Contents

Chapter 1 Safety and Precautions .................................................... - 1 -

1.1 Safety Precautions .............................................................. - 1 -

Chapter 2 Product Information ....................................................... - 3 -

2.1 Designation Rules .............................................................. - 3 -

2.2 Nameplate..................................................................... - 3 -

2.3 Inverter Series ................................................................. - 3 -

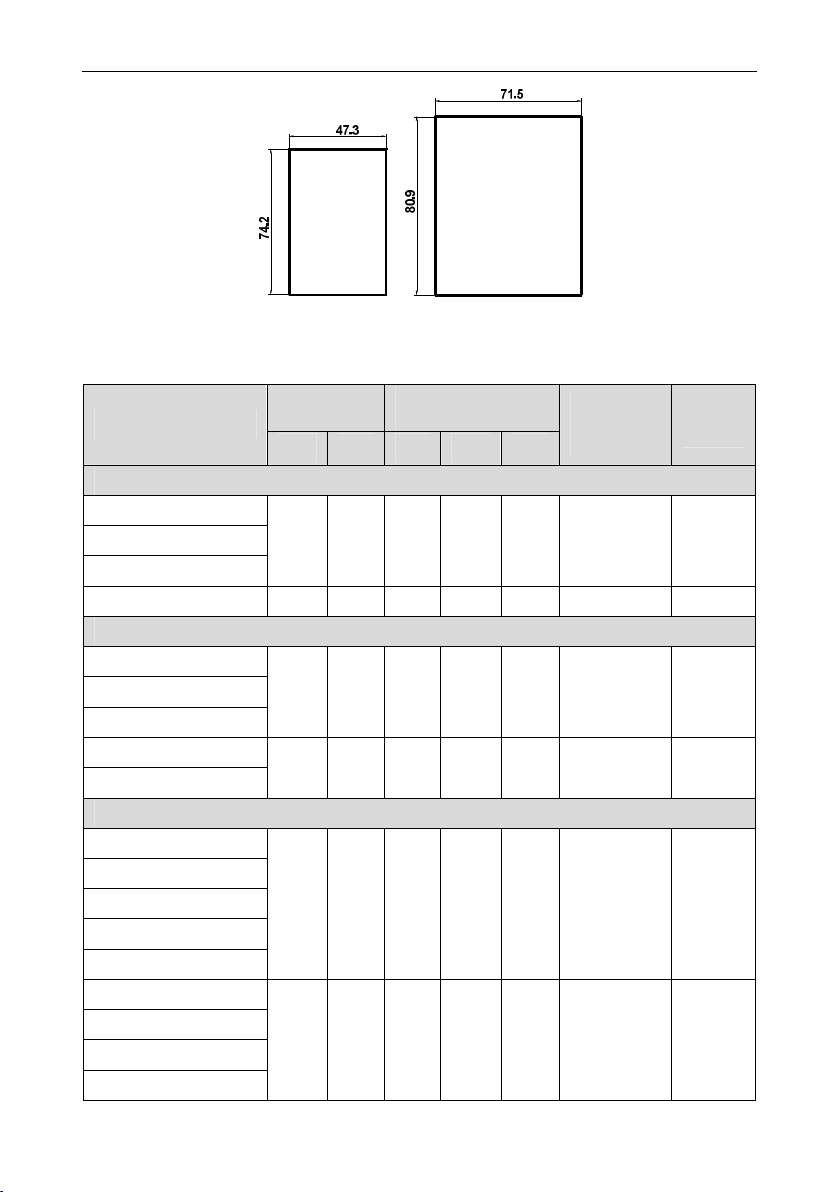

2.4 Product Appearances and Installation Dimension .................................... - 4 -

2.5 Recommended Brake Resistor Selection Table ...................................... - 7 -

2.6 Warranty Introduction............................................................ - 7 -

Chapter 3 Mechanical and Electrical Installation ........................................ - 8 -

3.1 Standard Wiring Diagram ........................................................ - 8 -

3.2 Main Circuit Terminals ........................................................... - 8 -

3.3 Control Circuit Terminal .......................................................... - 9 -

Chapter 4 Operation and Display ....................................................- 12 -

4.1 Introduction to Operation and Display Interface.....................................- 12 -

Chapter 5 Function Parameter Table ................................................. - 14 -

Chapter 6 Parameter Description .................................................... - 64 -

F0 Basic Function.................................................................- 64 -

F1 Start/Stop Control Group ........................................................ - 71 -

F2 Motor 1 Parameter ............................................................. - 77 -

F3 Motor 1 Vector Control Parameter ................................................ - 79 -

F4 Motor 1 V/F Control Parameter ................................................... - 82 -

F5 Input Terminal Group ........................................................... - 86 -

F6 Output Terminal Function Group .................................................. - 98 -

F7 Keyboard and Display Function Group ........................................... - 103 -

F8 Protection Parameters ......................................................... - 107 -

F9 Fault Record and Setting Parameter Group ....................................... - 110 -

FA Process PID Parameter Group .................................................. - 114 -

Fb Enhance Function Group ....................................................... - 118 -

Fd MODBUS Communication Parameter Group ...................................... - 132 -

FF User Parameters Group........................................................ - 133 -

FP Factory Parameter Group ...................................................... - 135 -

A0 Motor 1 Torque Control Parameter Group ......................................... - 135 -

AI Optimize Control Parameter Group ............................................... - 138 -

b0 User Customize Function Code.................................................. - 141 -

b1 Virtual IO Parameter Group ..................................................... - 142 -

b2 AI Curve Setting Parameter Group ............................................... - 146 -

b3 AIAO Correction Parameter Group ............................................... - 148 -

U0 Basic Monitoring Parameters Group ............................................. - 149 -

Chapter 7 EMC Guide ............................................................ - 151 -

7.1 Definition .................................................................... - 151 -

7.2 EMC Standard Introduction..................................................... - 151 -

7.3 EMC Guide .................................................................. - 151 -

Chapter 8 Fault Shooting and Solutions ............................................. - 153 -

8.1 Fault Alarm and Countermeasures .............................................. - 153 -

8.2 Common Faults and Solutions .................................................. - 157 -