Contents

Chapter 1 Safety and Precautions............................................................................................................- 1 -

1.1 Safety Definition...................................................................................................................................- 1 -

1.2 Safety Precautions...............................................................................................................................- 1 -

1.3 General Precautions............................................................................................................................- 3 -

Chapter 2 Product Information..................................................................................................................- 6 -

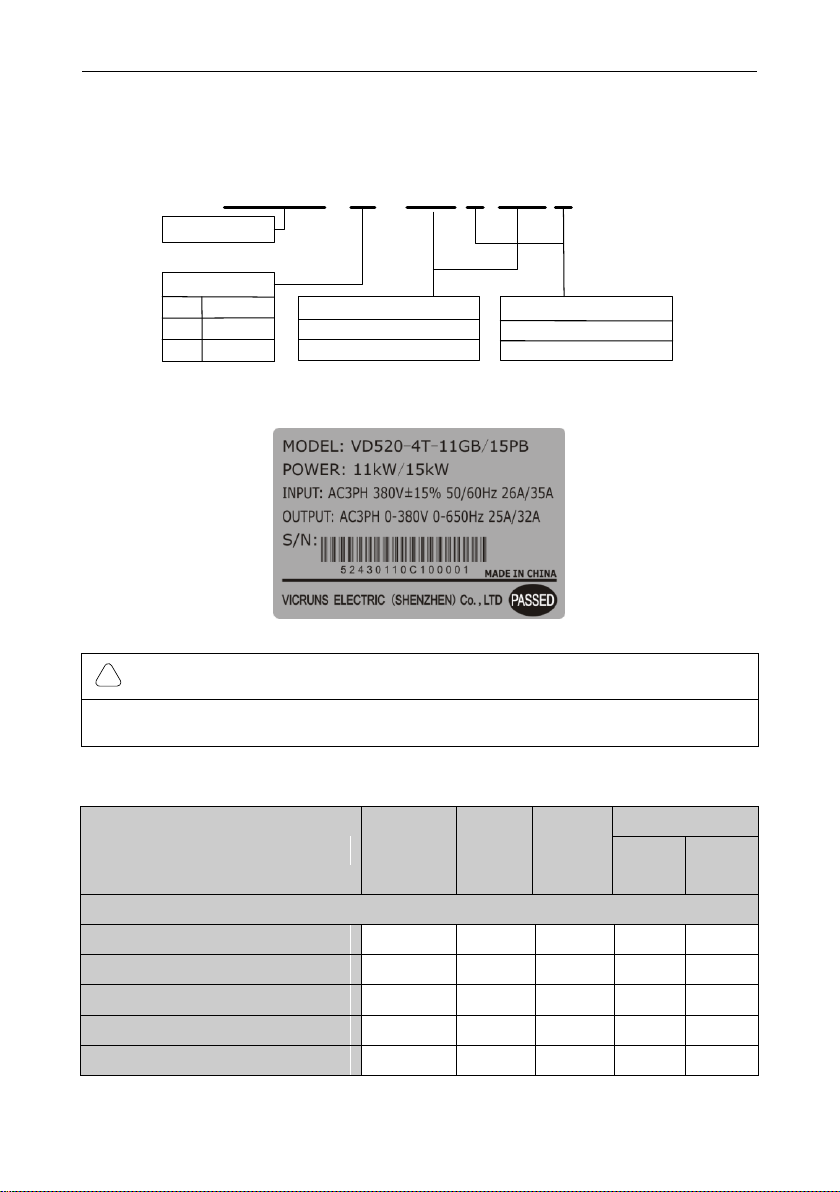

2.1 Designation Rules................................................................................................................................ - 6 -

2.2 Nameplate.............................................................................................................................................- 6 -

2.3 Inverter Series ...................................................................................................................................... - 6 -

2.4 Product Specifications .........................................................................................................................- 8 -

2.5 PhysicalAppearance and Main Structure Diagram........................................................................- 10 -

2.6 ProductAppearance and Installation Dimension............................................................................ - 11 -

2.7 Physical Dimensions of External Keyboard....................................................................................- 13 -

2.8 Braking Unit Model Selection Guide................................................................................................- 14 -

2.9 Routine Repair and Maintenance of Inverter.................................................................................. - 16 -

2.10 Warranty Introduction ......................................................................................................................- 17 -

Chapter 3 Mechanical and Electrical Installation..................................................................................- 18 -

3.1 Installation Environment....................................................................................................................- 18 -

3.2 The Installation Direction and Space............................................................................................... - 18 -

3.3 Removing and Mounting the Cover Plate and Keyboard..............................................................- 19 -

3.4 Inverter and External Electrical Parts Connection.......................................................................... - 20 -

3.5 Standard Wiring Diagram..................................................................................................................- 25 -

3.6 Main Circuit Terminals .......................................................................................................................- 27 -

3.7 Control Circuit Terminal..................................................................................................................... - 30 -

Chapter 4 Operation and Display........................................................................................................... - 38 -

4.1 Introduction to Operation and Display Interface.............................................................................- 38 -

4.2 Motor Parameter Self-learning.......................................................................................................... - 40 -

4.3 Password Setting ............................................................................................................................... - 41 -

4.4 Parameter Lock (authority lower than password)...........................................................................- 41 -

Chapter 5 Function Parameter Table .....................................................................................................- 42 -

Chapter 6 Parameter Description........................................................................................................... - 97 -

F0 Basic Function..................................................................................................................................... - 97 -

F1 Start/Stop Control Group.................................................................................................................. - 105 -

F2 Motor 1 Parameter............................................................................................................................ - 112 -

F3 Motor 1 Vector Control Parameter.................................................................................................. - 114 -

F4 Motor 1 V/F Control Parameter....................................................................................................... - 117 -

F5 Input Terminal Group........................................................................................................................ - 121 -

F6 Output Terminal Function Group.....................................................................................................- 131 -

F7 Keyboard and Display Function Group .......................................................................................... - 136 -

F8 Protection Parameters......................................................................................................................- 140 -

F9 Fault Record and Setting Parameter Group..................................................................................- 144 -

FA Process PID Parameter Group........................................................................................................ - 148 -

Fb Enhance Function Group.................................................................................................................- 153 -

Fd MODBUS Communication Parameter Group................................................................................- 169 -

FF User Parameters Group...................................................................................................................- 170 -

FP Factory Parameter Group................................................................................................................ - 172 -

A0 Motor 1 Torque Control Parameter Group .....................................................................................- 173 -

AI Optimize Control Parameter Group.................................................................................................- 176 -

A2, 3, 4 Motor 2 Parameter Function Group....................................................................................... - 178 -

b0 User Customize Function Code.......................................................................................................- 179 -

b1 Virtual IO Parameter Group .............................................................................................................- 180 -

b2 AI Curve Setting Parameter Group................................................................................................. - 184 -

b3 AIAO Correction Parameter Group .................................................................................................- 186 -

U0 Basic Monitoring Parameters Group.............................................................................................. - 188 -