REV I | 8/6/19

6

If any safety decal is damaged or not readable, shut down the equipment and do not resume operation

until the decal is replaced. For current pricing and delivery, contact the manufacturer to reorder safety

decals.

3.3 Material Safety

DANGER: Do not process ammable, explosive, toxic, or otherwise hazardous materials without rst

performing an appropriate Process Hazard Analysis (PHA).

The manufacturer cannot be an expert in the chemical and biological properties of the innite number

of materials that could be handled by this equipment. This equipment is not designed to safely process

hazardous materials unless additional precautions are taken.

Beforeprocessinganymaterialsthatareorcanreacttobecomeammable,explosive,toxic,orotherwise

hazardous, the user/owner must perform a thorough risk assessment and Process Hazard Analysis of the

entire process, including contingency plans for dealing with processing errors and upset conditions.

3.4 Energy Isolation

DANGER: Electrical enclosures contain hazardous voltage that will result in electrical shock or burn. Turn

oandlockoutequipmentbeforeservicing.

DANGER:Equipmentwithintheelectricalenclosureposesashockandarcashhazardthatmaycause

severe injury or death. Wear proper protective equipment before opening or performing diagnostic

measurementsortestingwhileenergized.Onlyqualiedpersonsshouldopenorworkwithintheelectrical

enclosure.

This equipment must have a lockable isolation/relief device for each energy source. If these device(s)

are not purchased with the equipment, the customer must provide and install a lockable isolation/relief

device for each energy source (in accordance with federal, state, and local codes/standards).

3.4.1 Energy Sources

This equipment incorporates separate energy sources. Proper shutdown and lockout/tag-out

must only be performed by qualied personnel, and must include disabling of all energy

sources including but not limited to the following:

NOTE: Your system may not use all energy sources listed below.

• Electrical:Shutoandlockoutallelectricaldisconnects.Verifyelectricalpowerisin

the o state.

• Pneumatic:Disconnect/shutoairsupply,bleedairfromtheequipment,andlockout.

Verify that energy is relieved/restrained appropriately.

3.4.2 Energy Isolation Method

Before adjusting, servicing, repairing, maintaining, or clearing blockages from this equipment,

complete the procedure below.

1. Review and become familiar with all documentation and schematics. Identify energy

sources and stored energy.

2. Wear appropriate PPE.

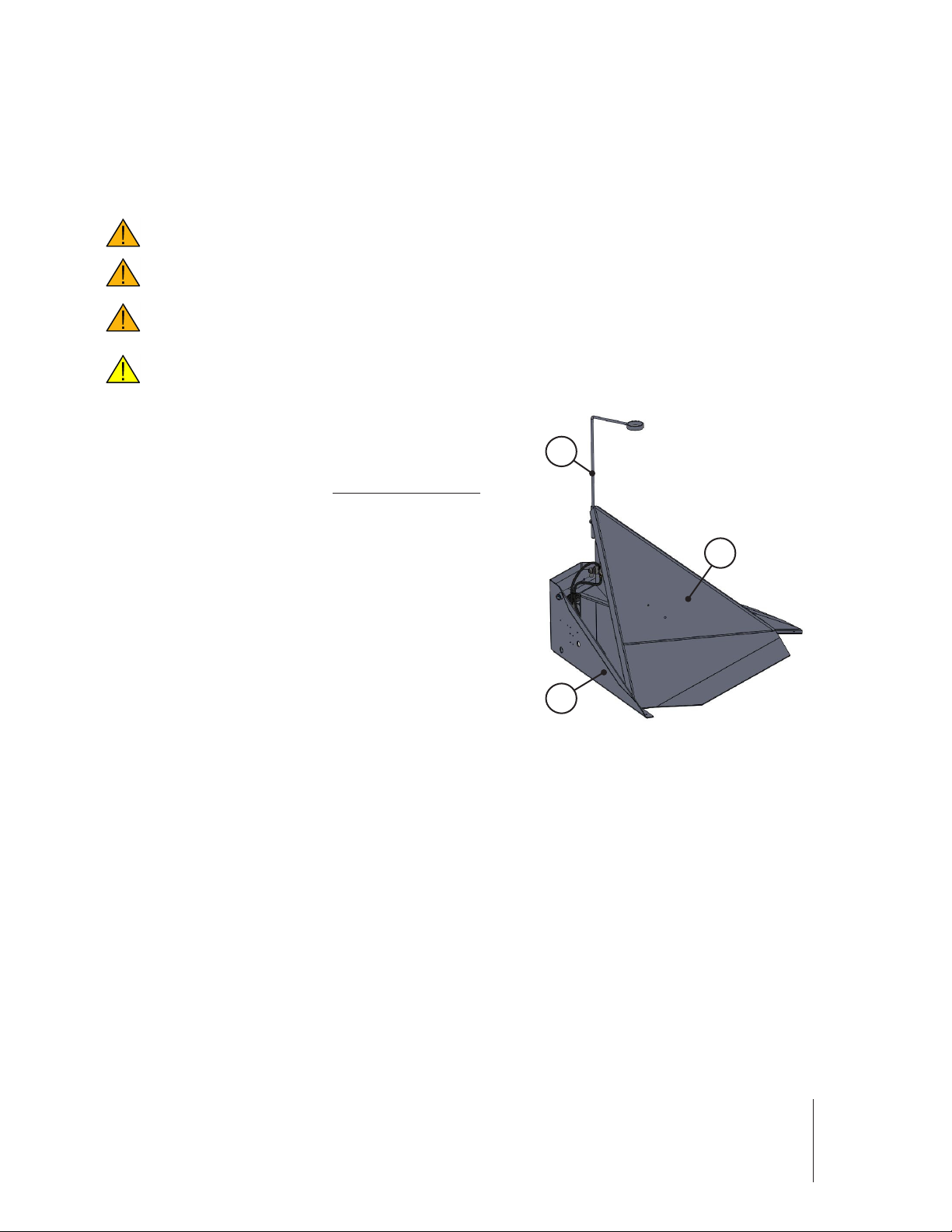

3. Fully lower the FLT bucket.

4. Shuto/disconnectthemainairsupply.Allowairtofullybleedfromequipment.

5. Identify and release stored energy as necessary.