Instructions for Use

Page 3

c) Fall Clearance: ensure that adequate clearance exists in your fall path to

prevent striking an object. The clearance required is dependent on the

length and type of lanyard and anchorage location.

d) Personal Fall Arrest System: Reliance recommends the use of a per-

sonal fall arrest system with this equipment. the personal fall arrest

system will protect the user if the work positioning system disengages

from the anchorage point, or when detached from the work position-

ing system when moving from point to point. see osha 3926.503 and

3926.3053.

e) Environmental Hazards: use of this equipment in areas where envi-

ronmental hazards are present may require additional precautions to

reduce the possibility of injury to the user or damage to the equipment.

hazards may include, but are not limited to; high heat, sever cold, caus-

tic chemicals, corrosive environments, high voltage power lines, explo-

sive or toxic gases, moving machinery, or sharp edges.

f) Training: this equipment is intended to be used by persons trained in its

correct application and use.

3) Applicable Standards: Refer to national standards, including the ANSI

Z359 family of standards on fall protection, ANSI A30.32, and applicable lo-

cal, state, and federal (OSHA) requirements governing occupational safety, for

more information on work positioning systems.

SYSTEM REQUIREMENTS

1) Compatibility of Components and Subsystems: This equipment is de-

signed for use with Reliance approved components and subsystems. Substi-

tutions or replacements made with non-approved components or subsystems

may be incompatible, and may jeopardize the safety and reliability of the com-

plete system.

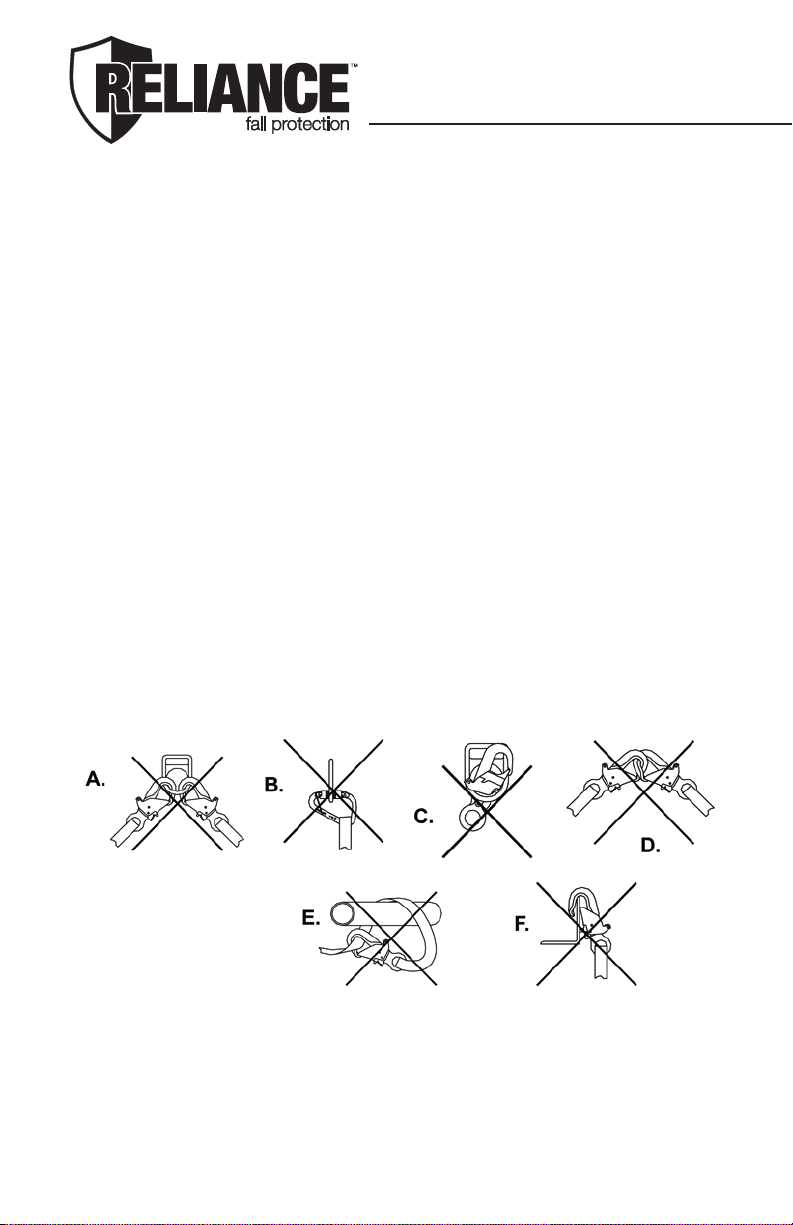

2) Compatibility of Connectors: Connectors are considered to be compatible

with connecting elements when they have been designed to work together in

such a way that their sizes and shapes do not cause their gate mechanisms to

inadvertently open regardless of how they become oriented. Contact Reliance

if you have any questions about compatibility. Connectors (hooks, carabiners,

and D-rings) must be capable of supporting at least 5,000 lbs. (22.2 kN). Con-

nectors must be compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible connectors may

unintentionally disengage. Connectors must be compatible in size, shape, and

strength. Self locking snap hooks and carabiners are required by ANSI Z359.3,

OSHA, and CSA Z259.32.