9.USESAFETYGLASSES.Alsouseafaceandadustmasktoguardagainstdust

10.DONOTABUSETHECORD.Nevercar

Keepthecordaway fromheat,oilorsharpobjects.

11.SECUREYOURWORK.Useclampsoravicetoholdyourworkinposition.Itismuchsaferthanusing

yourhandanditfreesbothhandstooperatethetool.

12.DONOTOVERREACH.Keepproperfootingandbalanceatalltimes.

13.MAINTAINTOOLSWITHCARE.Keeptoolscleanforbetterandsaf

forlubricatingandchangingaccessories.K

14.DISCONNECTTOOLS.Whennotinuse,befor

15.REMOVEADJSUTINGKEYSANDWRENCHES.Havethehabittocheckandseethatkeysand

adjustingwrenchesareremovedfromthetoolbeforeturningiton.

16.AVOIDUNINTENTIONALSTARTING.Donotcar

theswitchisoffwhenpluggingin.

17.OUTDOOREXTENSIONCORDS.Whenthetoolisusedoutdoors,only useextensioncordsintended

foruseoutdoorsandsomarked.

18.STAYALERT.Watchwhatyouaredoing.Usecommonsense.Donotoperatethetoolwhenyou

aretired.

19.CHECKDAMAGEDPARTS.Beforeusingatool,protectivecover,orotherdamagedp

becarefully checkedtoensurethatthetoo

alignmentofmovingp

conditionthatmay affectthetool’soperation.

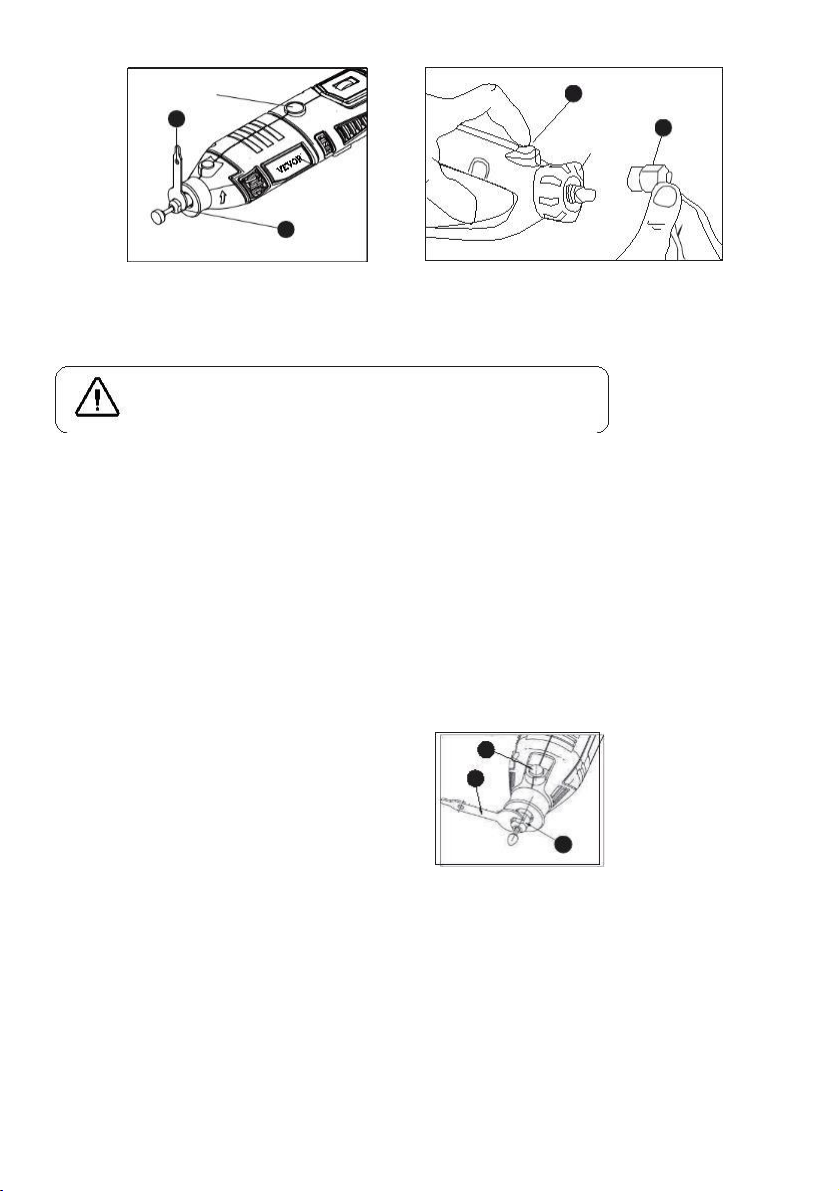

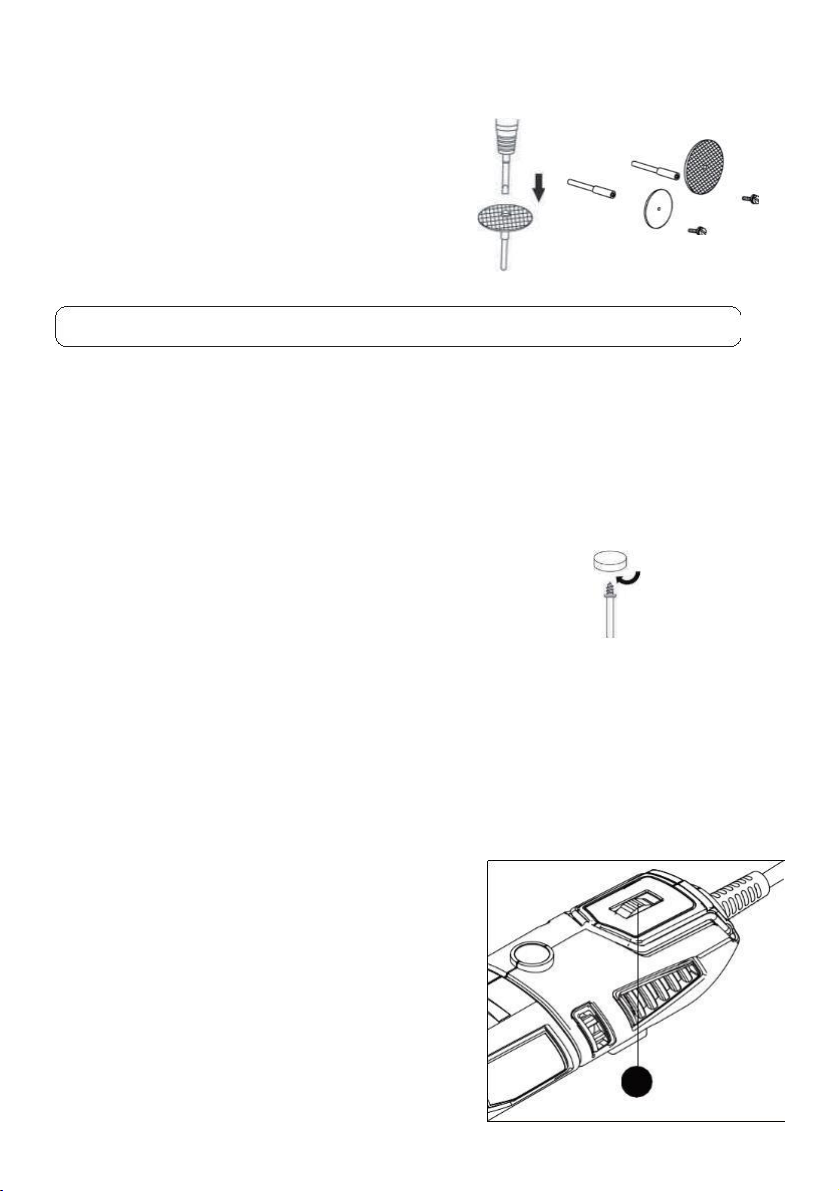

Themultifunctionpowertoolisequippedwithspeedcontrol.Donotchangethespeedwhilethetoolis

working.Thespeedswitchislocatedontherearofthetool.Turnittoincreaseorreducespeed.

Usethetoolatlowspeedforpolishingandsimilaroperations,butusehigherspeedfordrillingor

cuttingaction.

1.Thetoolshouldbeunpluggedwhenchangingaccessories.

2.Ifyoustallthetool,switchitoffimmediately.

3.Periodically checkthetightnessofyourcolletchuck,especially duringprolongeduseofthe

sameacces

4.Afteruse,alwaysdisconnectyourpowertool.

5.Dono