TSUBAKIMOTO CHAIN CO.: hereinafter referred to as “Seller”

Customer: hereinafter referred to as “Buyer”

Goods sold or supplied by Seller to Buyer: hereinafter referred to as “Goods”

1. Warranty period without charge

18 months effective the date of shipment or 12 months effective the first

use of Goods, including installation of Goods to Buyer’s equipment or

machines - whichever comes first.

2. Warranty coverage

Should any damage or problem with the Goods arise within the warranty

period, given that the Goods were operated and maintained under

instructions provided in the manual, Seller would repair and replace at no

charge once the Goods are returned to Seller. The following are excluded

from the warranty.

1) Any costs related to removing Goods from the Buyer’s equipment or

machines to repair or replace parts.

2) Costs to transport Buyer’s equipment or machines to the Buyer’s

repair shop.

3) Costs to reimburse any profit loss due to any repair or damage and

consequential losses caused by the Buyer.

3. Warranty with charge

Seller will charge any investigation and repair of Goods caused by:

1) Improper installation by failing to follow the instruction manual.

2 )Insufficient maintenance or improper operation by the Buyer.

3) Incorrect installation of Goods to other equipment or machines.

4) Any modifications or alterations of Goods by the Buyer.

5) Any repair by engineers other than the Seller or those designated by the

Seller.

6) Operation in an inappropriate environment not specified in the manual.

7) Force Majeure or forces beyond the Seller’s control such as natural

disasters and injustice done by a third party.

8) Secondary damage or problem incurred by the Buyer’s equipment or

machines.

9) Defected parts supplied, or specified by the Buyer.

10) Incorrect wiring or parameter setting by the Buyer.

11) The end of life cycle of the Goods under normal usage.

12) Loss or damage not liable to the Seller.

4. Dispatch Service

Service to dispatch a Seller’s engineer to investigate, adjust or trial test

Seller’s Goods is at the Buyer’s expense.

5. Disclaimer

1) In our constant efforts to improve, TSUBAKIMOTO CHAIN may change

the contents of this document without notice.

2) Considerable effort has been made to ensure that the contents of this

document are free from errors. However, TSUBAKIMOTO CHAIN

makes no warranties with respect to the accuracy of information

described herein. In the mean time, we would appreciate comments or

reports on any inaccuracies or omissions found in this document to help

us make timely amendments as necessary. Your cooperation is greatly

appreciated.

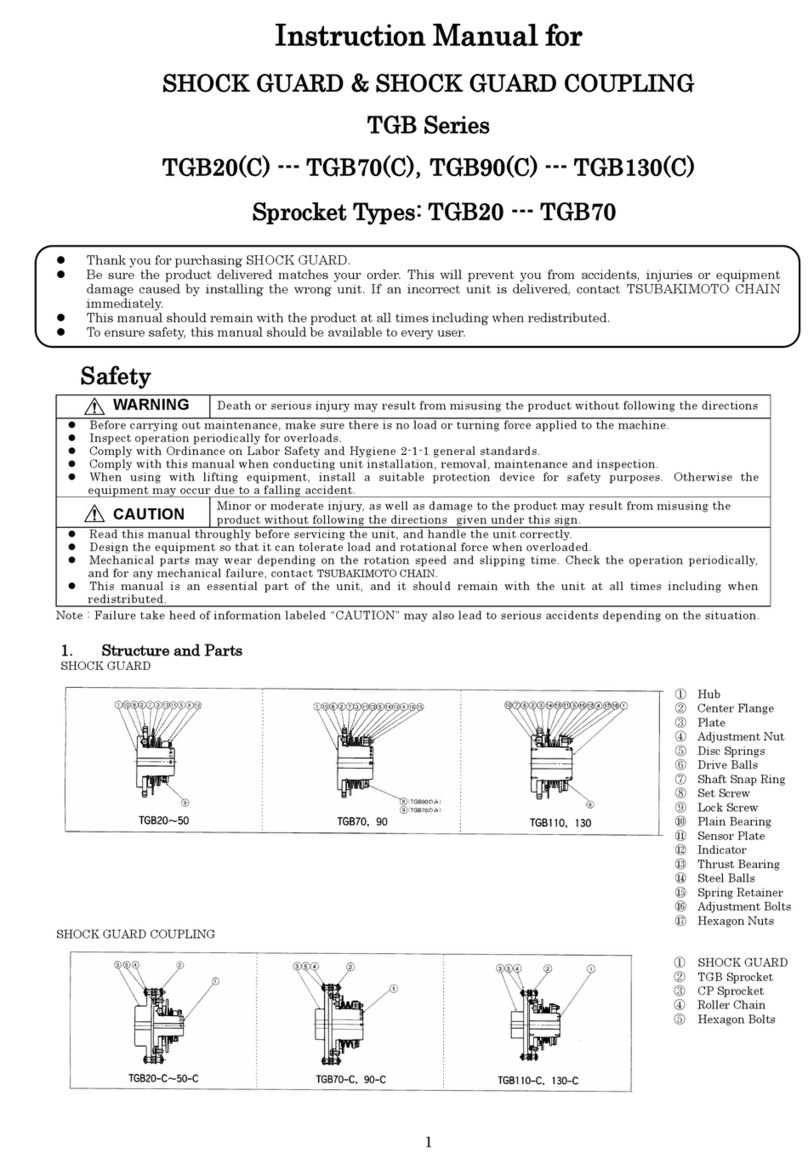

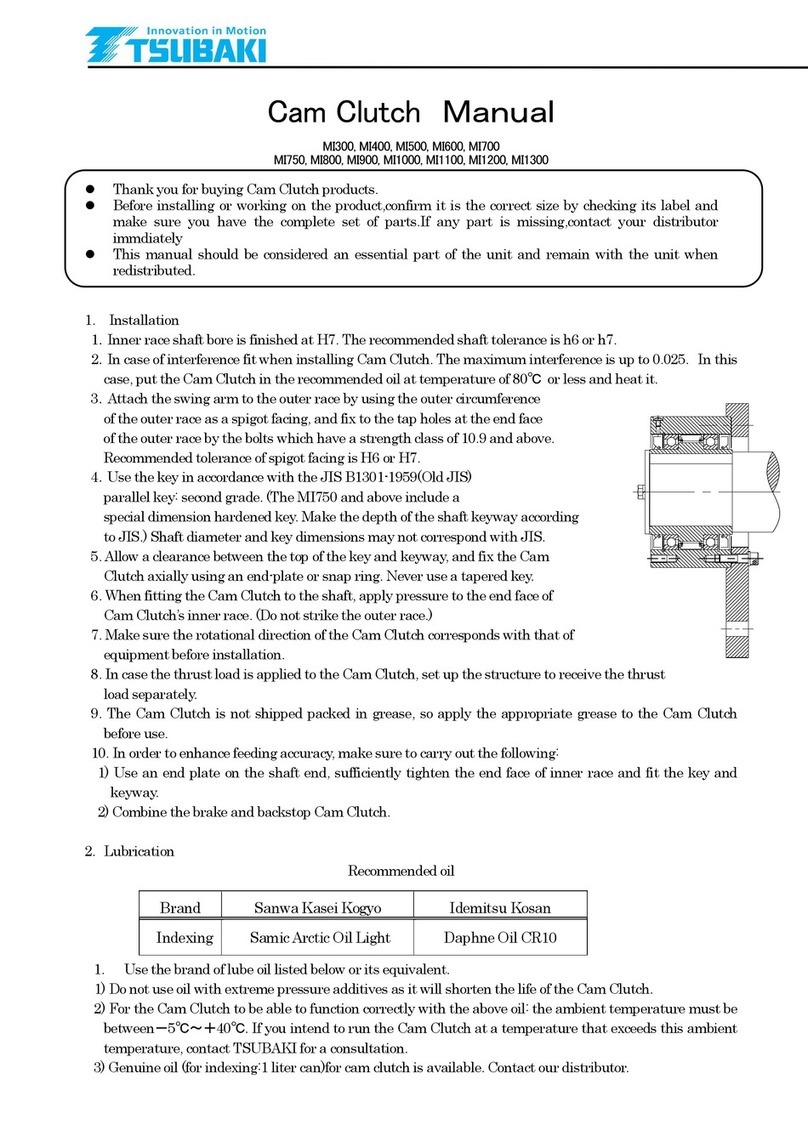

・Sprocket –mounted finished bore Torque Limiter.

Torque is set at 120°on the “Tightening Amount –Torque Correlation Graph”. Set the torque based on 120°with the adjusting nuts or bolts

before use.

5. Tightening method for adjustable nut or bolts

(1)The adjustable nut for TL200, TL250 and TL350 is a hexagon head nut. Tighten it with a spanner wrench to the rated angle then bend the lock

washer to prevent the adjustable nut from loosening.

(2)The adjustable nut for TL500 and TL700 have 3 pcs. of adjustable bolts. Place the pilot plate and disk spring in contact with each other, and

tighten the adjustable nut manually until there is no backlash between their faces. Then retighten the adjustable bolts to the appropriate angle.

6. Replace the friction facing

Change the friction facing when they reach roughly half the thickness of dimension described in the catalog. 1.25 mm for TL200, and 1.6 mm for

TL250~TL700.

Before replacing the friction facing, each part must be completely free of oil, rust and dirt. Also, reassemble the Torque Limiter according to the

structure drawing.

7. Maintenance and precautions after the replacement procedure

The Torque Limiter continues to slip, and the friction facing is abnormally worn or heated unless the driving source is stopped when overloaded.

Stop the driving source immediately in this case, making it necessary to stop the drive source immediately. It allows to automatically stop by

using a digital tachometer and proximity switch. Please refer to the catalogue etc.

Periodically inspect the torque setting, for the initial torque setting may be affected by changes in friction, ambient temperature, humidity and

other conditions.

Replace the friction facing and bushing if they wear. Their replacement parts are in stock.

Keep the Torque Limiter free from water and oil. This will maintain the effectiveness of torque and prevent the equipment or load from falling,

and causing serious accidents.

When sprocket teeth surfaces are induction‐hardened. Lubricating paste should be applied to chain after installation and every 1000 hours.

Refer to the above for assembly of Torque Limiter, torque setting and precaution.

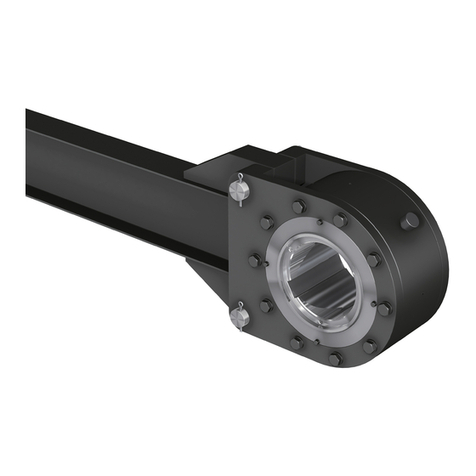

・Installing the Torque Limiter

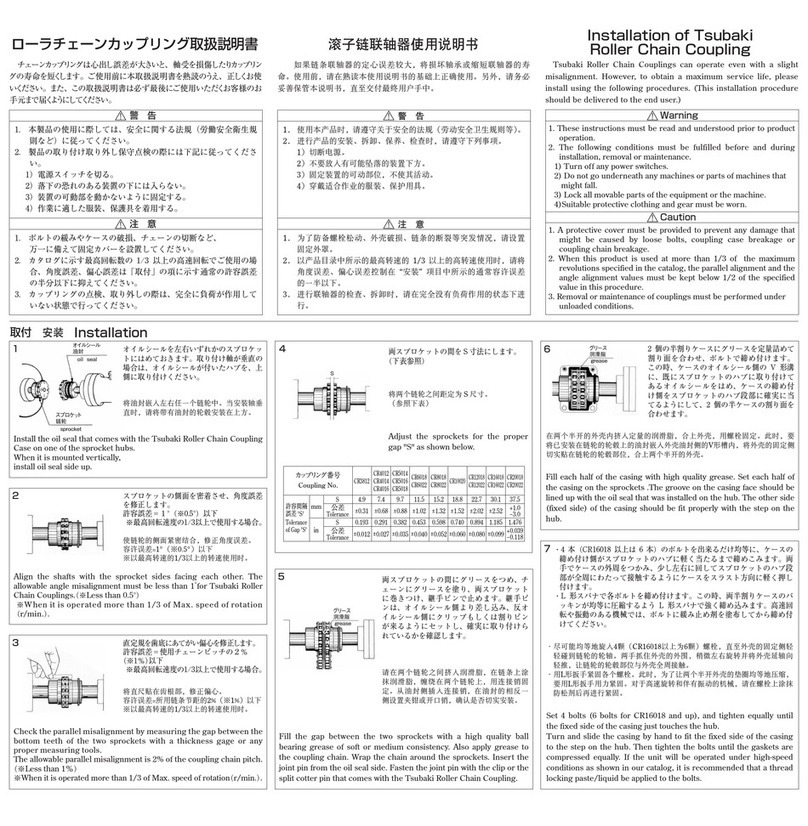

Align the shaft centers by calibrating the angular and parallel misalignments. Measure by placing the scale by the sprocket teeth.

Adjust the length between the sprockets or dimension S, and their parallelism according to the dimensions provided below.

Then wrap the chain around the sprockets and lock with a joint pin.

Max. Angular

Misalignment

Max. Parallel

Misalignment

1-1, Kohtari-Kuresumi, Nagaokakyo

Kyoto 617- 0833, Japan

Website: http://tsubakimoto.com/

DATE 2020/09/09 BulletinNo.05A00TS00E1