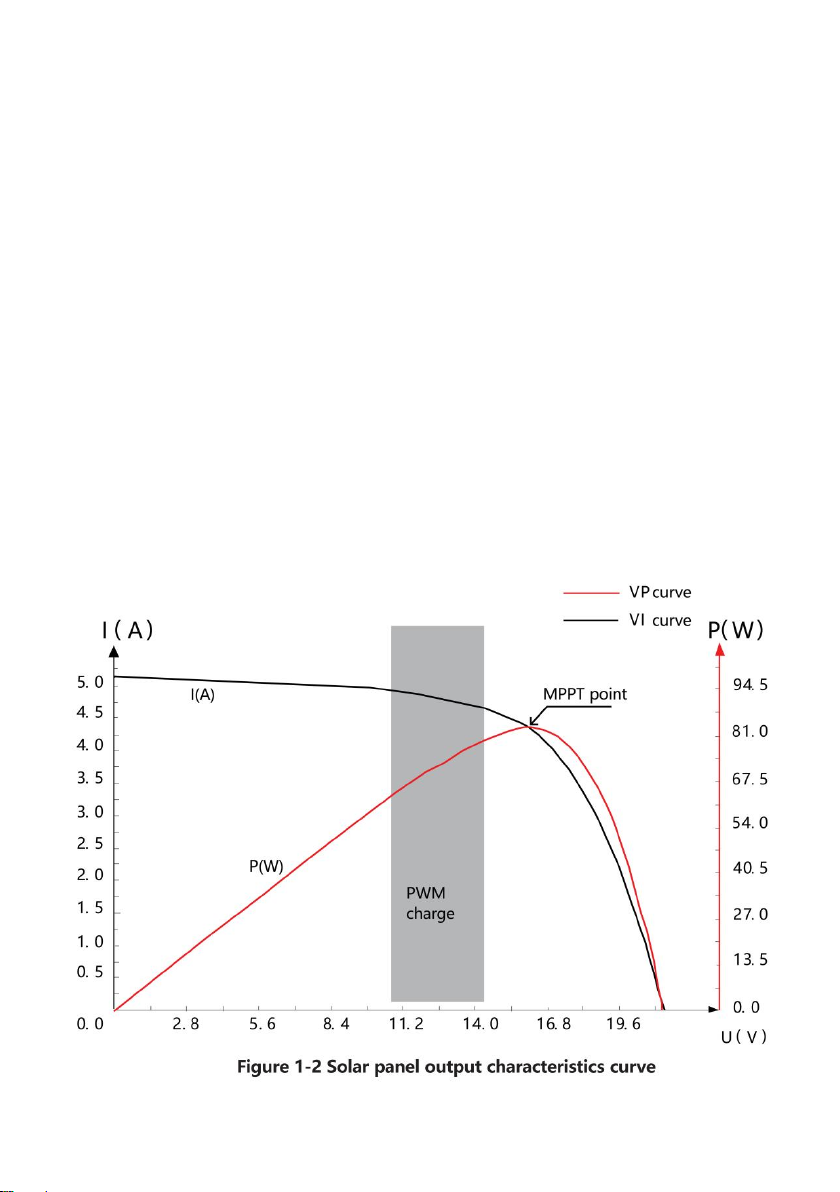

system, which is about 15% to 20% higher than traditional PWM

charging.

It provides an active charging voltage regulation feature. At battery

open circuit or lithium battery BMS overcharge protection, the

controller battery terminal will output the rated charging voltage value.

MPPT tracking efficiency is up to 99.9%.

Due to advanced digital power technology, the circuit energy

conversion efficiency is as high as 98%.

Available in multiple battery types and support charging procedures of

various types of batteries such as lithium battery, colloidal battery,

sealed battery, vented battery, lithium battery, etc.

A current-limited charging mode is available. When the power of solar

panel is too large and the charging current is higher than the rated

valve, the controller automatically reduces the charging power so that

the solar panel can operate at the rated charging current.

Support automatic identification of lead-acid battery voltage.

External LCD screen or Bluetooth module can be connected for

viewing of equipment operating data and status, and modification of

controller parameters is supported.

Optional built-in Bluetooth function, which can view the running data

and status of equipment and support the change of controller

parameters.

Optional built-in CAN function, which can view the running data and

status of equipment and support the change of controller parameters.

Support standard Modbus protocol to meet communication needs in

different occasions.

Built-in over-temperature protection mechanism ensures that when

temperature exceeds the set value of the device, the charging current

decreases linearly with the temperature, thereby reducing the

temperature rise of controller and avoiding high temperature damage.

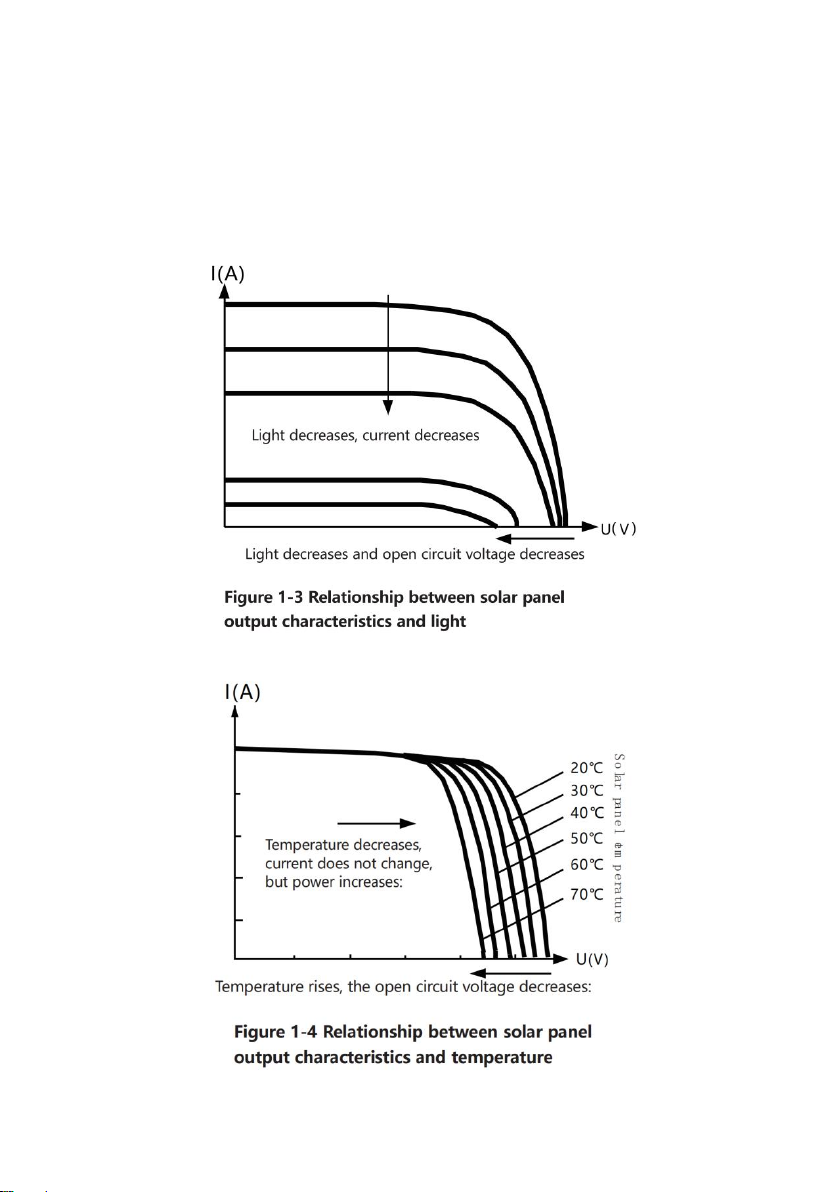

Temperature compensation and automatic adjustment of charge and

discharge parameters help to improve battery life.

Solar panel short circuit protection, battery open circuit protection and

TVS lightning protection, etc.