Subject to modifications.© Vestamatic GmbH

Art.-Nr.: 1253 001 GB 2218 A05 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

6/8

G

PRO ·LL-ME-BAT/I-24/0,6 Nm RB IO-AIR

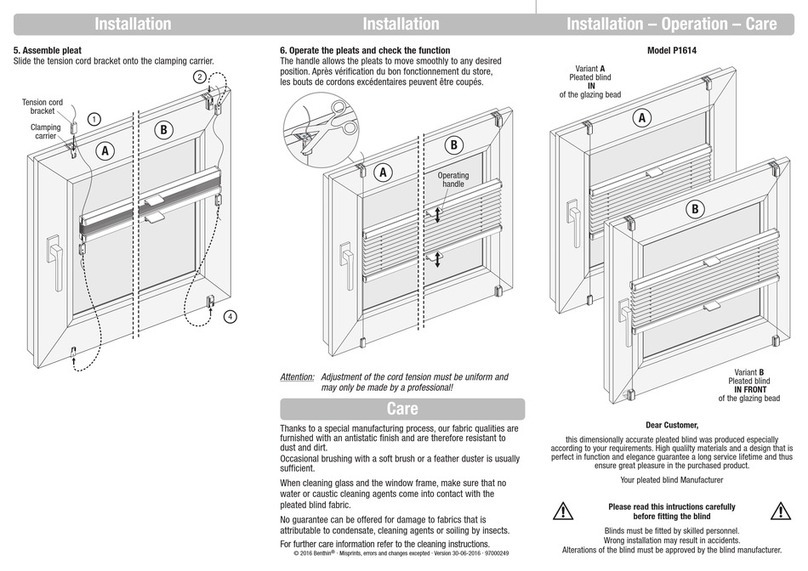

Adjusting already set limit positions of the motor

Change the electronic limit positions

PROG. button

at the back side

IMPORTANT!

The motor starts to move with a short delay time during instal-

lation phase, when no limit positions are set.

ÄStart with lower limit position setting

– Hold down the button to move the motor in the requested lower limit

position.

For precise moving of the motor briefly press the button , press again

and hold.

– Press the following button sequence (within 10 seconds): 5 × short .

– The motor will give a short feedback if the process is finished.

– Hold down the button to move the motor in the requested upper

limit position.

For precise moving of the motor briefly press the button , press again

and hold.

– Press the following button sequence (within 10 seconds): 5 × short

– The motor will give a short feedback if the process is finished.

– The installation procedure is finished and the limit position settings are

saved.

– The blinking of the LEDs on the front side of the remote control disap-

pears after about 10 seconds, then the motor can be driven.

NOTE:

Adjusting only with

radio remote control,

not available with wall-

mounted transmitter.

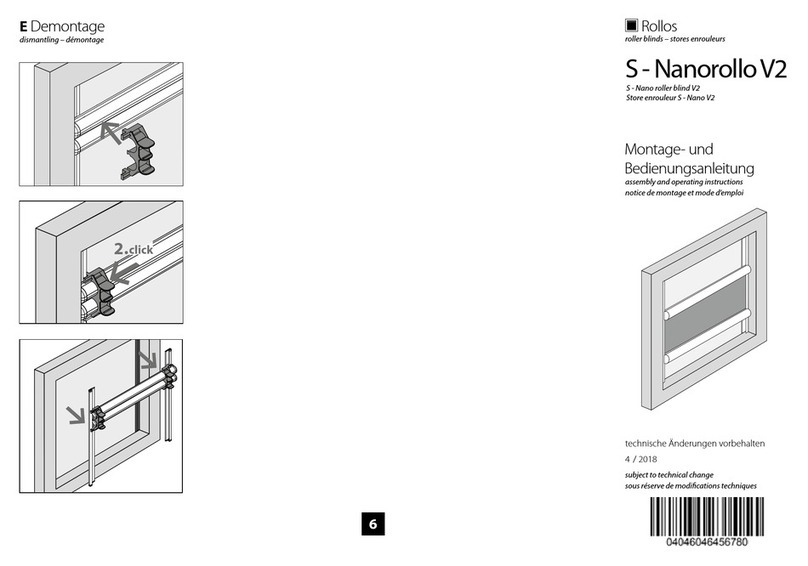

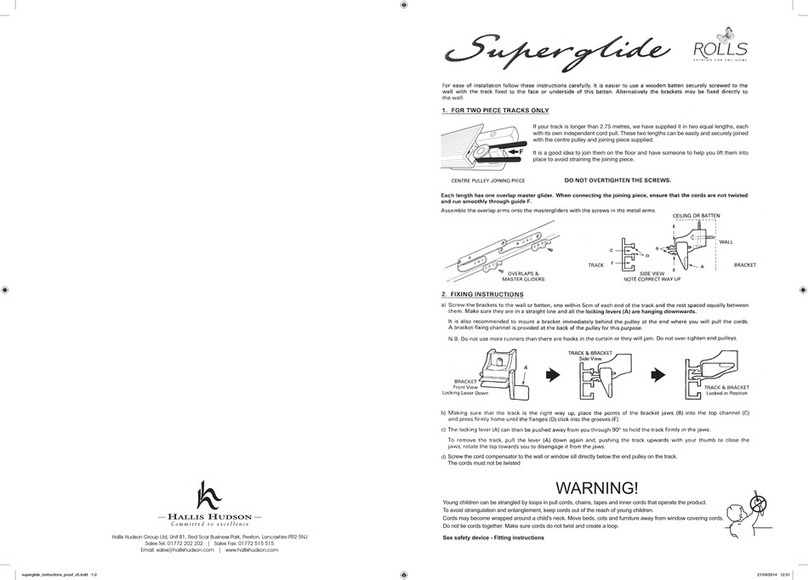

Press the PROG. button twice

(see figure left) on the back side of

the radio remote control until the

following LEDs flash.

i

– The intermediate position can be saved only after

the lower and upper limit positions have been

saved finally.

– Briefly press the UP or DOWN button = self-locking.

Press the opposite button or STOP button to stop

drive.

– When the desired position is reached, press the

following button sequence (within 10 seconds):

5 × shortly the STOP button.

– The motor will give a feedback (short UP/DOWN

movement) to confirm that the installation proce-

dure has ended.

Save intermediate position

NOTE:

Save intermediate position (only with radio remote control, not

available with wall-mounted transmitter).

i– Once the intermediate position is stored, the motor reacts according to

button stroke length.

Briefly press the UP or DOWN button = Intermediate position.

Press the button UP or DOWN twice = run over the intermediate

position.

– The stored intermediate position can be changed/overwritten at any

time.

Deleting the intermediate position:

– Driving the motor in the lower limit position.

– When the limited position is reached, press the following button sequence

(within 10 seconds): 5 × briefly the STOP button.

– The motor will give a short feedback if the process is finished.

By means of the programmed radio remote control

– Press the PROG. button (see

figure left) on the back side of

the radio remote control several

times until the following LEDs

flash. Then press the STOP

button.

– The motor briefly performs

ON/UP and OFF/DOWN com-

mands. The blinking of the LEDs

on the front side of the remote

control disappears after about

1 seconds, then the motor can

be driven.

After the motor RESET, the programming mode is automatically active

for 60 seconds. The motor starts to move with a short delay time during

installation phase, when no limit positions are set.

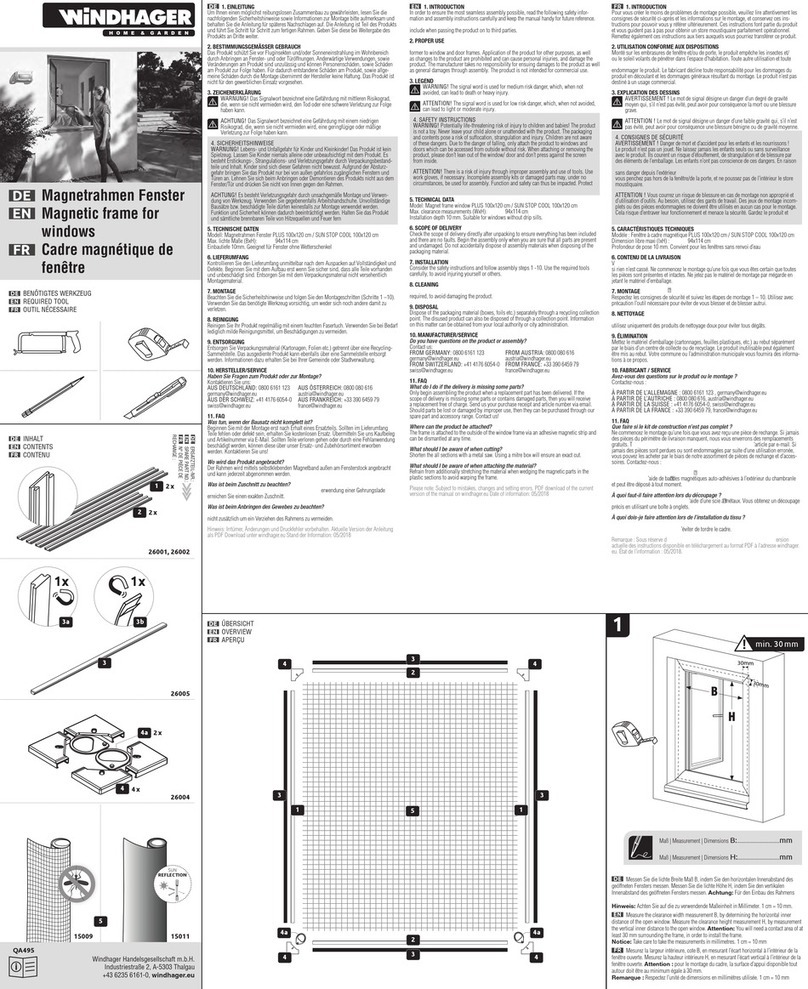

Motor – RESET

PROG. button

at the back side

By means of the PROG. button at the motorhead

– Press and hold the PROG. button (see figure right) on the motorhead

for about 10 seconds until the green LED is constantly lit.

Now release the PROG. button again.

– The motor acknowledges the RESET by a short flashing of the blue

LED.

NOTE:

If a RESET is carried out using the PROG. button on the motor

head, the programming mode does not activate automatically.

i

Delete the limit position settings of the motor and

all programmed radio transmitter

1 PROG. button

2 Blue LED

3 Green LED