1

NM & PG PLUS FID TOWERS

USER MANUAL

Version 1.03.0000

www.vicidbs.com

TABLE OF CONTENTS

1. VERSION HISTORY................................................................................................................................ 2

2. INTRODUCTION.................................................................................................................................... 3

2.1. Symbol Denitions...............................................................................................................................3

3. SAFETY.................................................................................................................................................. 4

3.1. Personal Safety Instructions.................................................................................................................4

3.2. Instrument Safety Instructions ............................................................................................................4

4. SPECIFICATIONS................................................................................................................................... 5

4.1. Common Options................................................................................................................................6

4.1.1. Remote Connections...................................................................................................................6

4.1.2. Cascading ...................................................................................................................................6

5. PRESENTATION OF THE DEVICE.......................................................................................................... 8

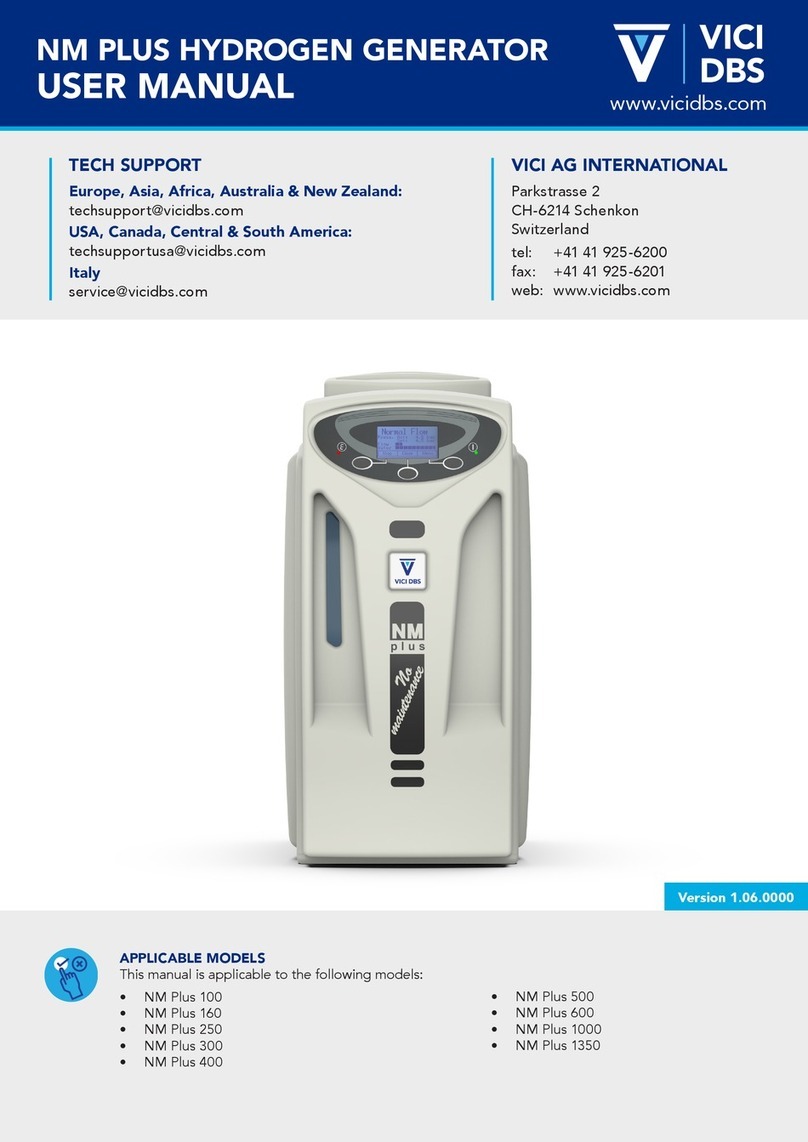

5.1. Front View............................................................................................................................................8

5.2. Back View ............................................................................................................................................9

5.3. Dimensions........................................................................................................................................ 10

5.4. Weight............................................................................................................................................... 10

5.5. Transport and Storage ...................................................................................................................... 11

5.6. Fuses and Voltage Settings............................................................................................................... 12

5.7. Schematics......................................................................................................................................... 13

5.7.1. Fluids ......................................................................................................................................... 13

5.7.2. Electronics ................................................................................................................................ 16

6. INSTALLATION AND INITIAL START-UP ............................................................................................. 19

6.1. Receiving the Generator.................................................................................................................... 19

6.2. Included in Shipment/Packing List.................................................................................................... 19

6.3. Installing the Generator ....................................................................................................................20

6.4. Gas Connections...............................................................................................................................20

6.5. Electrical Connections ...................................................................................................................... 21

6.6. Filling the Water Tank........................................................................................................................22

6.7. Installing the Deionizer Bag............................................................................................................... 23

6.8. Starting the Hydrogen Generator..................................................................................................... 24

6.9. Turning Off the Generator.................................................................................................................24

6.10. Starting the Zero Air Generator ......................................................................................................25

7. OPERATION - HYDROGEN PART ........................................................................................................ 26

7.1. LCD Display.......................................................................................................................................26

7.1.1. Layout of the Display................................................................................................................26

7.1.2. First Row - Status Information ..................................................................................................26

7.1.3. Second Row - Pressure Information .........................................................................................26

7.1.4. Third Row - Hydrogen Flow .....................................................................................................27

7.1.5. Fourth Row - Water Quality......................................................................................................27

7.1.6. Start/Stop - Reset Button ......................................................................................................... 27

7.1.7. Exit - Menu Button ...................................................................................................................27