TABLE OF CONTENTS 7/23/2021 DCBB, MANUAL

TABLE OF CONTENTS Copyright 2021 Vestil Manufacturing Co. Page 6 of 6

LIMITED WARRANTY

Vestil Manufacturing Corporation (“Vestil”) warrants this product to be free of defects in material and

workmanship during the warranty period. Our warranty obligation is to provide a replacement for a

defective, original part covered by the warranty after we receive a proper request from the Warrantee

(you) for warranty service.

Who may request service?

Only a warrantee may request service. You are a warrantee if you purchased the product from Vestil or

from an authorized distributor AND Vestil has been fully paid.

Definition of “original part”?

An original part is a part used to make the product as shipped to the Warrantee.

What is a “proper request”?

A request for warranty service is proper if Vestil receives: 1) a photocopy of the Customer Invoice that

displays the shipping date; AND 2) a written request for warranty service including your name and phone

number. Send requests by one of the following methods:

US Mail Fax Email

Vestil Manufacturing Corporation (260) 665-1339 info@vestil.com

2999 North Wayne Street, PO Box 507 Phone Enter “Warranty service request”

Angola, IN 46703 (260) 665-7586 in the subject field.

In the written request, list the parts believed to be defective and include the address where replacements

should be delivered. After Vestil receives your request for warranty service, an authorized representative will

contact you to determine whether your claim is covered by the warranty. Before providing warranty

service, Vestil will require you to send the entire product, or just the defective part (or parts), to its facility in

Angola, IN.

What is covered under the warranty?

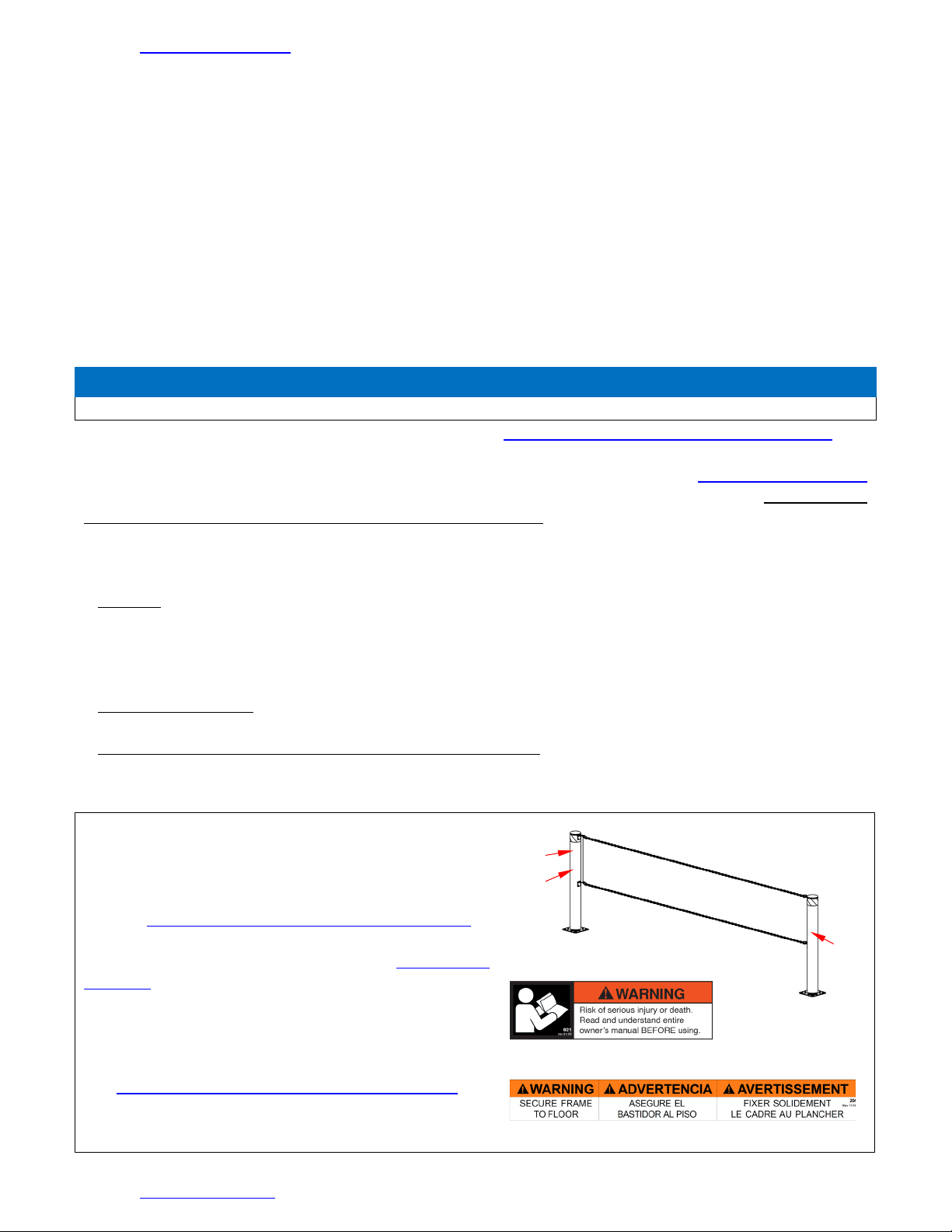

The warranty covers defects in the following original, dynamic parts: motors, hydraulic pumps, motor

controllers, and cylinders. It also covers defects in original parts that wear under normal usage conditions

(“wearing parts”), such as bearings, hoses, wheels, seals, brushes, and batteries.

How long is the warranty period?

The warranty period for original dynamic components is 90 days. For wearing parts, the warranty period is

90 days. Both warranty periods begin on the date Vestil ships the product to the Warrantee. If the product

was purchased from an authorized distributor, the periods begin when the distributor ships the product.

Vestil may, at its sole discretion, extend a warranty period for products shipped from authorized distributors

by up to 30 days to account for shipping time.

If a defective part is covered by the warranty, what will Vestil do to correct the problem?

Vestil will provide an appropriate replacement for any covered part. An authorized representative of

Vestil will contact you to discuss your claim.

What is not covered by the warranty?

The Warrantee (you) is responsible for paying labor costs and freight costs to return the product to Vestil

for warranty service.

Events that automatically void this Limited Warranty.

•Misuse;

•Negligent assembly, installation, operation or repair;

•Installation/use in corrosive environments;

•Inadequate or improper maintenance;

•Damage sustained during shipping;

•Collisions or other accidents that damage the product;

•Unauthorized modifications: Do not modify the product IN ANY WAY without first receiving written authorization

from Vestil.

Do any other warranties apply to the product?

Vestil Manufacturing Corp. makes no other express warranties. All implied warranties are disclaimed to

the extent allowed by law. Any implied warranty not disclaimed is limited in scope to the terms of this

Limited Warranty. Vestil makes no warranty or representation that this product complies with any state or

local design, performance, or safety code or standard. Noncompliance with any such code or standard is

not a defect in material or workmanship.