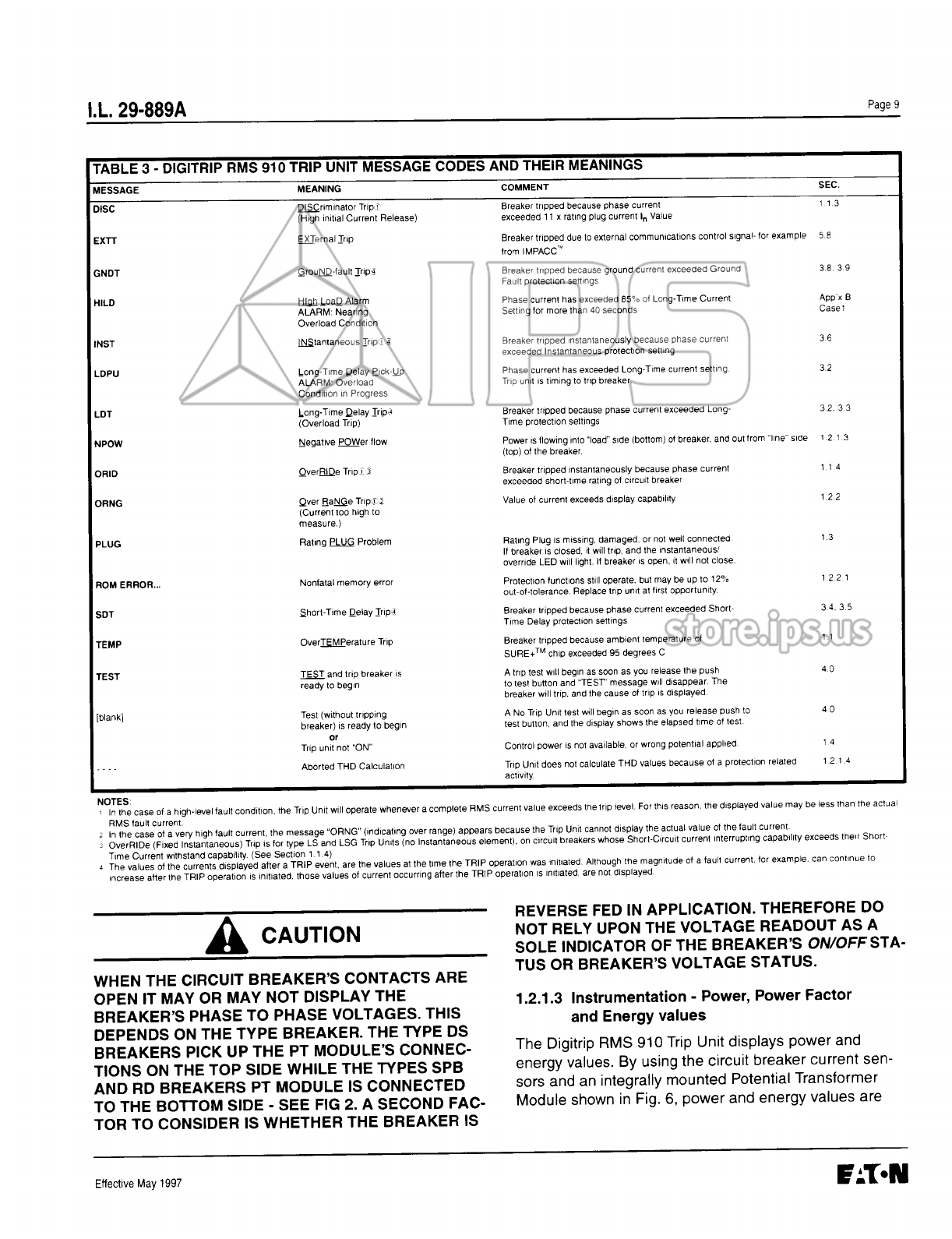

Eaton Digitrip RMS 910 User manual

Other Eaton Industrial Equipment manuals

Eaton

Eaton Airflex CB Guide

Eaton

Eaton CoviO User manual

Eaton

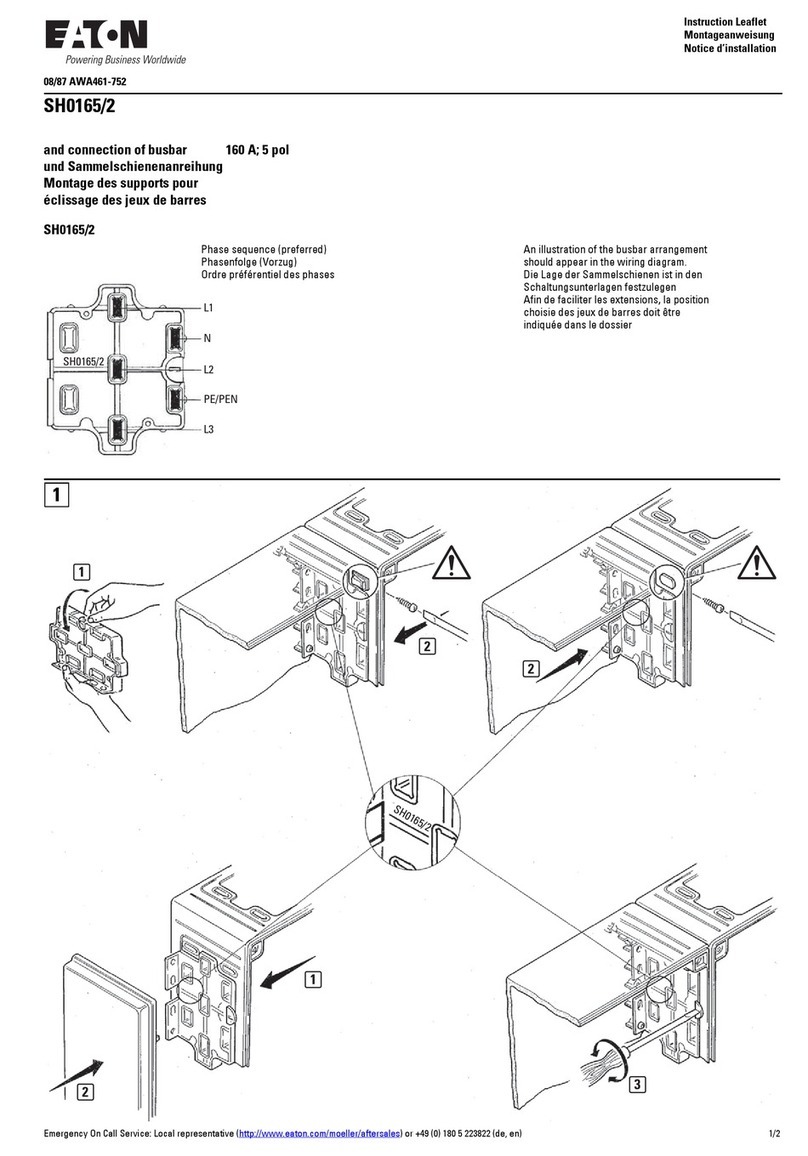

Eaton SH0165/2 Manual

Eaton

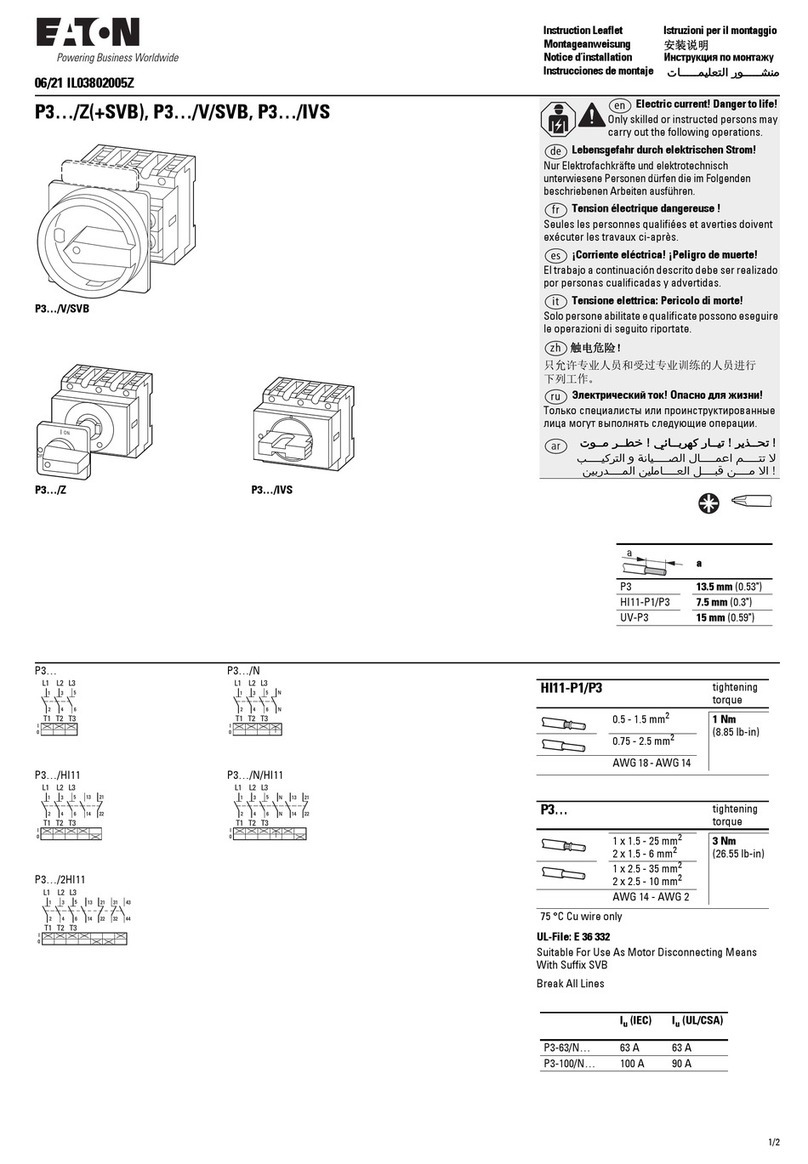

Eaton P3 Series Manual

Eaton

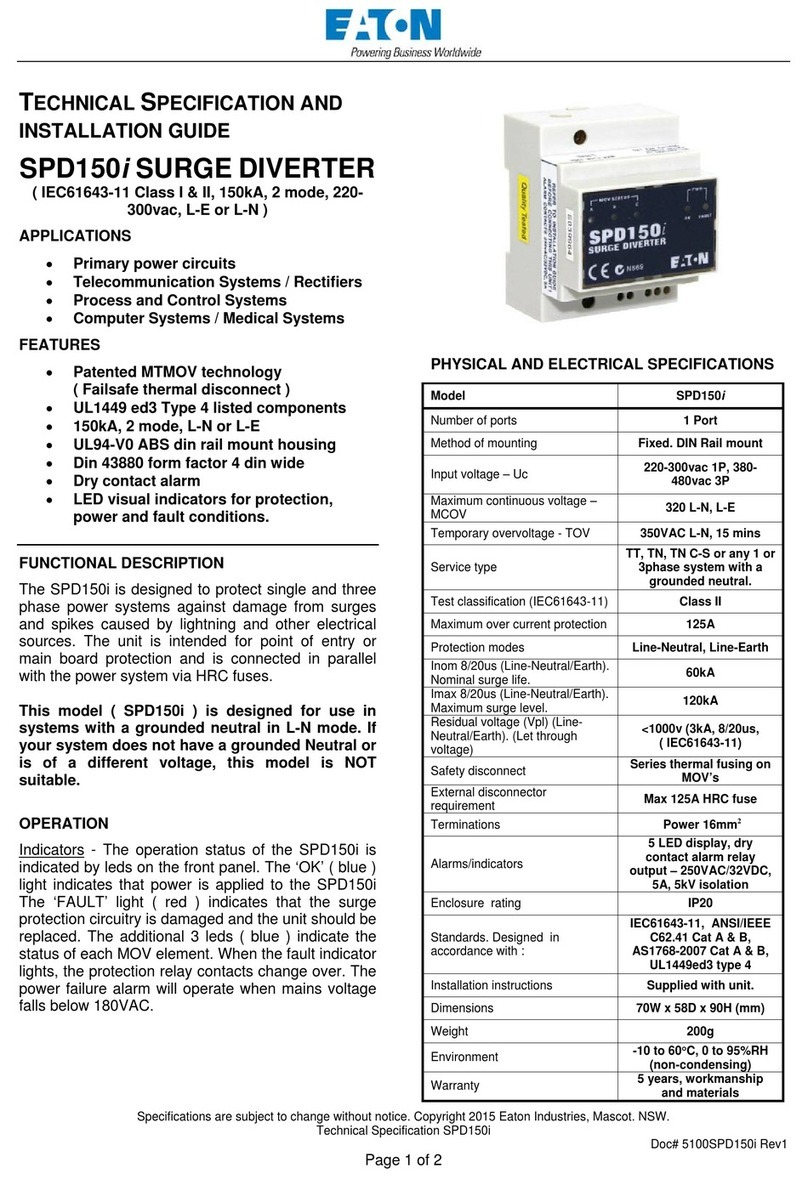

Eaton SPD150i User manual

Eaton

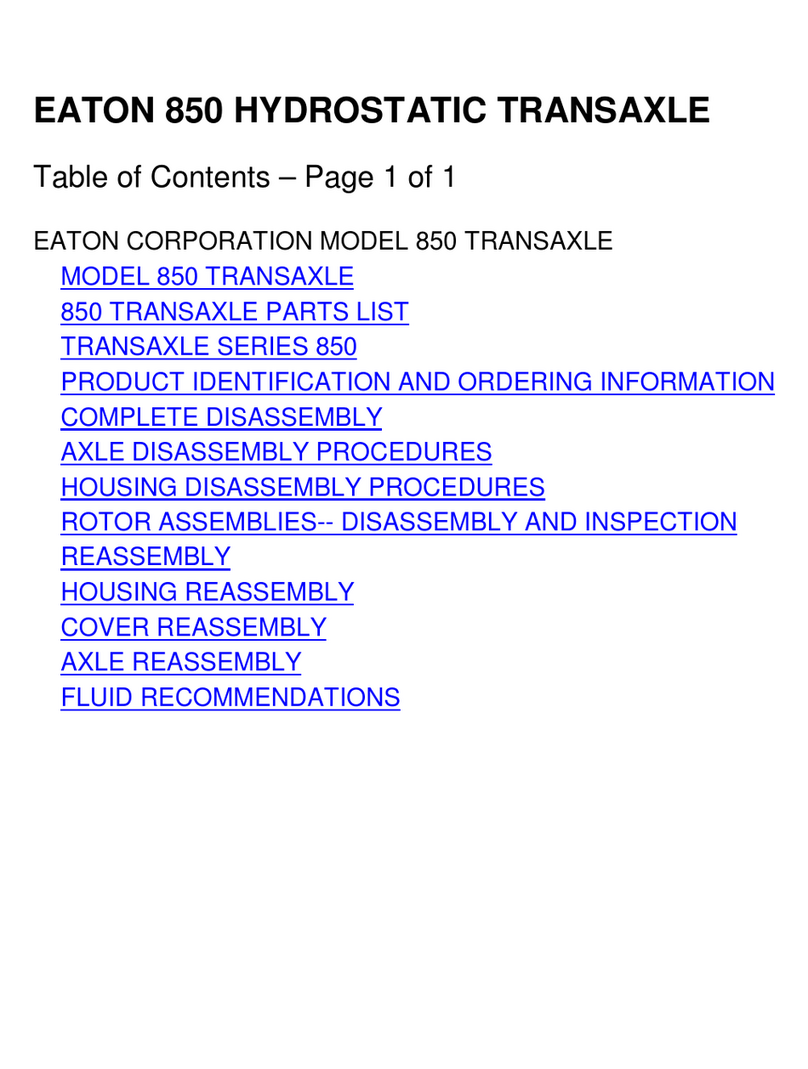

Eaton Hydrostatic Transaxle 850 Series Owner's manual

Eaton

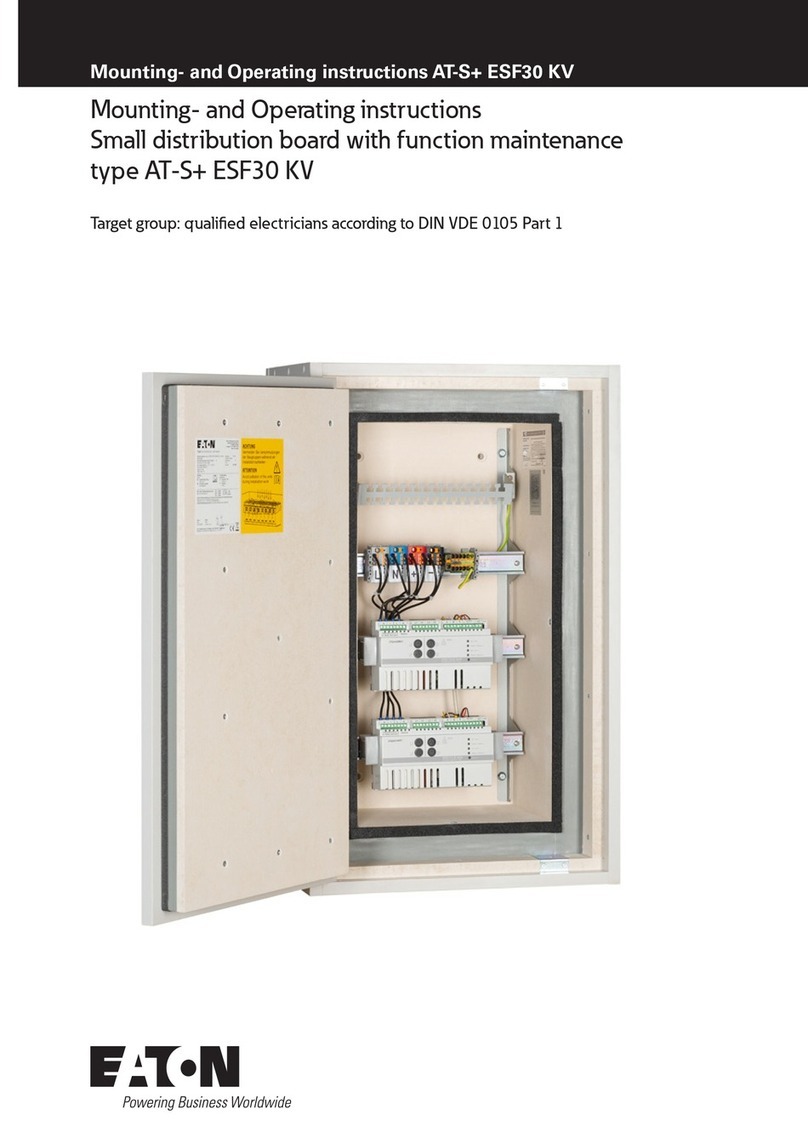

Eaton AT-S PLus ESF30 KV Service manual

Eaton

Eaton Crouse-hinds series User manual

Eaton

Eaton RMQ-Titan C22-PV Series User manual

Eaton

Eaton PDI Revit User manual

Eaton

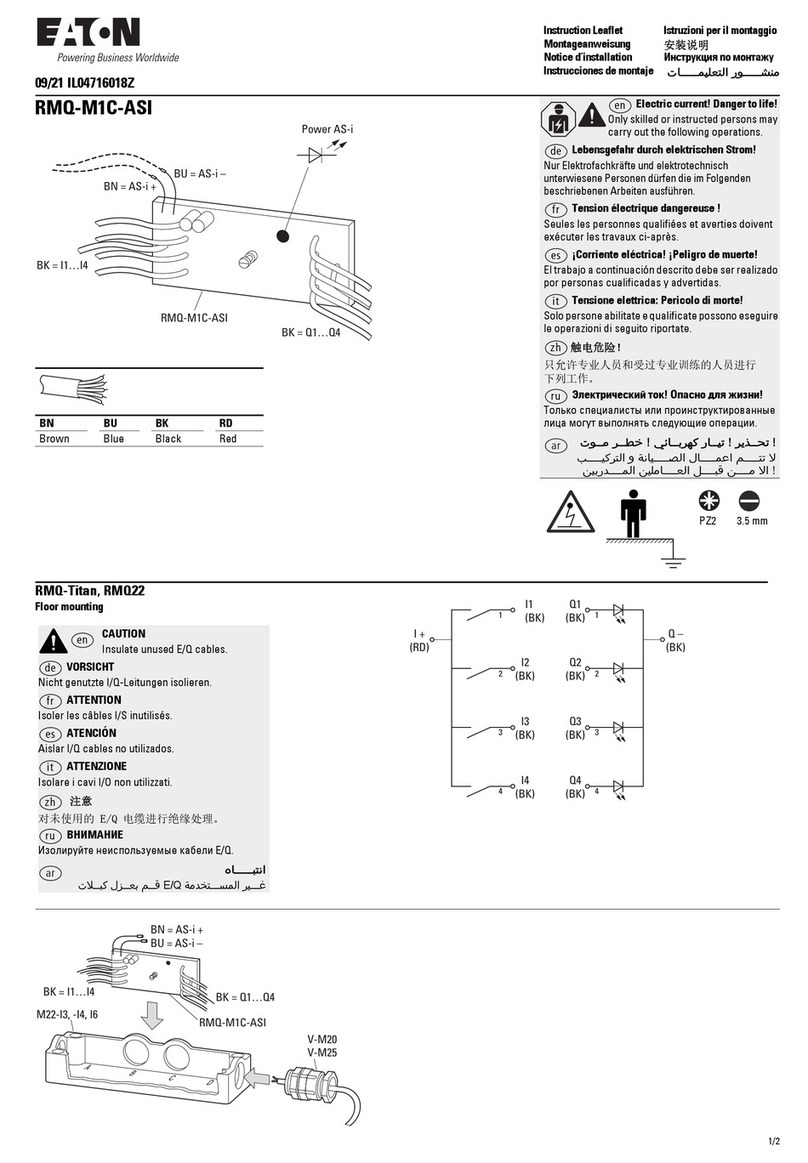

Eaton RMQ-M1C-ASI Manual

Eaton

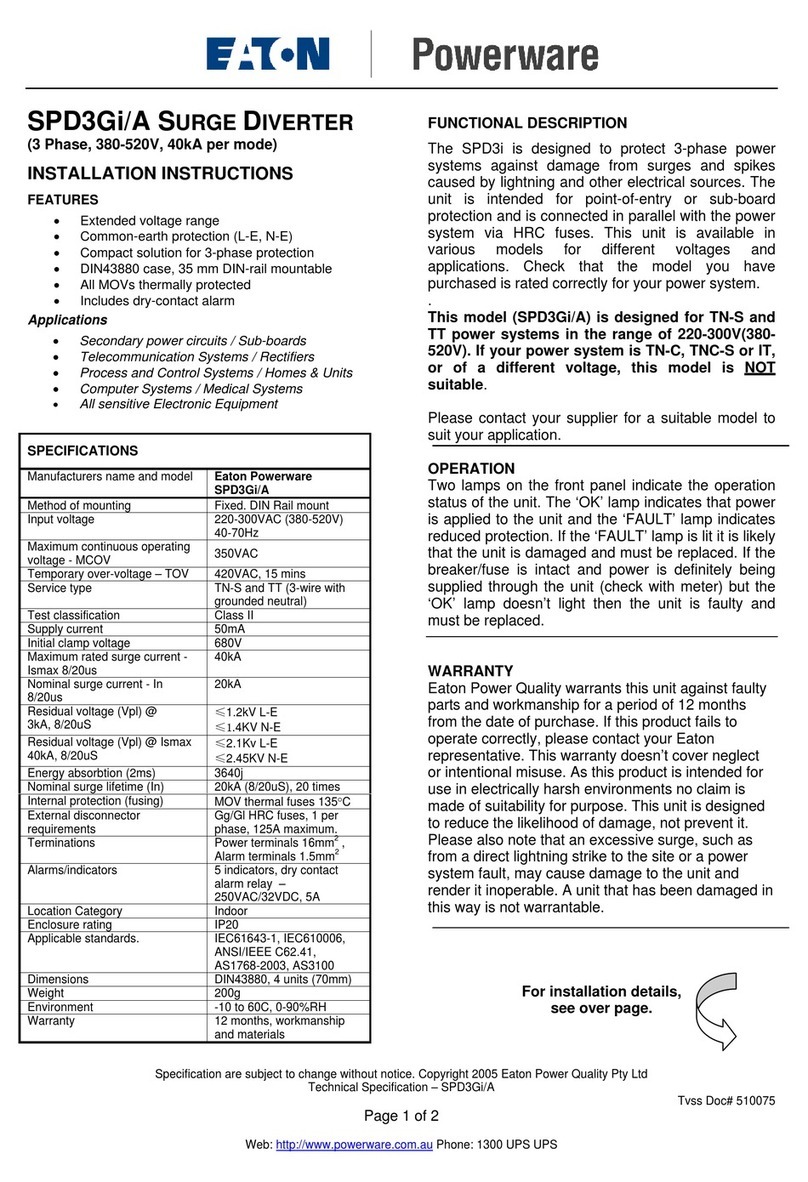

Eaton Powerware SPD3Gi/A User manual

Eaton

Eaton NN-GW-100-LAN User manual

Eaton

Eaton Digitrip Retrofit System Manual

Eaton

Eaton PKE-XTUACP-36 Manual

Eaton

Eaton DDC-63/2/I5 Series Manual

Eaton

Eaton APS3-400 Series Operating instructions

Eaton

Eaton Power Defense Manual

Eaton

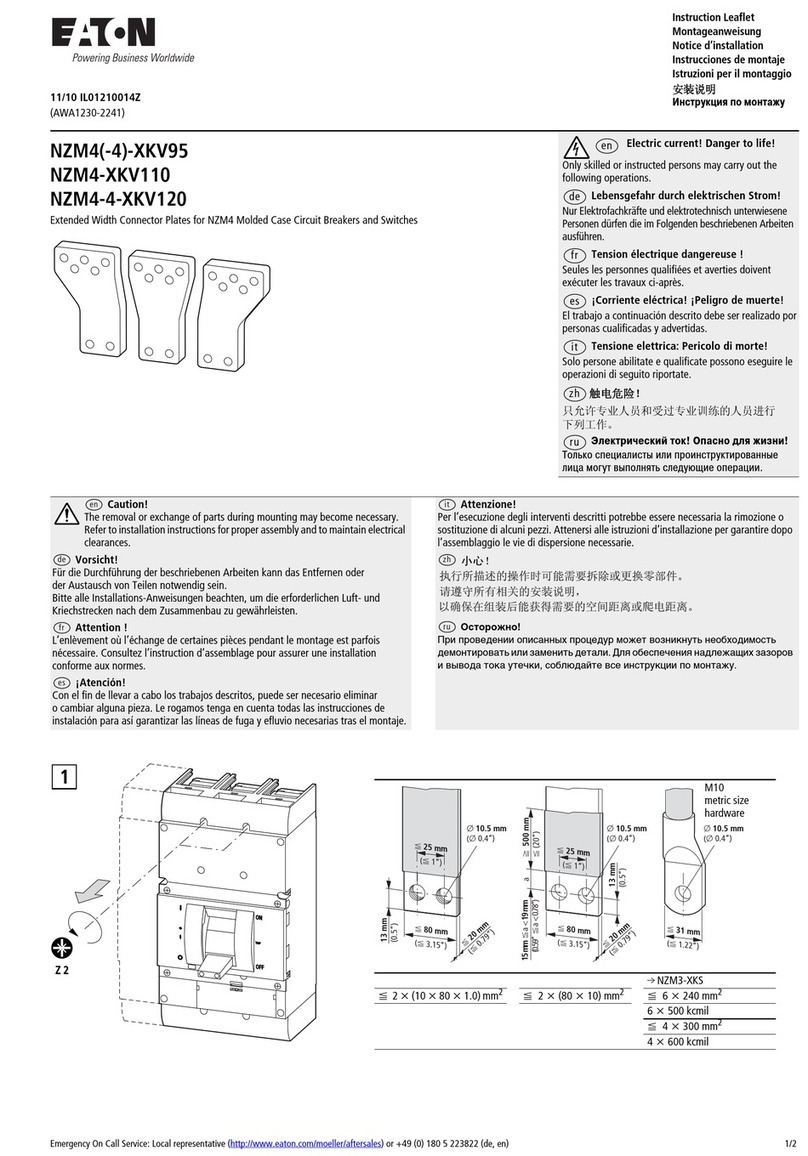

Eaton NZM4-XKV95 Manual

Eaton

Eaton AT4 Manual