Last update: 2021/08/26 14:26 d2:quick_start_opls https://www.vescent.com/manuals/doku.php?id=d2:quick_start_opls

https://www.vescent.com/manuals/ Printed on 2021/09/01 05:04

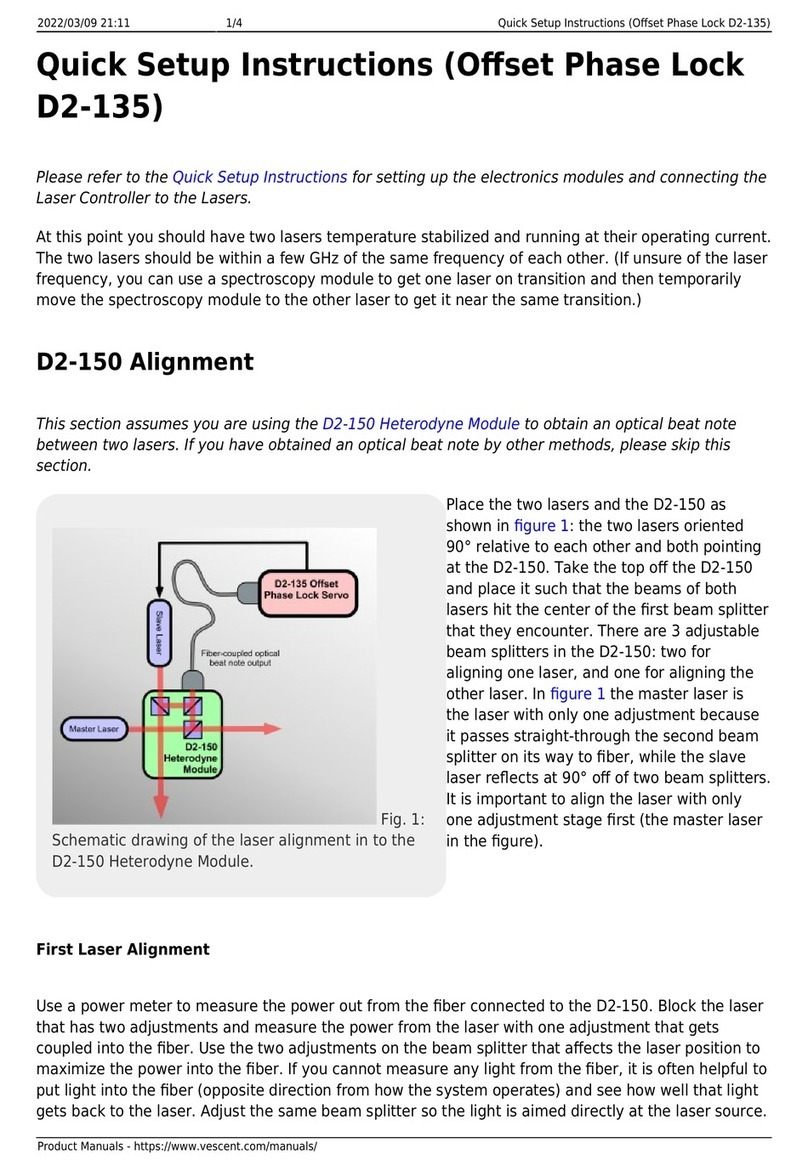

Fig. 2: Schematic drawing of the laser alignment

into the new D2-250 Heterodyne Module.

Heterodyne Module. Take the top off the

D2-250 (-150) and place it such that the

beams of both lasers hit the center of the

first beam splitter that they encounter. There

are 3 adjustable beam splitters in the

D2-150: two for aligning one laser, and one

for aligning the other laser. In figure 1 the

master laser is the laser with only one

adjustment because it passes straight-

through the second beam splitter on its way

to fiber, while the slave laser reflects at 90°

off of two beam splitters. It is important to

align the laser with only one adjustment

stage first (the master laser in the figure).

First Laser Alignment

Use a power meter to measure the power out from the fiber connected to the D2-150. Block the laser

that has two adjustments and measure the power from the laser with one adjustment that gets

coupled into the fiber. Use the two adjustments on the beam splitter that affects the laser position to

maximize the power into the fiber. If you cannot measure any light from the fiber, it is often helpful to

put light into the fiber (opposite direction from how the system operates) and see how well that light

gets back to the laser. Adjust the same beam splitter so the light is aimed directly at the laser source.

This should get the alignment close enough to measure the power in the fiber to use for further

optimization. Aim for 500 μW of power although a few hundred microwatts should be sufficient. The

detector in the D2-160 or D2-135-FC can be damaged by more than 1 mW input power, so be careful

not to couple in too much light.

Second Laser Alignment

Once you have at least a few hundred microwatts of power from the first laser coupled into the fiber,

the next step is to overlap the lasers with two adjustments to the second laser. Unblock the second

laser. The last beam splitter has two outputs: one goes to the fiber, the other to an exit port. This port

is for alignment and portions of both lasers will pass out of this port. Looking at this output close to

the D2-150 and far from the D2-150, one can match the position and angle of the second laser to the

first. When doing the alignment, adjust the beam splitter close to the fiber when looking at the beams

far from D2-150 and use the other beam splitter when looking close to the D2-150. By iterating

adjustments back and forth, you can converge on a nice alignment of the laser. At this point you

should be coupling a few hundred microwatts of power from the second laser into the fiber. If you are

not, try tweaking the beam splitter closest to the slave laser input beam and then repeat the

alignment procedure. Once this is done, you are ready to look for a beat note.