Rev. 5/19/2015 PEL-88-A-SWA, MANUAL.doc

Copyright 2015 Vestil Manufacturing Co. Page 9 of 11

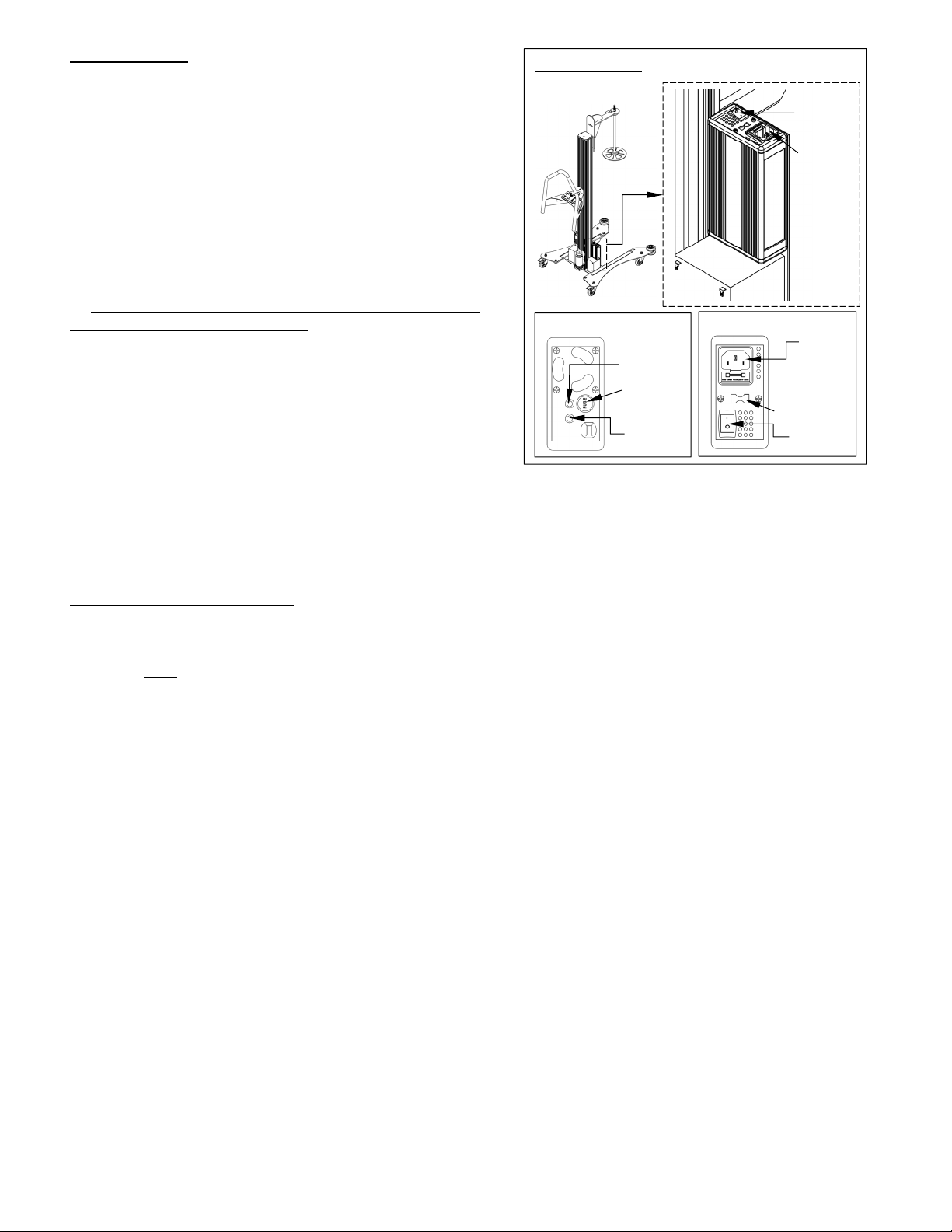

System power:

Power is supplied by two 12V batteries. Both batteries are

completely sealed and are therefore maintenance free.

To recharge the batteries, every wrapping machine includes a

24V charger. The charger operates on 115 VAC and requires a

3-prong (grounded) extension cord. The charger monitors and

reacts to the battery voltage during the recharging process.

When the batteries are fully charged, a green LED on the bottom

of the charger turns on (see diagrams to the right). The battery

charge gauge (see “Touchpad control” on p. 6) displays the

amount of battery charge remaining as a percentage of full

(100%) charge. To determine the true level of charge, wait at

least 1/2 hour after turning off the charger. If the voltage is

12.65V or more, then the batteries are fully charged.

Charge the batteries for at least 4 hours before using the

wrapping machine for the first time.

How frequently the batteries require charging depends on the

load applied to the batteries (i.e. how many times the carriage is

moved and how quickly—faster speed will drain the battery more

rapidly) and the duration and frequency of use. Experience will

dictate when the batteries should be charged.

Whenever recharging is begun, it should continue until the

batteries are fully charged. Do not interrupt the charging cycle.

Fully charging the batteries every time recharging is undertaken

maximizes battery life.

Recommendations regarding battery charging: 1) Recharge the batteries at least once every 2 weeks; 2) Leave

the charger plugged in when the unit is not in use (the battery charger can remain connected to the batteries for long

periods without causing damage to the batteries); 3) Disconnect the batteries when the unit will be unused for 1 month

or longer; 4) ALWAYS keep the wrapping machine dry.

Inspections & Maintenance:

If any of the inspections described below reveal problems, tag the unit “Out of Service”. Restore the machine to

normal operating condition BEFORE using it again.

A. Before each use, inspect the following components. Each component must be in normal operating condition. To

establish normal operating condition, make a thorough record of the appearance, sound, and function of the various

parts of the wrapping machine when you first receive it. Compare later observations to the record to determine

whether the machine is in normal operating condition.

1. Frame: examine the frame, roller brackets, and handle weldment. Look for damaged welds, warps, cracks, or

other deformations.

2. Casters: examine each caster. Confirm that casters are not severely worn, swivel freely, and that the brakes

firmly engage the wheels.

3. Carriage mechanism: cycle the carriage by raising it to the top of the mast and then lowering it completely. The

carriage should move smoothly and at a uniform rate up-and-down the mast. Watch for binding and listen for

unusual sounds.

4. Fasteners: check bolts and nuts. Make sure all fasteners are tightly connected.

5. Roller bearings: look inside the channel of the mast and examine the roller bearings of the carriage (see FIGS.

1 and 3). Clean the interior of the mast to remove debris that might interfere with the rollers.

B. At least once per month:

1. Wiring: inspect the electrical system and look for loose connections and damage.

2. Clean the machine: remove dirt and other matter from all surfaces.

3. Labels: refer to the “Labeling Diagram” on p. 10. Make sure that all labels are in place and readable.

4. Batteries: remove corrosion from the posts if present.

Battery charger:

Power

switch

Outlet for

charging

cord

Bottom face of charger:

Top face of charger:

Charging

LED

Power

LED

6.3A/250V

fuse

Power

switch

Flanged

inlet for

cord

115-230VAC

selectable