rev. 1/7/2013 FC-29, manual

Hazard Identification--Explanation of SIGNAL WORDS

This manual uses SIGNAL WORDS to indicate the likelihood of personal injuries, as well as the probable

seriousness of those injuries, if the product is misused in the ways described. Other signal words call attention to

uses of the product likely cause property damage.

The signal words used appear below along with the meaning of each word:

Identifies a hazardous situation which, if not avoided, WILL result in DEATH or

SERIOUS INJURY. Use of this signal word is limited to the most extreme

situations.

Identifies a hazardous situation which, if not avoided, COULD result in DEATH or

SERIOUS INJURY.

Indicates a hazardous situation which, if not avoided, COULD result in MINOR or

MODERATE injury.

Identifies practices likely to result in product/property damage, such as operation that

might damage the product.

Each person who assembles, installs, uses, or maintains this product should read the entire manual in advance

and fully understand the directions. If after reading the manual you do not understand an instruction, ask

your supervisor or employer for clarification, because failure to adhere to the directions in this manual

might result in serious personal injury.

SAFETY GUIDELINES

Vestil diligently strives to identify foreseeable hazards associated with the use of its products. However, material

handling is inherently dangerous and no manual can address every conceivable risk. The end-user ultimately is

responsible for exercising sound judgment at all times.

Electrocution might result if any part of the fork caddy or fork tine in the caddy contacts electrified wires.

Reduce the likelihood of electrocution by applying common sense:

DO NOT contact electrified wires with any part of the caddy or the fork in it;

DONOT use the caddy in a location where contact with electrified wires will or is likely to occur.

If this product is used improperly or carelessly, the operator and/or bystanders might sustain serious

personal injuries. ALWAYS use the product properly:

Failure to read and understand the entire manual before assembling, installing, using or servicing the

product constitutes misuse.Read the manual to refresh your understanding of proper use and maintenance

procedures as necessary.

DO NOT exceed the maximum rated load.

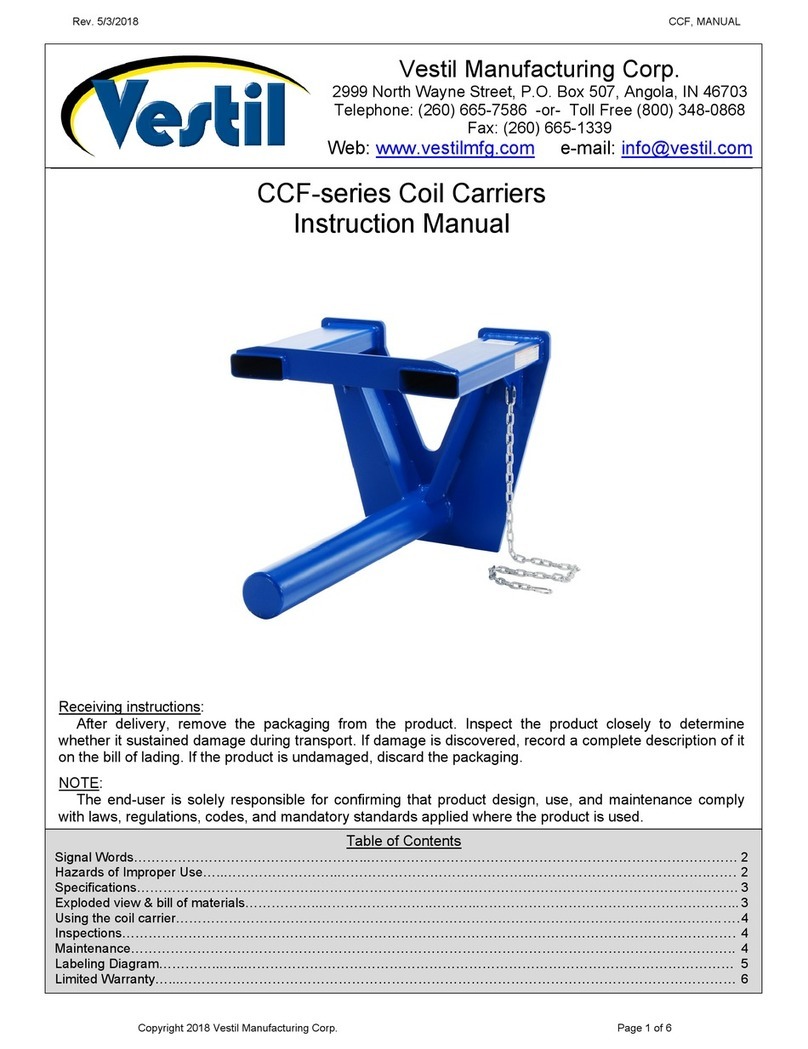

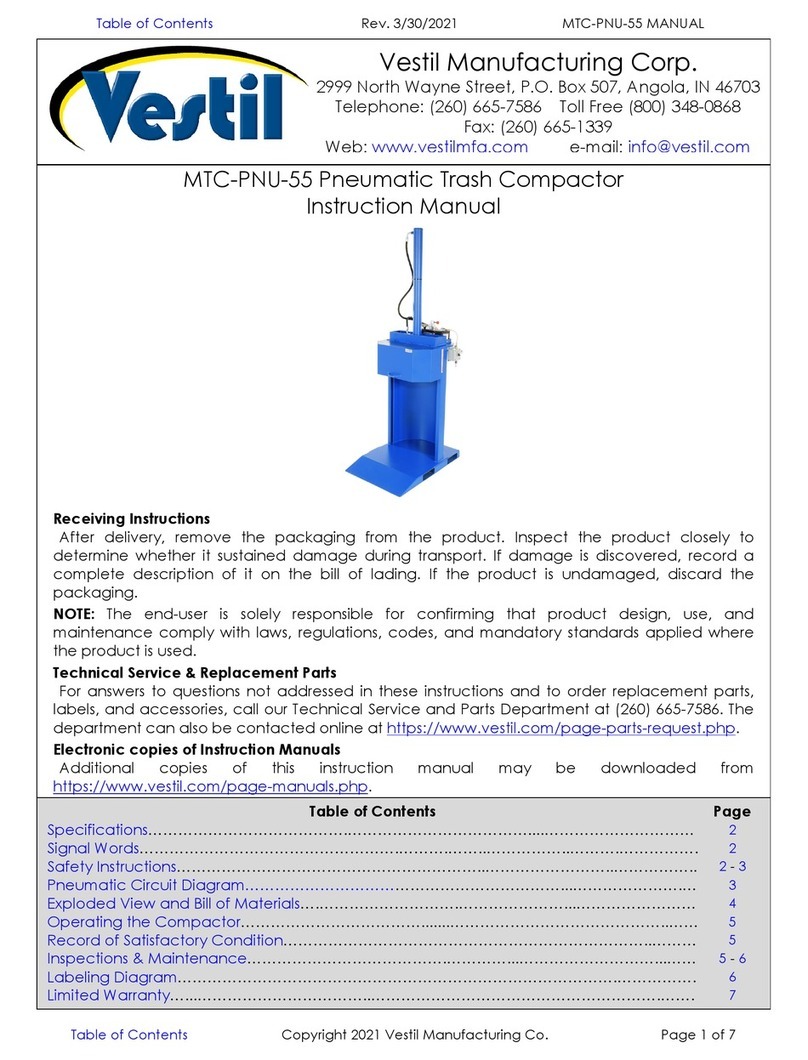

Referring to FIG. 1 on p. 3, inspect the caddy before each use. DO NOT use this device if the inspection reveals

structural damage. Examples of structural damage include: 1) broken, deformed, etc. fork/tine carrier or handle; 2)

cracked welds; 3) enlarged openings for fasteners, particularly the threaded opening for the star knob; 4) corrosion,

severe wear, or other condition that affects the ability of the product to support applied weight. Immediately tag out the

caddy and replace each part that fails to pass an inspection. DO NOT use the product until it is fully restored to normal

condition. ONLY use manufacturer-approved replacement parts.

DO NOT use the product if any unusual noise or movement is observed. If a malfunction occurs, remove the unit from

service and notify your supervisor or maintenance personnel about the issue.

ALWAYS securely engage a fork/tine with the star knob BEFORE using the caddy to transport the tine.

Push the caddy whenever it is loaded with a fork / tine to keep the end of the tine in sight. Avoid contact with the tine.

DO NOT leave a fork in the caddy unattended. ALWAYS unload the caddy before it will be unattended for longer than

a few minutes.

DO NOT remove or obscure any label. All product labels must be readable and undamaged.

DO NOT modify the table in any way UNLESS you first obtain written approval from Vestil. Unauthorized

modifications automatically void the limited warranty (see p. 5) and might make the table unsafe to use.

Proper use, maintenance, and storage are essential for this product to function properly.

oAlways use this product in accordance with the instructions in this manual and consistent with any relevant training.

oStore the caddy someplace where it will remain dry.

Copyright 2013 Vestil Manufacturing Corp. Page 2 of 5