VCB and VCB N C.Tec Bags 12 bar (174 psi)

Page 3/22

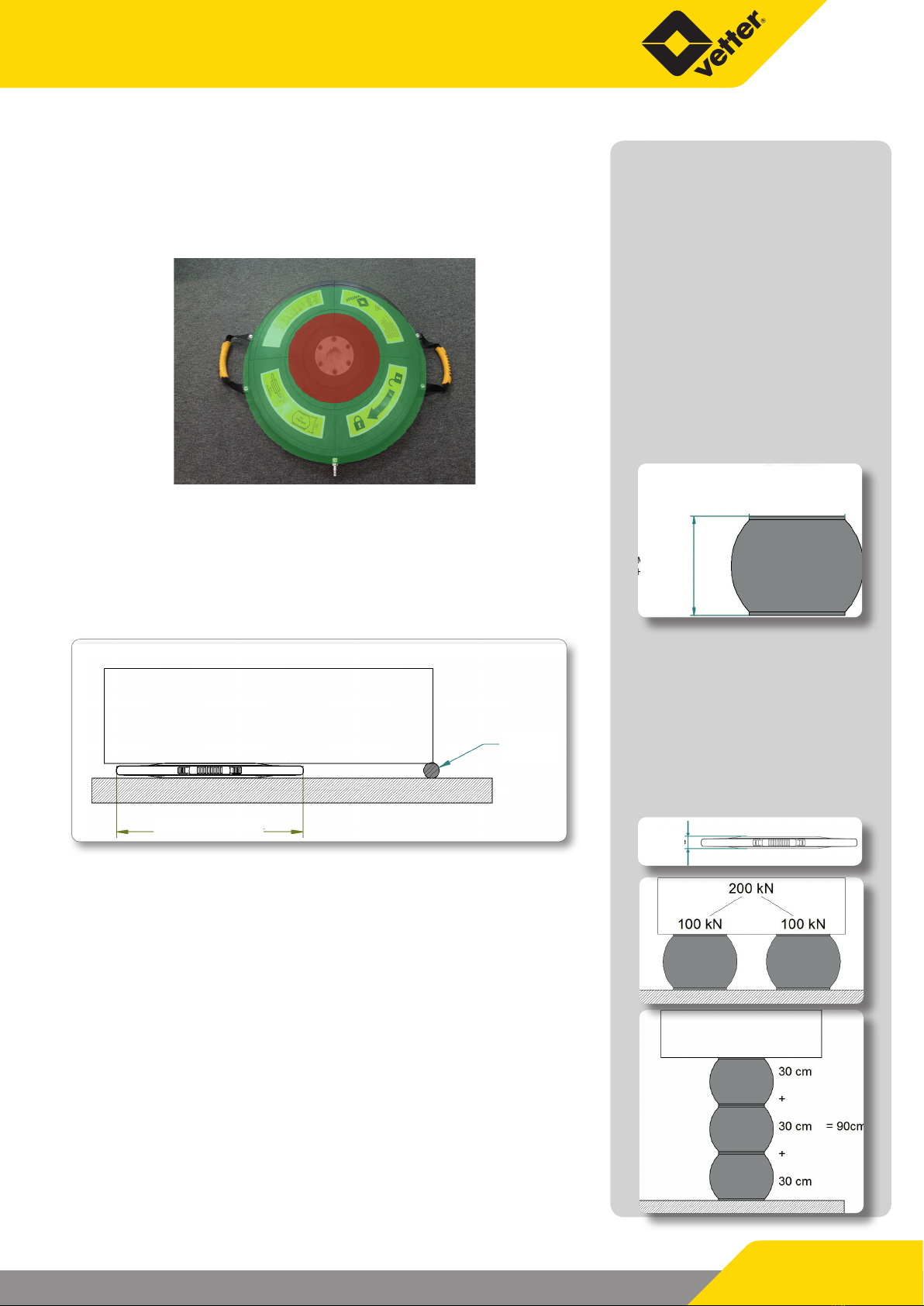

d. Controller 12 bar

When lling and deating of the bags, the

manometer and the load must be observed.

Air CU (Control Unit) 12 bar deadman

Connect the ination hoses on the output couplings on the rear

side of the controller. Connect the air suppply to the input coup-

ling on the side. Move the switching lever towards you in order

to inate the C.Tec Bag. In doing this, observe the corresponding

manometer and the movement of the load. When the required

operating pressure for the lifting power or lift height is reached,

terminate the ination sequence by releasing the lever. Latest

when the safety valve blows o or the red marking is reached!

The switching lever automatically returns back to the zero posi-

tion (dead-man switching). The integrated safety valve activates

automatically as soon as the maximum operating pressure of 12

bar is exceeded when inating or when there is a sudden increase

in bag pressure caused by an unintended loading of the bag.

The activation tolerance for opening and closing of the

safety valve must only be a maximum of +/- 10%.

Press the switching lever in the opposite direction in order to de-

ate the bag or to lower the load.

The lighting of the control element illuminates all couplings,

switch levers and manometers. It is switched on and o with

switch (1) on the side.

The control element is supplied by a 9 V block battery. Since the

entire lifting bag system is designed for a temperature range of

-20 °C to +55 °C, only batteries with this temperature range are

allowed to be used. Based on the current state of the art, only li-

thium batteries meet this requirement.

To insert the battery, unscrew the battery compartment, replace

the old battery with a new one and screw the battery compart-

ment back together.

Control elements with lighting come under the German Law on

electrical and electronic devices (ElektroG) of 24 March 2005 for

implementation of the EC Directive 2002/96/EC on electrical and

electronic waste – WEEE Directive.

The label attached to the battery compartment cover points

out that the electronic components in this product must not be

handled as domestic waste; they have to be returned to the ma-

nufacturer (return freight paid) for recycling.

1

Dierent couplings!