2.0 Installation

Using the tube furnace horizontally

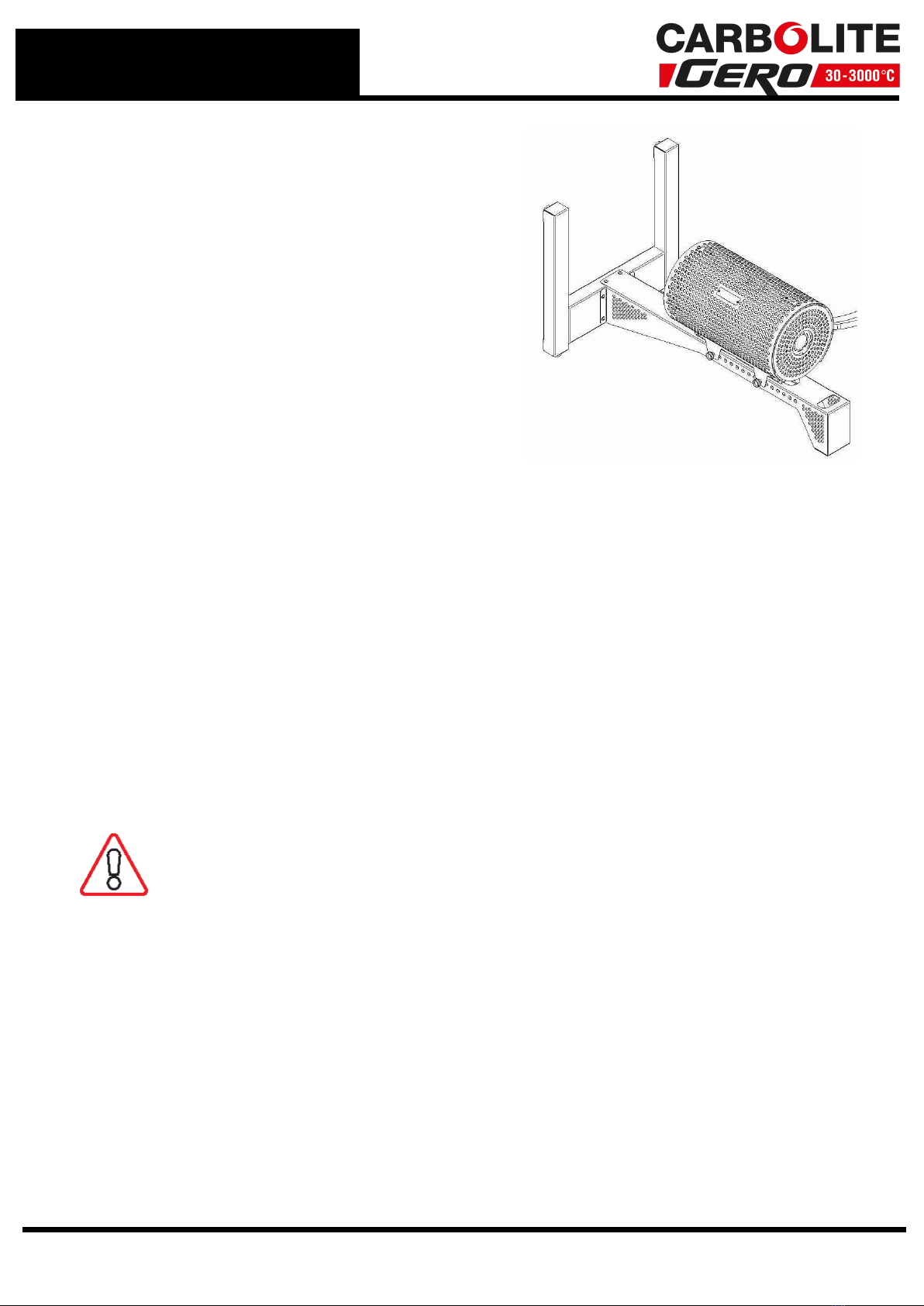

The furnace can be used either with the stand

vertically as shown in 2.3.3 or horizontally as

shown in 2.3.4.

To use horizontally simply tip the stand over

into the horizontal position making sure that

the flexible conduits are not trapped beneath

the frame. This may take 2 people to do on

the largest models.

The position of the furnace on the stand can

be adjusted if necessary.

Note: To prevent injury to the operator and

damage to the furnace this must only be

done when the furnace is switched OFF and is

cold. 2.3.4 Figure -Tube furnace posi-

tioned horizontally on the stand.

Note that the split tube furnace can only be used with the extended length work tube.

Fitting the extended work tube in a furnace

Tools required: 4 mm Allen key

The fitting of the work tube is as follows with reference to Figure 2.3.8. Extended work

tubes are 450 mm longer than the heated length of the furnace (see the table in section

10.0). Read section 6.2 before fitting the work tube.

Note it is easier to fit the work tube with the furnace in the horizontal position as shown

in figure 2.3.4.

To fit the work tube in a vertical orientation follow the steps below. Omit the use of the

end seal if not required. The same tube support design will work with or without the

tube end seal in place.

WARNING - If clamps are used without an end seal, care should be

taken not to over tighten on to a bare tube, especially if the tube is

either quartz or thin wall thickness.

lBefore the extended work tube can be fitted, the work tube end stops for the stand-

ard length work tube must be removed from both ends of the furnace. This is done

by removing the tube furnace end guard (8) and the work tube adaptor brackets (4)

to release the work tube end stop. The guards and brackets should then be refitted.

lFit the tube support bracket, item 15, figure 2.2. Use supplied M6 button head

screws and supplied washers.

lFit the extended work tube guard, item 14, figure 2.2. Use supplied M6 button head

screws and supplied washers.

lRe-fit furnace end guard, item 13, figure 2.2. Use supplied M6 button head screws

and washers.

lFit tube end seal assembly as shown in figure 2.2. refer to manual that was provided

with the replacement end seals or detailed fitting instructions.

10