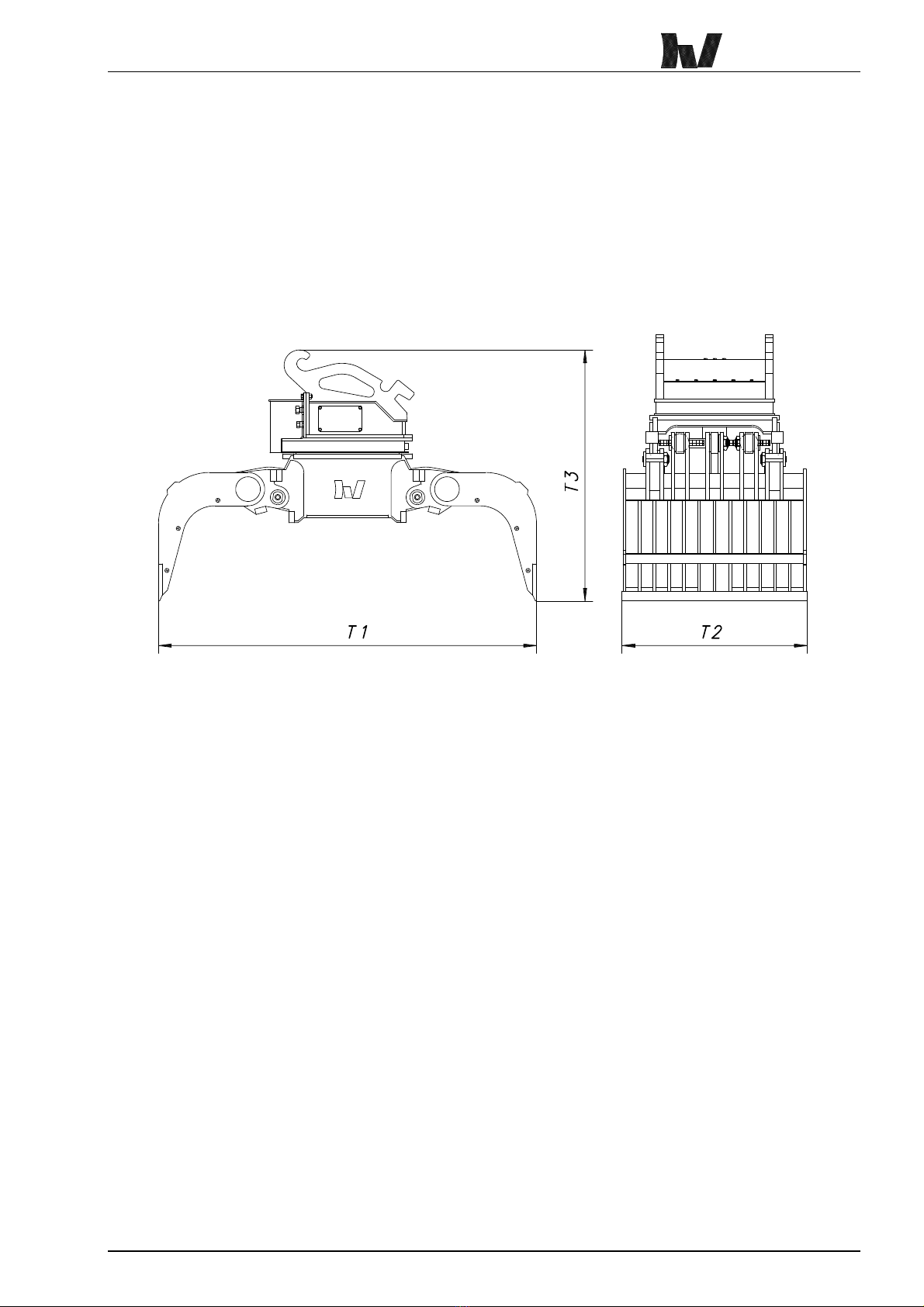

3. PRODUCT OVERVIEW AND TECHNICAL SPECIFICATIONS.............................................................7

3.1 VRG-GRAB MODELS.............................................................................................................................8

3.2 OPTIONS AND CODES ...........................................................................................................................9

3.3 TECHNICAL DATA................................................................................................................................10

3.4 CALCULATING THE EXCAVATOR/EQUIPMENT COMBINATION ...................................................................11

4. INSTALLING THE VRG GRAB .............................................................................................................13

4.1 HYDRAULIC COUPLERS .......................................................................................................................14

4.2 MOUNTING THE VRG GRAB TO THE EXCAVATOR ..................................................................................17

4.3 VENTING THE HYDRAULIC SYSTEM.......................................................................................................18

4.4 MEASURING WORKING PRESSURES AND OPENING AND CLOSING TIMES..................................................19

5. OPERATION ..........................................................................................................................................21

6. THE APPLICATION OF LOADING AND BREAKING PLATES ..........................................................23

7. MAINTENANCE AND REPAIR .............................................................................................................25

7.1 SAFETY PRECAUTIONS .......................................................................................................................26

7.2 DAILY MAINTENANCE ..........................................................................................................................28

7.3 WELDING THE VRG GRAB ..................................................................................................................29

7.4 REPLACING REMOVABLE EDGES ..........................................................................................................29

7.5 TORQUE VALUES FOR METRIC THREAD JOINTS .....................................................................................29

8. HYDRAULIC DIAGRAM........................................................................................................................30

9. SPARE PARTS......................................................................................................................................32

WARRANTY CONDITIONS........................................................................................................................33

INFORMATION SHEET ..............................................................................................................................35