Edition: 02.02.2021

The SERVICE LIFE * of PPE against falls, made of textile materials is 6-8 years under normal conditions, but a maximum of 10 years * from the date of first use. The date

of the first use must be noted in the logbook, otherwise the date of manufacture is considered as the date of the first use. The storage of new, unused products under

optimal conditions (darkness, dryness, original packaging, constant temperature, without chemical vapors, etc.) should not exceed 2 years. * PPE that belongs to a single

user, has not been used excessively and not often, has been subjected to regular checks by experts, has been found to be "safe" and recorded in the test book, has a

complete product history, has not been involved in a fall, is carefully treated and cared for, have been stored in accordance with regulations, have not come into contact

with oils, fats or aggressive chemicals, (attention - incomplete list) can remain in use for up to 10 years. Intensive use, heavy and demanding working conditions, incorrect

application, incorrect maintenance and care can greatly reduce the service life of the equipment. Certain events, such as falls, high exposure to heat, exposure to corrosive

chemicals, can limit the use of your equipment to a single time. A generally valid, binding statement about the duration of use of textile PPE cannot be made, as this

depends on a large number of factors such as UV light exposure, working conditions, contact with various substances, etc. The service life of the equipment ends when

one of the cases mentioned in the previous chapter occurs or when the inspector / certified expert decides this on the basis of other facts. The theoretical total service life

of textile PPE against falls (Storage time + Service life) is limited to a maximum of 12 years from the date of manufacture.

STORAGE, MAINTENANCE, TRANSPORT

The equipment should be stored in a dry, cool and well-ventilated room, if possible, in its original packaging. While in storage, this PPEaF must be protected from UV

radiation, solar radiation, heat, sparks, incandescent metal splash, electricity, chemicals, sharp objects, heat sources, dust, cement, oils and greases or any kind of

contaminants. Buckles and metal parts can be cleand using a soft cloth or using compressed air. If necessary, the textile parts can be claned using warm water (30°C)

then rinsed. Drying the wet equipment will be made by hanging it in well-ventilated room away from any heat source. When fully dried, the equippment can be storred

accordingly in its packaging (bag or box). The use of disinfectants is forbidden, as long term effects of various types of disinfectants and concentrations are not known!

Transport of the equipment must be made in its protective bag or box, away from any factor that could contaminate or inflict damage.

MARKING

All VERTIQUAL® PPEaF are fitted with a label which contains the following elements and essential infromation: name of the manufacturer, name of the model and version

(if applicable),size, manufacturing date (month and year), standards/norms the product complies to, European CE marking with identification number of the notified body

that issued the certificate, international symbol/icon for reading the instructions before use and the product’s serial number. The label must be always present and readable!

PERIODIC INSPECTIONS AND CHECKS

The user must perform a visual and functional inspection of his equipment before and after each use! During use, it is important to monitor your equipment in order to

identify possible damages inflicted in use, without being aware of it. The equipment must be inspected at least once every 12 months or more often if required, depending

on the working conditions and compulsory after every incident it has been involved in. Inspections can be carried out only by the manufacturer or by an authorised inspections

center. If the periodic inspections were not performed at least once every 12 months, were carried out by unqualified persons, or without strictly respecting the

manufacturers instructions, the warranty is lost and the manufacturer declines any responsability related to the equipment!

Inspection Log! Every PPEaF is delivered with an Inspection Log. This document must be kept safely and sent along with the product for every inspection.

The Log (table) contains important data regarding your equipment. The date, signature of the inspector and the results are also recorded. The date of first use must be

written in the Inspection Log by the user!

Repairs or any other modifications can be performed only by the manufacturer! Any repairs,modifications or additions (even minor ones) performed by anyone else are

strictly forbidden, lead to the loss of the manufacturers guarantee and any responsibility related to this product!

WARRANTY AND LIABILITY!

The manufacturer offers a 24 month warranty for this PPEaF from the date of first use.The user has the obligation to write the date of first use in the Inspection Log. If the

date of first use was not filled in, the warranty period will be calculated from the manufacturing date. The warranty is applicable only for material or manufacturing defects!

Damage resulting from normal wear and tear, corrosion, poor maintenance (or no maintenance at all), those resulted from carelessness, accidents, fall arrest, unauthorised

repairs or modifications, wrong use of this PPEaF or any other reasons are NOT covered by the warranty!

The warranty does NOT cover the springs of the carabiners and automatic buckles as these can be damaged due to inadequate storage or improper use.

Warranty claims only apply to the product. All claims by the user or any other party for the direct, indirect or any consequential damages resulting from the use of this

PPEaF are excluded from guarantee and liability assumptions. Any claims in this regard are hereby expressly rejected.

The user must be informed regarding the dangers of work at heights and depths. He should be aware of the risks and he has to be aware that he is the only responsible

for eventual damage, accidents or even death which may result from the use of this equipment. If the user is unable to do so or if he does not have the competence to do

so, he cannot use this PPEaF.

VERTIQUAL Engineering SRL herewith rejects any liability claims for direct, indirect, accidental or consequential damages resulting from the use of this PPEaF (Personal

Protective Equipment against Fall).

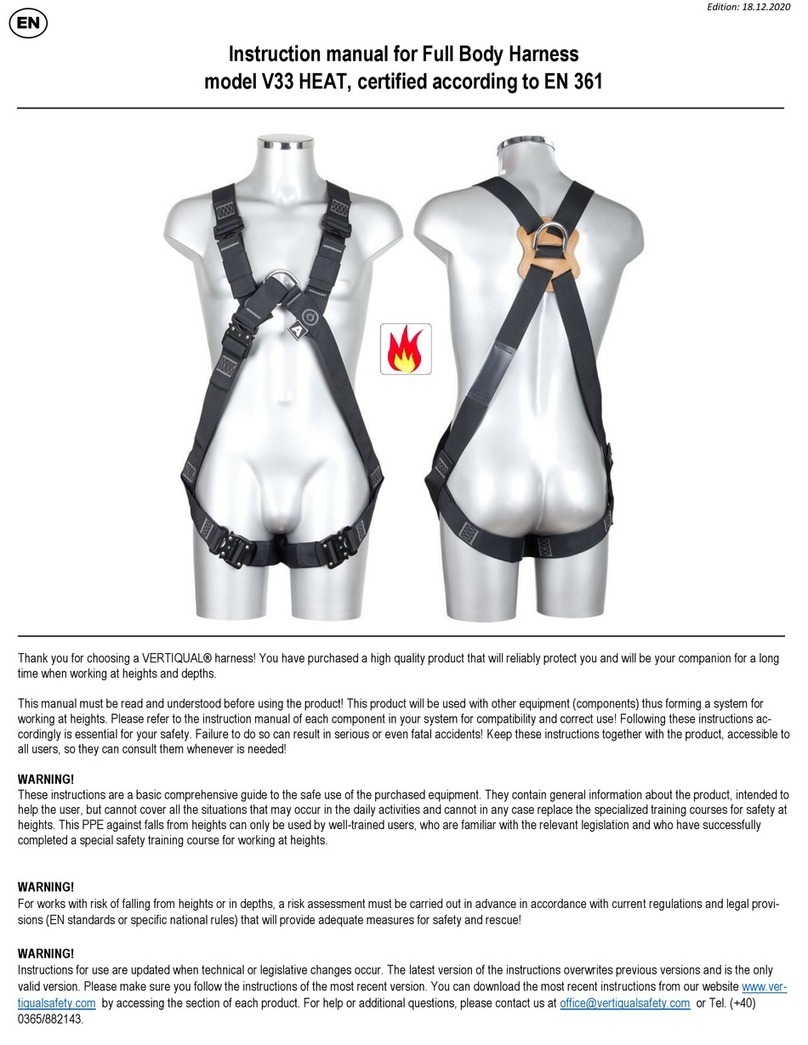

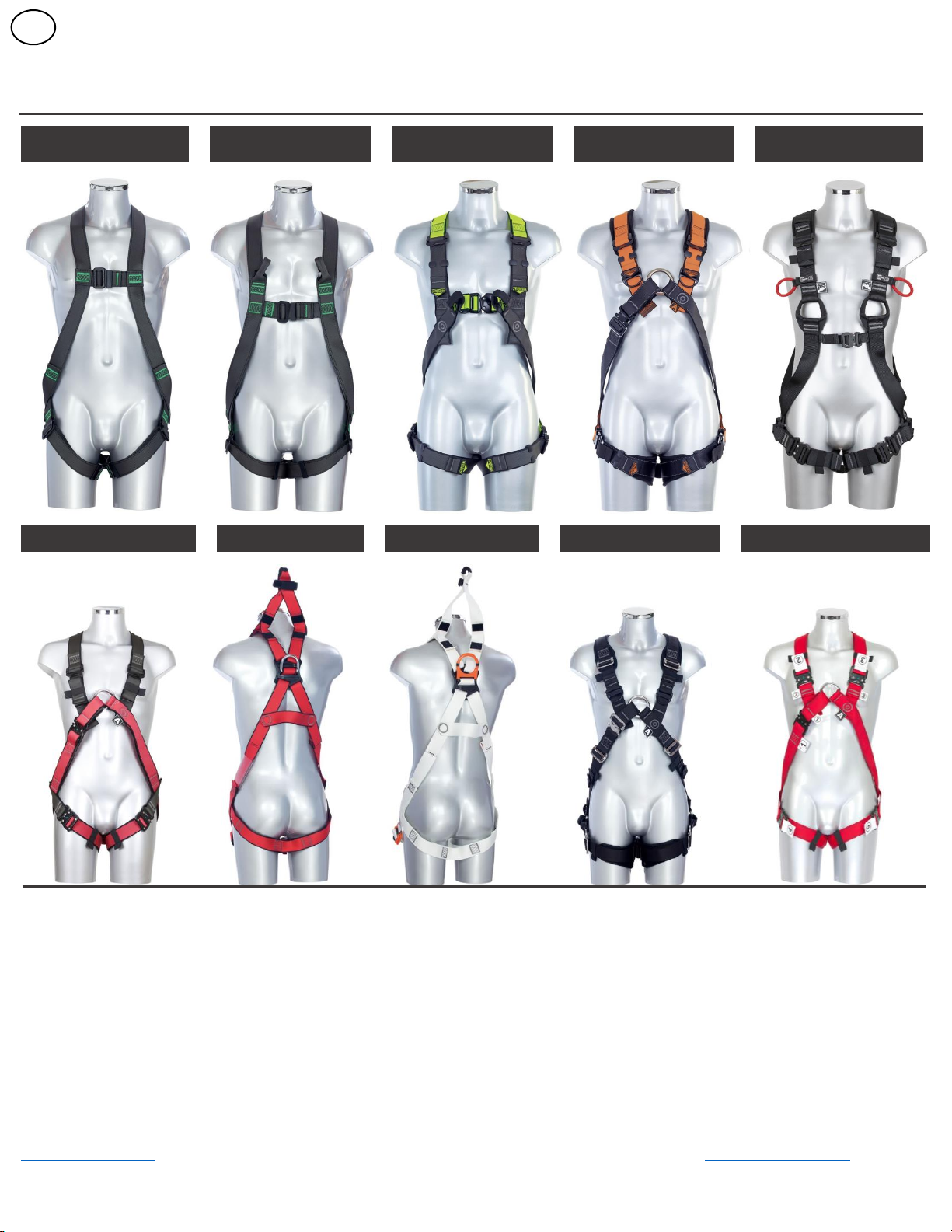

This products comply with the European PPE Regulation (425/2016) and the harmonized standard EN 361:2002. The EU / EC type examination was carried out by NB

1019 (VVUÚ, a.s. Adress: Pikartská 1337/7, 716 07 Ostrava-Radvanice, Czech Republic) for model V20 and NB 2756 (INCDPM - The National Research and Development

Institute for Occupational Safety-Bucharest)for models C2, C3, V3, V33, V34. The production control for all modells is carried out by NB 2756 (INCDPM - The National

Research and Development Institute for Occupational Safety-Bucharest).

The EU / EC Declaration of Conformity can be downloaded from our website www.vertiqualsafety.com by accessing the product’s dedicated section.

Manufacturer: Vertiqual Engineering S.R.L.

RO-547367 Corunca DN1-E60 Nr. 397G

www.vertiqualsafety.com