Edition: 02.02.2021

APPROVED USES:

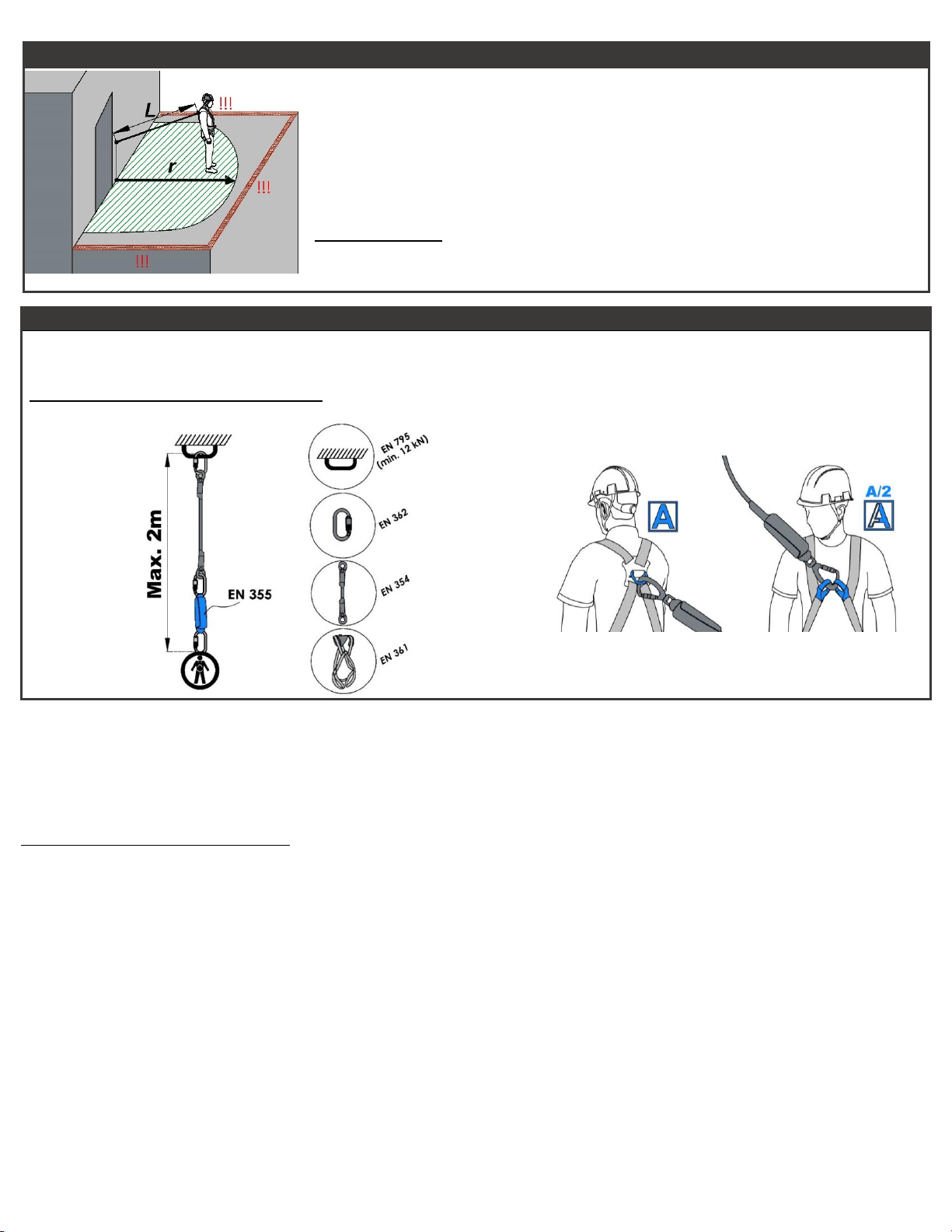

LANYARD + ENERGY ABSORBER (fall arrest systems)

These lanyards can be used also as a shock absorbing lanyards (in fall arrest systems),

only if an energy absorber (acc. to EN 355) is added!

To connect these components, use EN 362 certified carabiners, making sure that

the length of the assembly does NOT exceed 2m!

Before starting the work, make sure there is enough free space below the workplace!

Use only certified full body harnesses (EN 361)! Connect the

absorber end to an attachment point on your harness that is

marked with “A” or „A/2”. These are the only points approved

for fall arrest. The points are usually metal rings or textile loops

and in case of A/2 marking, the two points need to be connected

together! Refer to your full body harness manual for complete

attachment instructions!

Read carefully the instructions of each component of your sys-

tem! In case of uncertainty regarding the equipment seek advice

from the manufacturer or distributor!

WARNING! Before each use a visual inspection and functional test must be performed by the user!

Beware: damages can be inflicted without your knowledge (e.g. negligence of a coworker) and it is important that a visual check is performed before each use!

-The user must monitor their integrity, functionality and correct settings before, during, and after using their PPE!

-Avoid contact of the product with abrasive edges, sharp edges, greases and oils, corrosive chemicals, heat, flames, sparks and incandescent metal splash.

-This products can be used only by trained persons! Beginners may use it only under direct supervision of trained and experienced users!

-It is forbidden to intentionally or accidentally apply mechanical shocks to these products (eg. use for material handling or securing goods during transport etc.)!

The equipment must be withdrawn from use if:

1. The marking/label is missing or is unreadable.

2. DAMAGE has been identified (incisions, cuts, tearing, worn seams, discoloration, hardened or thinned areas, burns, melted areas, rust, plastic defor-

mations) if any other abnormalities of the parts or structure have been found or if the product had suffered any changes compared to its original condition!

3. Contact with paints or unknown chemicals had occurred (irreversible contaminations).

4. The equipment was involved in a fall arrest or had been subjected to heavy loading.

5. The integrity of the equipment is questionable and the inspection log is incomplete or missing.

6. The equipment was in service longer than 10 years.

WARNING! The equipment must be immediately withdrawn from use if it was involved in a fall incident or was subjected to heavy loading! If there is any doubt regarding

the condition of the equipment DO NOT USE it! Instead, send it to the manufacturer or to an authorized representative of the manufacturer for a professional evaluation!

The SERVICE LIFE * of PPE against falls, made of textile materials is 6-8 years under normal conditions, but a maximum of 10 years * from the date of first use. The date of the

first use must be noted in the logbook, otherwise the date of manufacture is considered as the date of the first use. The storage of new, unused products under optimal conditions

(darkness, dryness, original packaging, constant temperature, without chemical vapors, etc.) should not exceed 2 years. * PPE that belongs to a single user, has not been used

excessively and not often, has been subjected to regular checks by experts, has been found to be "safe" and recorded in the test book, has a complete product history, has not

been involved in a fall, is carefully treated and cared for, have been stored in accordance with regulations, have not come into contact with oils, fats or aggressive chemicals,

(attention - incomplete list) can remain in use for up to 10 years. Intensive use, heavy and demanding working conditions, incorrect application, incorrect maintenance and care can

greatly reduce the service life of the equipment. Certain events, such as falls, high exposure to heat, exposure to corrosive chemicals, can limit the use of your equipment to a

single time. A generally valid, binding statement about the duration of use of textile PPE cannot be made, as this depends on a large number of factors such as UV light exposure,

working conditions, contact with various substances, etc. The service life of the equipment ends when one of the cases mentioned in the previous chapter occurs or when the

inspector / certified expert decides this on the basis of other facts. The theoretical total service life of textile PPE against falls (Storage time + Service life) is limited to a maximum

of 12 years from the date of manufacture.

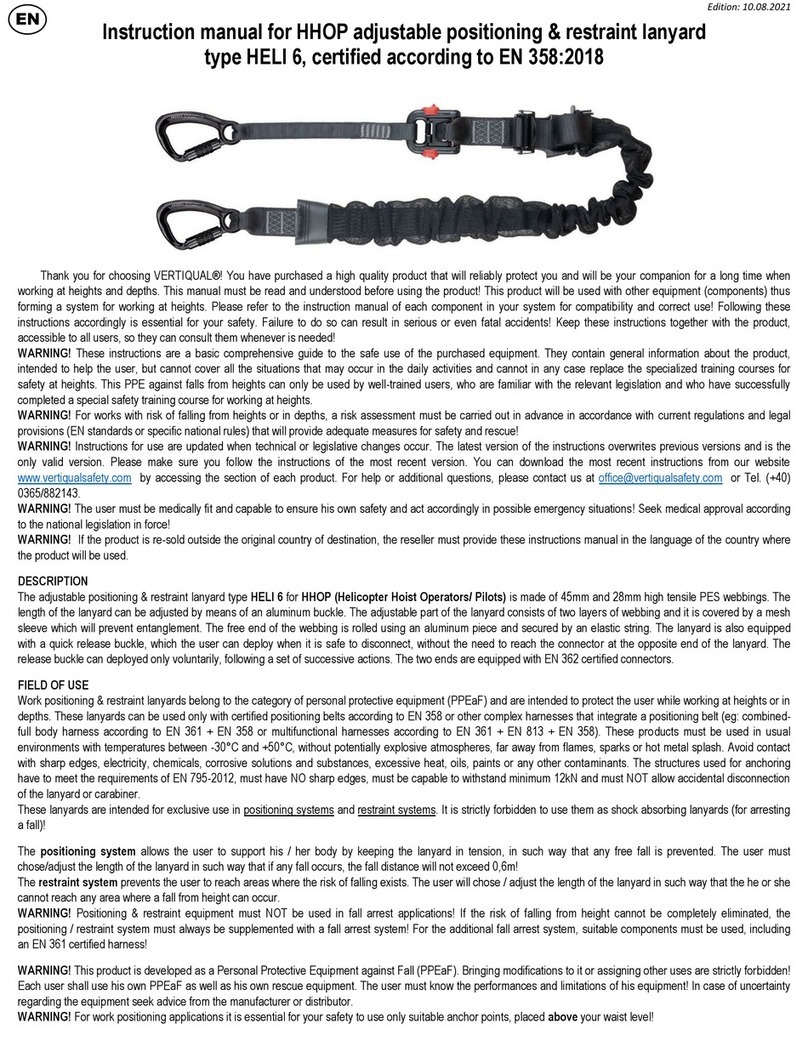

LANYARD ONLY (restraint systems)

The restraint system prevents the user to reach areas where the risk of falling exists.

Connect one end of the lanyard to a suitable anchor point and the other end to the attachment point of a certified

harness (EN 358 / EN 361 / EN 813). Use only EN 362 certified connectors to attach the lanyard and always

take into account the length these connectors add to your lanyard!

L= maximum length of the lanyard (including connectors used)

r = the distance from the anchor point to the closest area with risk of falling

Before starting the work, make sure that the maximum length of the lanyard (including connectors used) is short-

er than de distance to the closest area with risk of falling L< r