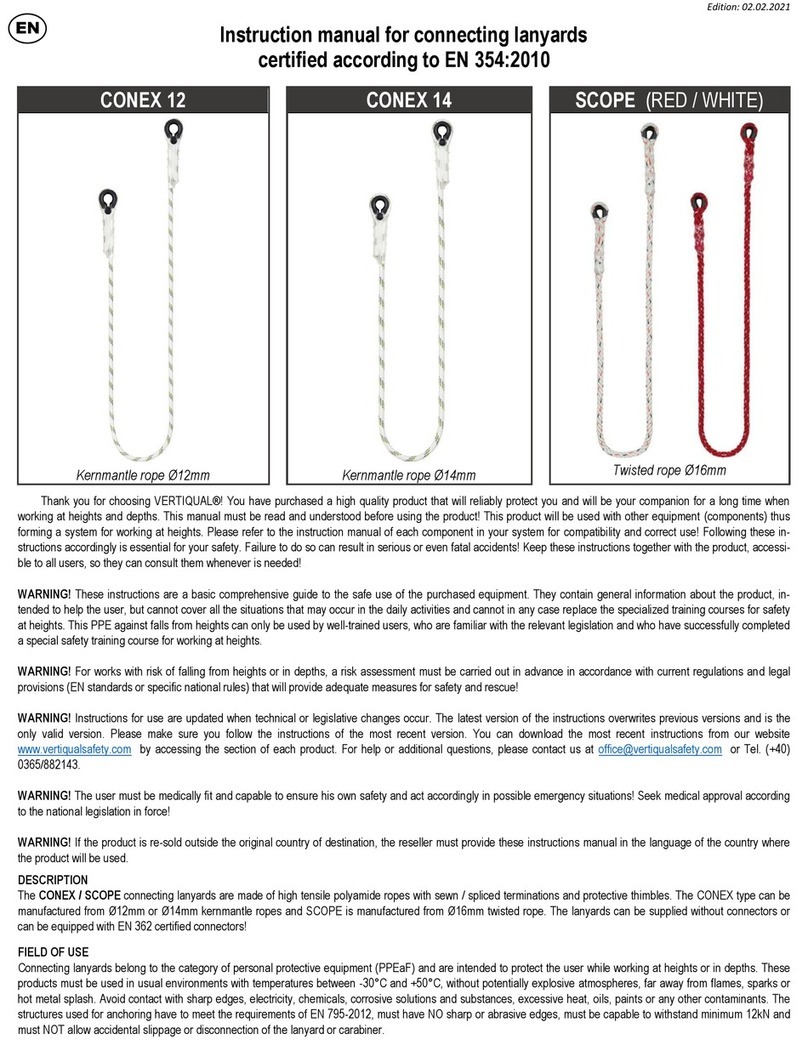

USE WITH EN 355 ENERGY ABSORBER (FALL ARREST)

The length of the final assembly (including con-

nectors) must NOT exceed 2 m! Use only certified

components and read carefully the instructions of each

component you intend to use, in order to validate their

compatibility and learn about their limitations etc.! Make

sure that there is enough free space below your work

surface!

Check your energy absorber before using it!

Never use an absorber that has been damaged or it

had deployed (was involved in a fall arrest)!

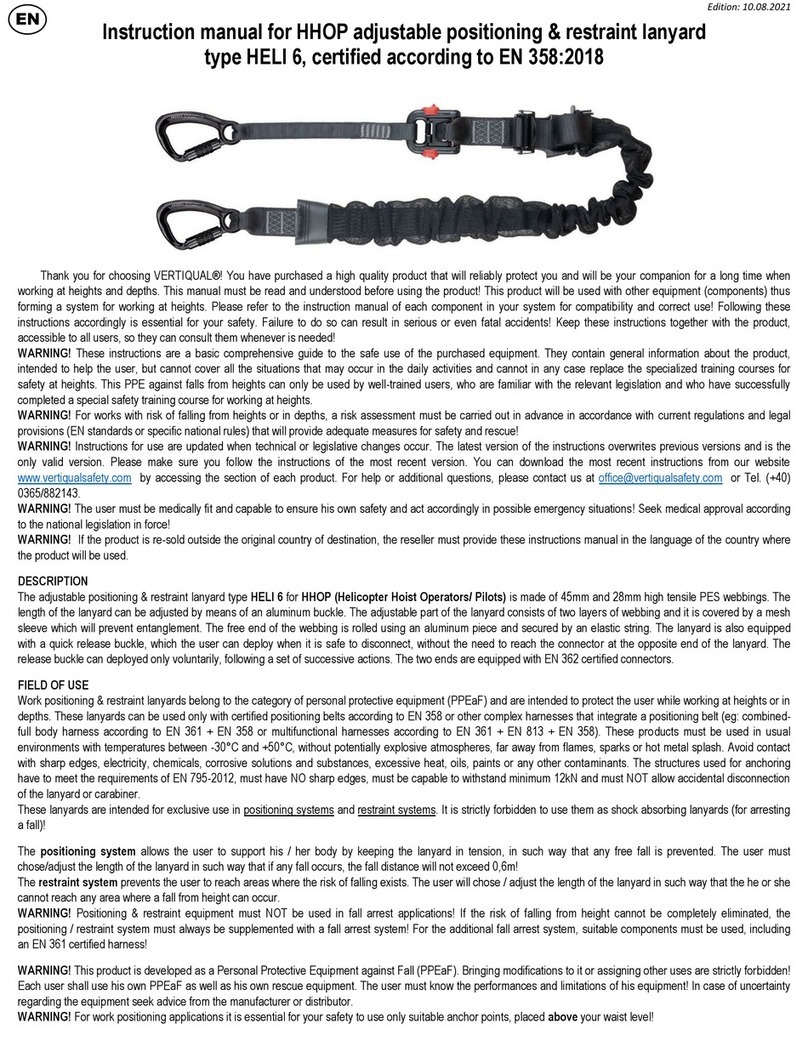

Use as EN 795 / B anchor device

To create an anchor point the anchor lanyard will be attached to a suitable structure. The structures used for anchoring have to meet the requirements of EN 795:2012,

must have NO sharp edges and must be capable to withstand minimum 12 for full metallic anchors or 18 kN for all the others.

The next component of the fall arrest system which will attach to the anchor sling can be:

-Shock absorbing lanyard (EN 354:2010 and EN 355:2002)

-Guided type fall arrester including a flexible anchor line (EN353-2:2002)

-Retractable type fall arresters (EN 360:2002)

-Semi-static and Dynamic ropes of various systems for working at heights

WARNING! If the anchor device is used as a component of a fall arrest system, it is very important that the system includes an energy absorber which will dissipate the

energy of the fall, keeping the arising forces below 6 kN.

WARNING! Do not use the product for lifting or handling materials! Personal Protective Equipment against Falls should never be used as lifting equipment!

WARNING! In use, the load applied to the anchor lanyard (max. 22 kN allowed) will be transmitted to the anchor structure. It is thus necessary to make sure that the struc-

ture has a proven load bearing capacity capable to withstand the load applied to the lanyard for all directions of loading.

WARNING! Before each use a visual inspection and functional test must be performed by the user!

Beware: damages can be inflicted without your knowledge (e.g. negligence of a coworker) and it is important that a visual check is performed before each use!

The equipment must be withdrawn from use if:

1. The marking/label is missing or is unreadable.

2. DAMAGE has been identified (incisions, cuts, tearing, worn seams, discoloration, hardened or thinned areas, burns, melted areas, rust, plastic deformations)

if any other abnormalities of the parts or structure have been found or if the product had suffered any changes compared to its original condition!

3. Contact with paints or unknown chemicals had occurred (irreversible contaminations).

4. The equipment was involved in a fall arrest or had been subjected to heavy loading.

5. The integrity of the equipment is questionable and the inspection log is incomplete or missing.

6. The equipment was in service longer than 10 years.

WARNING! The equipment must be immediately withdrawn from use if it was involved in an incident or was subjected to heavy loading! If there is any doubt regarding the

condition of the equipment DO NOT USE it! Instead, send it to the manufacturer or to an authorized representative of the manufacturer for a professional evaluation!

RESCUE! A rescue plan must be made before starting the work at heights or depths! It is mandatory to set up and know the specific rescue plan for every situation and to

have designated personnel and appropriate means of intervention!

The SERVICE LIFE * of PPE against falls, made of textile materials is 6-8 years under normal conditions, but a maximum of 10 years * from the date of first use. The date of the first

use must be noted in the logbook, otherwise the date of manufacture is considered as the date of the first use. The storage of new, unused products under optimal conditions (dark-

ness, dryness, original packaging, constant temperature, without chemical vapors, etc.) should not exceed 2 years. * PPE that belongs to a single user, has not been used excessive-

ly and not often, has been subjected to regular checks by experts, has been found to be "safe" and recorded in the test book, has a complete product history, has not been involved in

a fall, is carefully treated and cared for, have been stored in accordance with regulations, have not come into contact with oils, fats or aggressive chemicals, (attention - incomplete

list) can remain in use for up to 10 years. Intensive use, heavy and demanding working conditions, incorrect application, incorrect maintenance and care can greatly reduce the ser-

vice life of the equipment. Certain events, such as falls, high exposure to heat, exposure to corrosive chemicals, can limit the use of your equipment to a single time. A generally valid,

binding statement about the duration of use of textile PPE cannot be made, as this depends on a large number of factors such as UV light exposure, working conditions, contact with

various substances, etc. The service life of the equipment ends when one of the cases mentioned in the previous chapter occurs or when the inspector / certified expert decides this

on the basis of other facts. The theoretical total service life of textile PPE against falls (Storage time + Service life) is limited to a maximum of 12 years from the date of manufacture.

STORAGE, MAINTENANCE, TRANSPORT: the equipment should be stored in a dry, cool and well-ventilated room, if possible, in its original packaging. While in storage,

this PPEaF must be protected from UV radiation, solar radiation, heat, sparks, incandescent metal splash, electricity, chemicals, sharp objects, heat sources, dust, cement,

oils and greases or any kind of contaminants. If necessary, the textile parts can be cleaned using warm water (30°C) then rinsed. Drying the wet equipment will be made by

hanging it in well-ventilated room away from any heat source. When fully dried, the equipment can be stored accordingly in its packaging (bag or box). The use of disinfect-

ants is forbidden, as long term effects of various types of disinfectants and concentrations are not known! Transport of the equipment must be made in its protective bag or

box, away from any factor that could contaminate or inflict damage.

MARKING: VERTIQUAL® anchor lanyards are fitted with a label which contains the following elements and essential information: manufacturer (Vertiqual Engineering

S.R.L), name of the model and version (e.g. HELI 11), L = Maximum length of the lanyard (including connectors), L1 = length of the long arm (O ring to end connector), L2 =

length of the short arm (O ring to end connector), manufacturing date (mm/yyyy), standards/norms the product complies to (EN 354:2010, EN 795:2012 / B, CEN/TS