VERDER Packo ZP Series User manual

Other VERDER Water Pump manuals

VERDER

VERDER HI-CLEAN VA-H20 User manual

VERDER

VERDER Verderflex Vantage 3000 C Series User manual

VERDER

VERDER VERDERAIR VA-EH50 Instruction Manual

VERDER

VERDER VERDERAIR VA 25 Operation manual

VERDER

VERDER AIR VA 25 Operation manual

VERDER

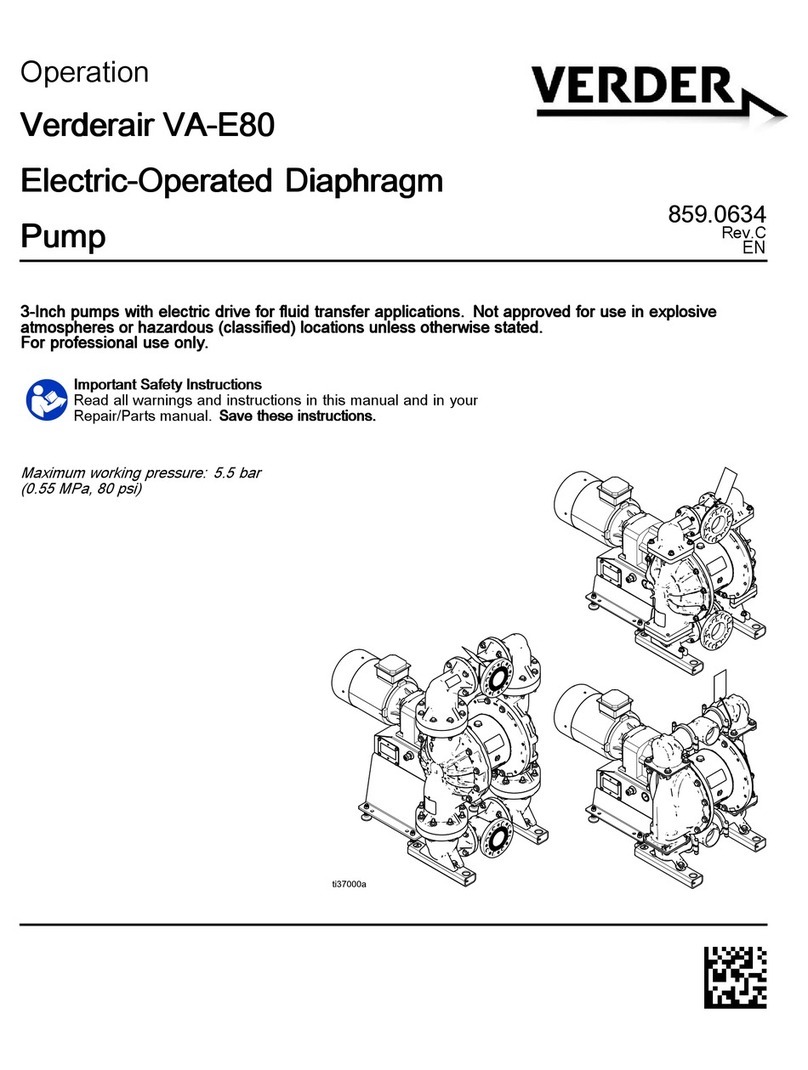

VERDER Verderair VA-E80 Instruction Manual

VERDER

VERDER VERDERAIR E-PURE ATEX User manual

VERDER

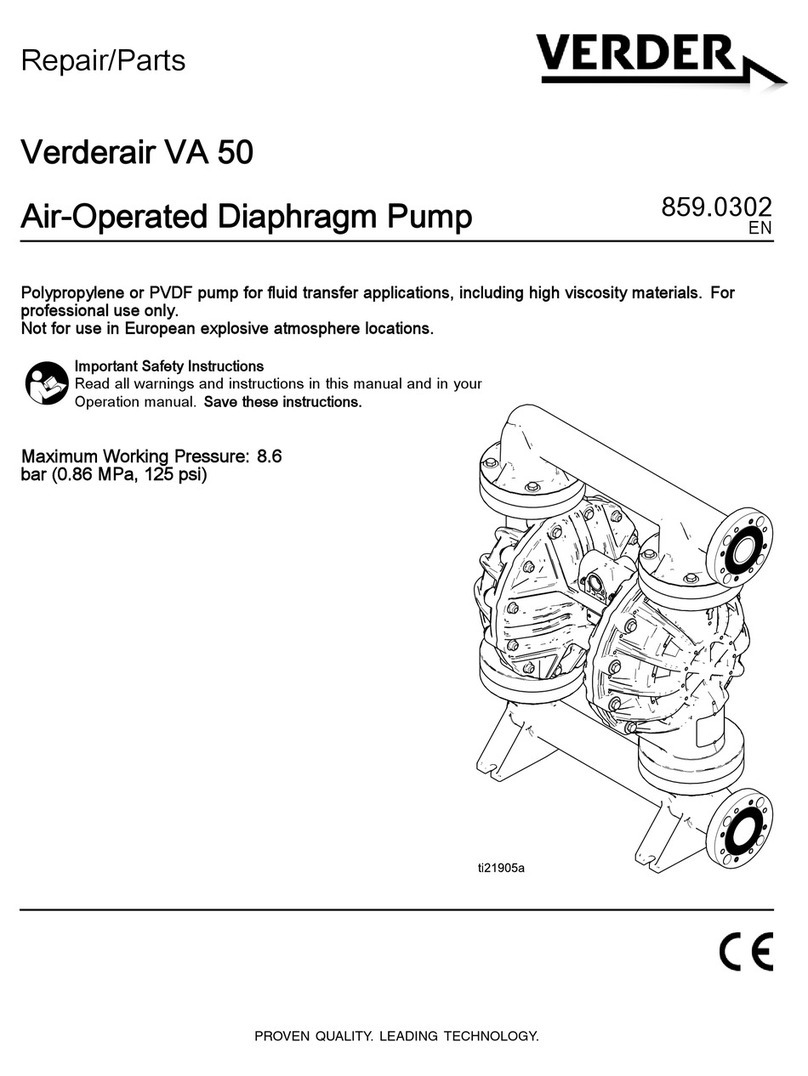

VERDER Verderair VA 50 Use and care manual

VERDER

VERDER JEC JRZP Series User manual

VERDER

VERDER VERDERAIR VA 40 Datasheet

VERDER

VERDER HI-CLEAN VA-2H80HE Instruction Manual

VERDER

VERDER VERDERAIR CONT-EX User manual

VERDER

VERDER VERDERAIR VA-E50 Instruction Manual

VERDER

VERDER VA 50 Operation manual

VERDER

VERDER VERDERAIR VA 25 User manual

VERDER

VERDER VERDERAIR HC-PURE FD Series User manual

VERDER

VERDER AIR VA 8 810.6012 Operation manual

VERDER

VERDER JEC JRZW Series User manual

VERDER

VERDER HI-CLEAN VA-2H80 Use and care manual

VERDER

VERDER Verderflex Vantage 5000 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual