IMPORTANT SAFETY INSTRUCTIONS

CAUTION - To reduce risk of electrical shock or electrocution:

- Donotdisassemble.Donotattemptrepairsormodications.Refertoqualiedservice

agenciesforallserviceandrepairs.

- Donotusethisproductinorareawhereitcanfallorbepulledintowaterorotherliquid.

- Donotreachforthisproductifithasfallenintoliquid.

- Usethiscompressorwith12-voltDCsystemsonly.

- Thisproductshouldneverbeleftunattendedduringuse.

WARNING - To prevent injury:

- Neverallowchildrentooperatethiscompressor.Closesupervisionisnecessarywhenthis

compressor is being used near children.

- Thiscompressorwillbecomeveryhotduringandimmediatelyafteruse.Donottouchanypartof

this compressor with bare hands, other than the ON/OFF switch, during and immediately after use.

- Donotusethisproductnearamesorexplosivematerialsorwhereaerosolproductsarebeingused.

- Donotoperatethisproductwhereoxygenisbeingadministered.

- Do not pump anything other than atmospheric air.

- Neverusethisproductwhilesleepyordrowsy.

- Donotuseanytoolsorattachmentswithoutrstdeterminingmaximumairpressureforthat

tool or attachment.

- Neverpointanyairnozzleorairsprayertowardanotherpersonoranypartofthebody.

- ThisaircompressorisequippedwithAutomaticResetThermalProtector,andcanautomatically

restartafterthethermalprotectorresets.Alwayscutoffpowersourcewhenthermalprotector

becomesactivated.

- Wear safety glasses or goggles when operating this product.

- Useonlyinwellventilatedareas.

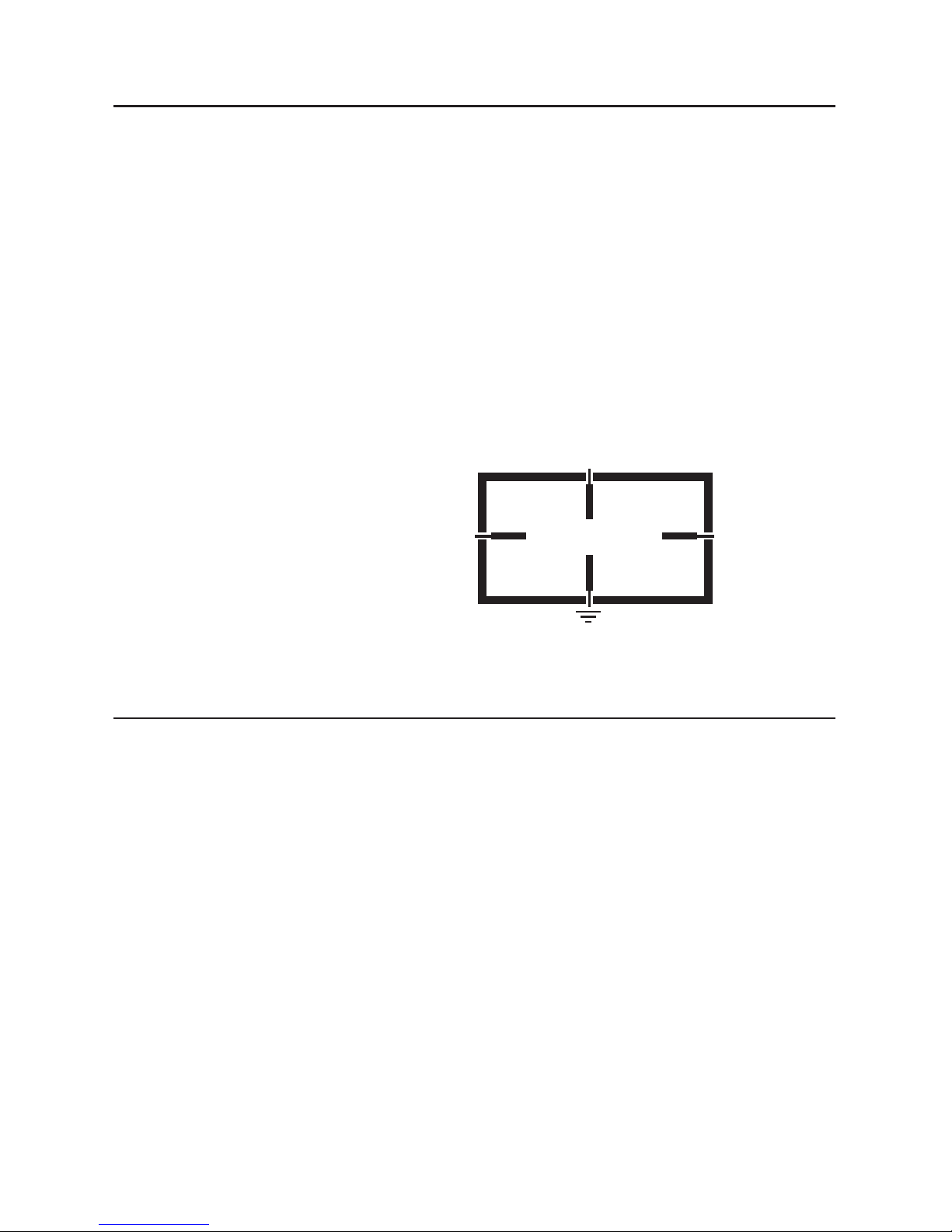

INSTALLATION

Pleasereadandfollowtheinstallationinstructionscarefullytoavoidinjuryordamagetothe

compressororyourvehicle.Eachofouraircompressorsandpartshavebeencarefullyproduced

andpackaged.Beforeyoubegininstallation,pleasefamiliarizeyourselfwithInstallationPartsList

(Fig. 1) of this manual.

Guidelines for Selecting Mounting Location:

The selection of proper mounting location for your air compressor will help ensure a long and

troublefreecompressorservicelife.Pleasepay close attention to the following guidelines:

1. Select a FLAT,UPRIGHTANDSECURE location where the compressor can be mounted.

2.Tomaximizeaircompressorperformance,locatecompressorasCLOSETOTHEBATTERY

aspossiblesothatlengthofpositiveleadwirerequiredisataminimum.

3.ChoosemountinglocationthatisascoolaspossibleandAWAYFROMHEATSOURCES.

Thecoolertheambienttemperaturethelesschancethecompressorwilloverheat.

4. This compressor is moisture & splash resistant, but NOTWATERPROOF. Do not mount

compressor in locations where the unit is likely to come in contact with water.

5. Select compressor mounting location where air line can be routed from compressor air inlet

toremoteinletairlter.MakesureRemoteInletAirFilterislocatedinadrylocation,away

from water splashes.

6.Youwillalsowanttoselectcompressor’smountinglocationwheretheleaderhosebracket

can be mounted to secure the 1.5 ft. leader hose.

7. If it is necessary to mount the air compressor farther away from the battery, such as

insideyourvehicleorinthebedofyourpickup,useaminimum16AWGpositiveleadwire

for remote installation.

8.Donotmountcompressornearareaswhereammableliquidsarestored.

9.Usethreadsealantforproperttinginstallation.Teontapeisnotrecommended.

Properlysealed,recommendedtorqueis12to15ft.lbs

USER MANUAL

280C Air Compressor Kit