en

Installation and operating instructions • Wilo-Rexa FIT-S • Ed.01/2022-03 3

Table of contents

1 General information...................................................................4

1.1 About these instructions ..................................................... 4

1.2 Digital instructions................................................................ 4

1.3 Copyright ............................................................................... 4

1.4 Subject to change................................................................. 4

1.5 Exclusion from warranty and liability.................................4

2 Safety...........................................................................................4

2.1 Identification of safety instructions................................... 4

2.2 Personnel qualifications....................................................... 5

2.3 Personal protective equipment........................................... 5

2.4 Electrical work .......................................................................5

2.5 Monitoring devices ............................................................... 6

2.6 Fluids hazardous to health................................................... 6

2.7 Transport................................................................................ 6

2.8 Use of lifting equipment......................................................6

2.9 Installing/dismantling........................................................... 7

2.10 During operation ................................................................... 7

2.11 Clean and disinfect ............................................................... 7

2.12 Maintenance tasks................................................................ 7

2.13 Operating fluid ...................................................................... 7

2.14 Operator responsibilities...................................................... 8

3 Transportation and storage.......................................................8

3.1 Delivery................................................................................... 8

3.2 Transport................................................................................ 8

3.3 Storage ................................................................................... 8

4 Application/use...........................................................................9

4.1 Intended use.......................................................................... 9

4.2 Improper use.......................................................................... 9

5 Product description....................................................................9

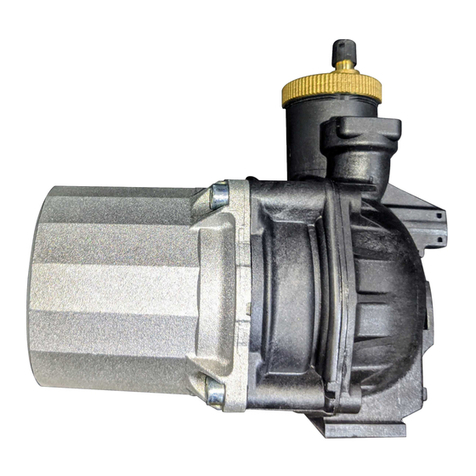

5.1 Description............................................................................. 9

5.2 Materials................................................................................. 9

5.3 Technical data .....................................................................10

5.4 Type key...............................................................................10

5.5 Scope of delivery.................................................................10

5.6 Accessories ..........................................................................10

6 Installation and electrical connection....................................10

6.1 Personnel qualifications.....................................................10

6.2 Installation types.................................................................10

6.3 Operator responsibilities....................................................10

6.4 Installation ...........................................................................11

6.5 Electrical connection..........................................................13

7 Commissioning .........................................................................14

7.1 Personnel qualifications.....................................................14

7.2 Operator responsibilities....................................................14

7.3 Direction of rotation check for three-phase AC motor

...............................................................................................14

7.4 Before switching on............................................................15

7.5 Switching on and off ..........................................................15

7.6 During operation .................................................................15

8 Shut-down/dismantling...........................................................16

8.1 Personnel qualifications.....................................................16

8.2 Operator responsibilities....................................................16

8.3 Shut-down............................................................................16

8.4 Removal.................................................................................16

9 Maintenance and repair............................................................17

9.1 Personnel qualifications......................................................17

9.2 Operator responsibilities.....................................................17

9.3 Operating fluid......................................................................17

9.4 Maintenance intervals .........................................................17

9.5 Maintenance measures .......................................................18

9.6 Repairs ...................................................................................19

10 Faults, causes and remedies ....................................................20

11 Spare parts.................................................................................22

12 Disposal......................................................................................22

12.1 Oils and lubricants................................................................22

12.2 Protective clothing ..............................................................22

12.3 Information on the collection of used electrical and elec-

tronic products .....................................................................22

13 Appendix....................................................................................22

13.1 Tightening torques ..............................................................22